4 Layout and Equipping

Layout

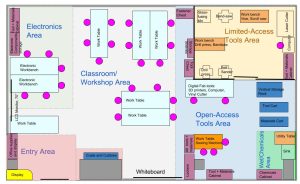

The spatial organisation of a makerspace is crucial to creating an environment conducive to creativity and learning. The makerspace needs to be adaptable, because the needs of the community can change over time. That is why the space should be zoned: divided into different zones for different types of activity. For example, have one area for electronics, another for woodwork, a collaborative workspace, and a storage area, etc.

Table 1: Description of the zones and workstations in a Makerspace

| Zones | Description | Workstation |

| Reception | This area is used to welcome members and visitors, provide information about the makerspace and its rules, and manage registrations and tool loans. | A single workstation could be sufficient to manage registrations, tool loans and information. |

| Co-working space / training area | This is a multifunctional space that can be used for meetings, training courses, workshops, presentations, group work or simply computer work. It can be equipped with modular tables, chairs, whiteboards, projectors, etc. | The number of workstations can vary greatly, depending on the size of the space. You might consider having enough space to host workshops or group training sessions. For example, a space that can accommodate 10 to 20 people might be a good place to start. |

| Electronics / robotics area | This area includes soldering workstations, development kits for microcontrollers such as Arduino or Raspberry Pi, electronic components, robots and more. | Depending on the size of the space, you could envisage having 3 to 5 workstations, each equipped with the necessary tools for electronic and robotic work. |

| Digital fabrication area | This area includes 3D printers, laser cutters, vinyl cutters, thermal presses, etc. Workstations for the preparation and post-processing of 3D prints can also be located here. | The number of workstations depends on the number of machines you have. Each 3D printer, laser cutter or other machine could be considered a workstation. The preparation and post-processing area could also be considered a workstation. |

| Woodworking area | This area includes woodworking tools such as circular saws, drill presses, planers, etc. It would also include a space for wood storage and finishing work. It would also include space for wood storage and finishing work. | Given the size of the tools and the need for space for woodworking, 3 to 5 workstations could be a good starting point. |

| Metalworking area | This area includes lathes, drilling machines, welding machines and other metalworking tools. It would also include space for metal storage and finishing work. | As with woodworking, 3 to 5 workstations could be appropriate, depending on the size of the space and the equipment available. |

| Textile/sewing area | This area includes sewing machines, embroidery machines, mannequins, a large cutting table and other sewing and textile supplies. | Depending on the space available, you could have 2 to 4 stations, each with a sewing machine, and a cutting and preparation area. |

| Storage area | This space is used to store materials, tools, ongoing projects, etc. | This area does not generally require dedicated workstations, but must be large enough to store materials and ongoing projects. |

| Security area | This area would contain safety equipment such as fire extinguishers, first-aid kits, safety glasses, gloves, etc. | This area does not require workstations, but must be easily accessible from any part of the space. |

| Relaxation area | A space to relax, eat and socialise. This can help encourage collaboration and the exchange of ideas between members. | The space required will depend on the number of members, but a small corner with a table and chairs for 4 to 6 people could be a good place to start. |

Picture 02: An example of space design and layout (source : Maker Resources for K-12 Educators)

Equipping

Most commonly, makerspace tools and materials cover eight areas: digital fabrication, electronic/robotic, textiles, woodworking, metalworking, computers and software, furniture and security, general tools.

Table 2 : Digital Fabrication Tools

| Equipment | Description |

| 3D Printer | These machines use plastic filaments or other materials to build three-dimensional objects layer by layer, based on a digital model. They are used to manufacture a wide variety of objects, from prototypes to functional parts. |

| Laser cutter | Laser cutters use a high-powered laser beam to cut or engrave materials. They can be used to create artwork, project components, information panels and more. |

| Vinyl cutter | These machines cut precise shapes from self-adhesive vinyl, which can then be applied to a variety of surfaces to create custom designs. |

| 3D Scanner | 3D scanners create digital representations of real objects, using light to capture the shape and sometimes the colour of the object. These digital models can then be modified, duplicated or analysed using other digital tools. |

| CNC Machines | CNC machines are used to machine materials by removing superfluous parts to create a specific shape. These machines use a router to cut, hollow out or engrave a wide variety of materials, including wood, metal, plastic and many others. They are often used for larger projects, such as furniture making or panel cutting. |

