11 Outcome 3: Underground Distribution Systems

Section Information

Outcome/Competency: You will be able to describe underground distribution systems.

Timing: 2h

Rationale:

Why is it important for you to learn this skill?

Powerline technicians must sometimes work on powerlines located underground. It is imperative that they know how to access these powerlines safely to avoid injury, death, or property damage.

Objectives:

To be competent in this area, the individual must be able to:

- Identify and describe common underground powerline components

Learning Goals

- Identify and describe common underground powerline components

Introduction:

In this module you will learn about cables and conductors, wire types, take-off structures, pedestals, and underground transformers. You will be presented with content and then given opportunities to test your understanding with short review exercises.

Topic: Cables and Conductors (30m)

Instructions:

- Cover the following content as a group (either reading out loud or independently) then give an opportunity to answer any questions.

- Have students do the review questions independently, then take up answers.

Underground

The underground distribution is divided into two areas: high voltage (primary) and low voltage (secondary)

Primary

High voltage cable uses a copper or aluminum conductor, depending on the load it will carry. They are under no tension or strain, so strength is not a consideration. Normally, #2 solid aluminum is used.

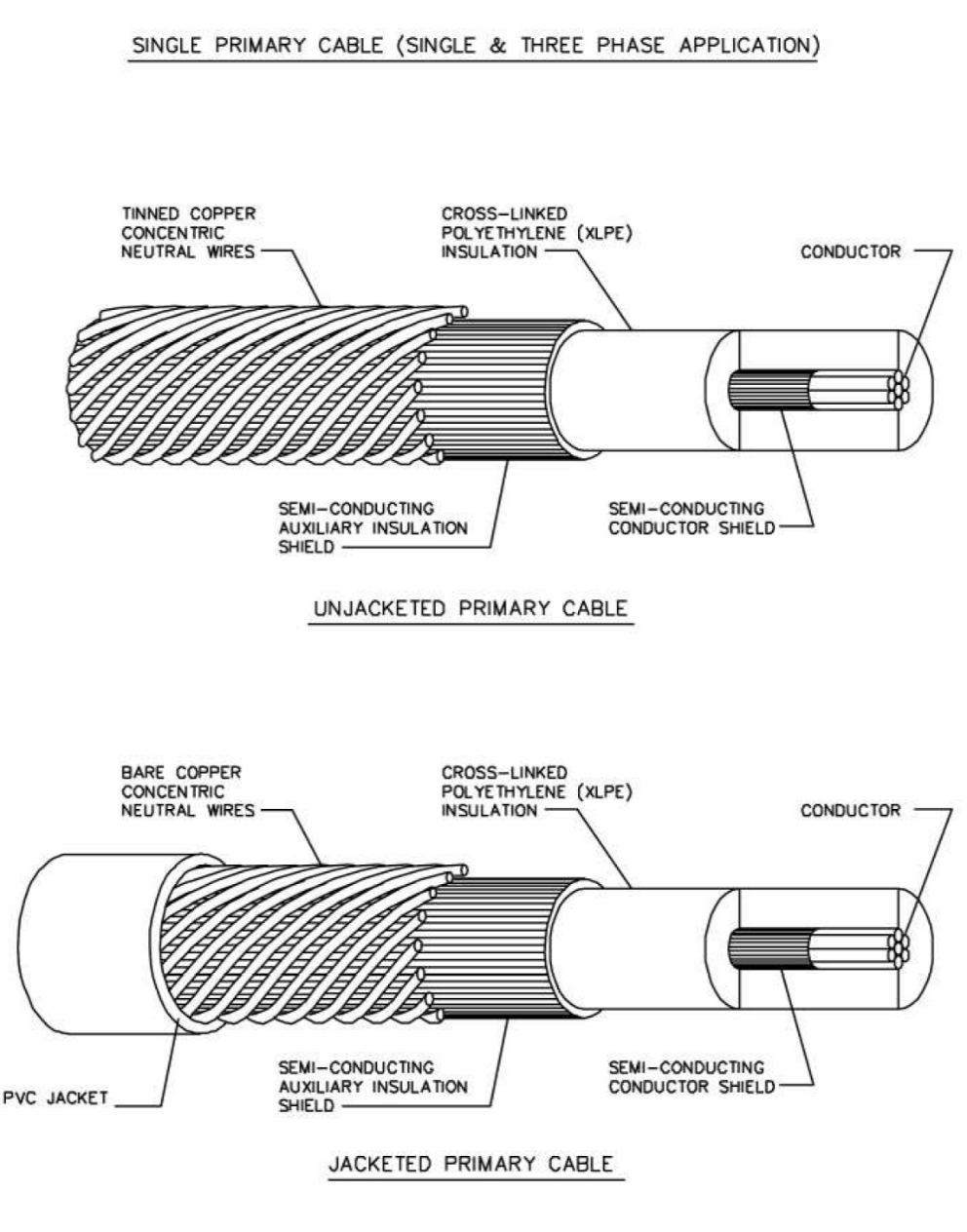

Since the underground cable is under high voltage (14,400 volts and up), it has a large amount of insulation. The neutral on this cable surrounds the insulation to further protect the cable from damage.

Secondary

Like primary cable, secondary underground cable is made from either aluminum of copper. Once a load gets very large, copper is considered.

Like overhead secondary, it also has one neutral and one or more conductors to form Duplex, Triplex or Quadruplex. In underground cables though, the neutral is covered with the same insulation as the conductors to protect it from moisture and damage. The neutral is required to be the same size as the conductors, unlike overhead construction since the air cannot take the heat away from it.

Conductor Sizes

Conductors are sized with three different units. They are in order from smallest to the largest:

- Numbers – #44 (smallest) to #1 (largest)

- 1/0 to 4/0 (also shown as straight zeros – 4/0 = 0000)

- Kcmil (250 – 2000)

Knowing the conductor size is very important. A conductor that is connected to a sleeve or insulink which is too large will always result in a poor connection and failure.

Knowing the conductor size is very important. A conductor that is connected to a sleeve or insulink which is too large will always result in a poor connection and failure.

When crimping sleeves and insulinks, we must remember that stranded or ACSR conductor has spaces between the strands. Therefore, these conductors will use a larger size sleeve than a solid conductor of the same size. For example, a #4 ACSR conductor will use the same insulink as a #2 solid conductor.

Wire Types

Conductors come in many different types of configurations. Solid conductors consist of 1 wire, while stranded conductors are made up of more than 1 wire, increasing flexibility. Compact and compressed conductors are stranded conductors that have less space between the wires to form a smaller cable for underground construction. This makes it important to identify and the cable properly (usually written on cable jacket) and select the proper connector.

Splicing underground conductors

Splicing underground secondary is similar to overhead conductors. Wire brushing is always done and care must be taken when trimming the insulation so the conductor is not nicked or cut.

Underground is always spliced using a sleeve, not crimps or taps. Also, the sleeves must always be rubber taped, then plastic taped, to protect the conductor.

When splicing underground cables having a water jacket, be sure to strip the outer jacket further back than the insulation (as per the Construction Standards Manual). Copper sleeves on ground wires are an exception.

When splicing underground cables having a water jacket, be sure to strip the outer jacket further back than the insulation (as per the Construction Standards Manual). Copper sleeves on ground wires are an exception.

When splicing underground cables having a water jacket, be sure to strip the outer jacket further back than the insulation (as per the Construction Standards Manual). Copper sleeves on ground wires are an exception.

Splicing underground primary is done according to individual manufacturer’s instructions.

Review Questions: Cables and Conductors (20m)

- List, in order, the conductor sizes from smallest to largest:

- 250 kcmil

- 4/0

- #8

- 00

- #2

- Match the statements on the right to the terms on the left.

|

____ It has reduced spaces between wires. |

|

____ It consists of one wire. |

|

____ This is never used on underground. |

|

____ It is made up of several wires. |

Answer Key

1. 5,4,1,3,2.

2. b ,a ,c , d.