Table 3 : Electronic/robotic tools

| Equipments | Description | Example of a model |

| IoT kit | These kits generally contain a variety of electronic components and sensors to facilitate the development of IoT projects. | ESP8266 IoT Development Board |

| Robotic kit | Robotics starter kits, such as those from LEGO Mindstorms, Makeblock or VEX Robotics, which include motors, sensors and other components. | LEGO Mindstorms EV3 |

| Wireless modules | WiFi, Bluetooth, ZigBee, LoRa and other modules are essential for IoT and robotics projects requiring wireless communication. | ESP8266 WiFi Module |

| Breadboards | These tools are used to create and test prototypes of solderless electronic circuits. | Elegoo 830 points Breadboard |

| Motors and servos | DC motors, stepper motors, servo motors, etc. are commonly used in robotics projects. | Servo Motor SG90 |

| Resistors | Resistors are passive components used to resist electrical current in a circuit. They are often used to limit current, divide voltage, etc. | 220 Ohm resistors (1/4 watt, 5%) |

| Capacitors | Capacitors are energy storage devices. They store electrical energy when a voltage is applied and release it when it is disconnected. They are often used in filtering, control and coupling circuits, etc. | 100uF 25V electrolytic capacitor |

| Transistors | Transistors are semiconductor devices that can amplify or switch electronic signals and electrical energy. They are one of the fundamental building blocks of modern electronic circuits. | NPN 2N2222A Transistor |

| Diodes | Diodes are electronic components that allow current to flow in one direction only. They are often used to convert alternating current into direct current, protect circuits against overvoltage, etc. | Diode 1N4007 |

| LED | LEDs (light emitting diodes) are semiconductor devices that emit light when an electric current is passed through them. They are commonly used as indicators, in lighting, in digital displays, etc. | 5mm white LED |

| Connecting wires | Connection wires are used to make electrical connections between different components or modules in a circuit. They can be of different types, such as male-male, male-female, female-female, etc., depending on the connection requirements. | Dupont” type connecting wires, male to female, 20cm |

Table 4: Textiles tools

| Equipments | Description | Example of a model |

| Sewing machine | A device used to sew fabrics and other materials together with thread. | Brother CS6000i |

| Digital embroidery | These machines use design software to create complex embroidery patterns. The machines then use these designs to automatically embroider on materials such as fabric. | Brother PE800 |

| Heat press machine | These machines use heat and pressure to transfer patterns or images onto materials such as fabric. They are commonly used to make personalised t-shirts, caps, bags and more. | Fancierstudio DG Heat Press |

Table 5 : Woodworking tools

| Equipments | Description | Example of a model |

| Circular saw | Electric tools used to make straight cuts in wood. | DeWalt DWE575SB |

| Jig saw | Outil électrique utilisé pour couper des courbes dans le bois. | Bosch JS470E |

| Sanding machine | Used for a smooth wood finish | DeWalt DWE6423K |

| Planing machine | Used to flatten and reduce the thickness of wood. | DeWalt DW735X |

| Wood lathe | Used for woodturning work such as bowls, vases, balusters, etc. | JET JWL-1236 |

| Drill press | Used to drill precise holes to defined depths. | WEN 4214 |

| Routing machine | Used for a variety of cutting tasks, including grooves, edges and mouldings. | DeWalt DW618PKB |

| Set of hand tools | Basic tools used for various woodworking tasks. | hammers, chisels, saws, etc. |

| Work bench | A stable work surface for a variety of woodworking tasks. | Seville Classics |

Table 6 : Metalworking tools

| Equipments | Description | Example/model |

| Metal band saw | A metal bandsaw is used to cut different types of metal with precision. | JET JWBS-14DXPRO |

| Metal lathe | A metal lathe is used to machine the metal precisely. | JET GH-1440-1 |

| Milling machine | A milling machine is used to machine metal parts. | JET JMD-18 |

| Metal belt sander | A metal belt sander is used to polish and finish metal parts. | JET J-41002 |

| Anvil | An anvil is used as a hard surface on which metal can be shaped. | Grizzly G8147 |

| Welding unit | A welding machine is used to join metal parts by fusion. | Hobart 500559 Handler 140 |

| Hydraulic press | A hydraulic press is used to bend or shape the metal. | Sunex 5720 |

| Tapping arm | A tapping arm is used to tap holes in metal. | FlexArm A-32 |

Table 7 : Computers and software tools

Computers allow users to design and simulate projects before they are physically built. CAD (computer-aided design), 3D modelling and graphics editing software are essential for creating and modifying digital models. For the software to work optimally, the computers used in makerspaces need to have certain minimum features. The software most commonly used in makerspaces is summarised in the table below:

| Areas |

Software | Description | Open source? |

| CAD (computer- aided Design) / DAO (dessin assisté par ordinateur) | AutoCAD . | Used to create 2D drawings and 3D models | No |

| Fusion 360 | 3D design software developed by Autodesk. | No | |

| SketchUp | Easy-to-use 3D modelling software. | No | |

| SolidWorks | 3D design software for professionals. | No | |

| TinkerCAD | An excellent online 3D modelling tool for beginners. | No | |

| Digital fabrication | Cura | 3D printing software developed by Ultimaker. | Yes |

| Repetier-Host | Une solution d’impression 3D complète qui permet de contrôler et de gérer les tâches d’impression. | Yes | |

| CAMotics | Une simulation pour les machines CNC 3 axes. | Yes | |

| GRBL | Un firmware pour les contrôleurs de machines CNC. | Yes | |

| Electronic/robotic | Arduino IDE | A development environment for programming Arduino boards. | Yes |

| Raspberry Pi OS | An operating system for the Raspberry Pi. | Yes | |

| Fritzing | Electronic circuit design software. | Yes | |

| KiCad | Open-source software for designing electronic schematics and printed circuits. | Yes | |

| Design | Adobe Creative Cloud | Software suite including Photoshop, Illustrator, Premiere Pro, After Effects and more. | No |

| GIMP | Free, open-source image-editing software. | Yes | |

| Inkscape | Free software for designing vector graphics | Yes | |

| Coding | Visual Studio Code | A code editor developed by Microsoft. | Yes |

| PyCharm | An integrated development environment for Python | Yes | |

| Node.js | A runtime environment for server-side JavaScript | Yes | |

| Unity | A game engine for the development of 2D and 3D games | Yes | |

| Interactive learning | Scratch | A programming platform for children. | Yes |

| MakeCode | A coding environment for beginners designed by Microsoft. | Yes |

Furniture and security

- Furniture: Choose furniture that is flexible and adaptable to suit different activities. Adjustable tables and chairs, storage shelves and whiteboards can be useful.

- Security

- Safety: Put safety measures in place, including fire extinguishers, first aid kits and personal protective equipment. Make sure users are trained in safety.

- Waste management: Set up waste and recycling bins, and consider waste management strategies for materials used in the makerspace.

- Storage: Provide storage solutions for tools, materials and ongoing projects. Shelves, lockers and storage bins can help keep the space organised.

Table 8: General tools

These are the basic tools for carrying out various projects and tasks in a makerspace. They are versatile and can be used in many different types of projects, from woodwork to metalwork, electronics and more. It is also important to train users in the correct way to use these tools and to stress the importance of following good safety practices.

|

|

|

Obtaining all of the equipment that you might need for your makerspace may seem like a daunting task. Here are few tricks that you can use to keep the costs as low as possible (Make App Club Team, 2018):

Tricks to keep the costs low

- First of all, you should be aware that the making you can do in your space, and therefore skills you can develop, will be determined by the equipment and resources you have available. You can start small with the basics in one particular area, and grow as your demand grows.

- Make use of used/donated items rather than buying things new. Call upon your existing network to see what might be available. You might be surprised by how generous people can be.

- Make use of auction sites like eBay to buy second-hand and to secure the best deal. Online shopping comparison sites can also point you towards some bargains.

- Particularly early on, it makes sense to borrow what you can – especially if the piece of equipment is only going to be used for a small amount of time. It also gives you the option to road test equipment before working out if it is worth purchasing.

- It is also possible to raise money for new equipment through fundraising. This could be an excuse for a group project. For example, young makers could create a Christmas gift that could be sold to raise funds.

- Whenever possible, try to work with free software. This gives people the opportunity to access that software at home and to continue to work on it for free.

- The final way to gain equipment is to bid for it through trusts and charitable institutions.