22 Outcome 1: Hand Tools

Section Information

Outcome/Competency: You will be able to use and maintain hand tools

Timing: 3h

Rationale:

Why is it important for you to learn this skill?

Powerline technicians need to use a wide range of hand tools as part of their day-to-day jobs. The proper selection, maintenance, and use of hand tools helps ensure the safety of yourself, your colleagues, and others around you. This can avoid injury and death caused due to tool malfunction or incorrect use.

Objectives:

To be competent in this area, the individual must be able to:

- Explain how to identify, select, and use hand tools

- Explain how to clean, store, and maintain hand tools

Learning Goals

- Explain how to select, use, and maintain hand tools according to manufacturer’s specifications and company policies

Introduction:

In this section you will learn about the six main personal PLT tools (Lineman body belt tools, crescent wrench, screwdriver, rulers and tape measures, skinning knife, and ball peen hammer), as well as learn about different kinds of cutters. You will be presented with theoretical content and given an opportunity to see and hold some of these tools. You will then be given short review exercises to test your understanding so far.

Instructions:

- Cover the following content in each topic as a group (either reading out loud or independently) then give an opportunity to answer any questions.

- As you discuss each tool, give students an opportunity to hold the tool. Where possible, demonstrate how the tool is used. Ensure all proper PPE is used and safety should always come first.

- Have students do the review questions independently, then take up answers, and answer any questions.

Topic 1: Six Main Personal PLT Tools (1h)

Lineman Body Belt Tools

This plier is sometimes called a Klien, named after the manufacturer of this line of tools. It has only one purpose – to cut wire.

If the pliers open and close hard, they can be loosened. Here’s how:

- To loosen, place the pliers on a solid surface with the cutting edge up. Using a punch and hammer, tap the centre rivet lightly, checking for stiffness after each tap.

- To tighten, follow the same procedure, except this time the cutting edge is down against the solid surface.

Make sure the two cutting edges are sharp and not chipped. The cutting edges should be parallel. If light is visible between the cutting edges when the pliers are closed, the pliers may not cut completely. The insulated handle covers should be replaced of not intact.

Crescent Wrench or Adjustable Wrench

Proper care and maintenance will keep the tool working correctly for years.

If the jaws are not snug on the nut or bolt, the wrench might slip, and you could injure yourself.

Check the locking screw in the worm gear. The screw sometimes needs to be tightened with a screwdriver.

Use light oil or graphite powder to lubricate the worm gear and the sliding lower jaw.

The solid portion of the wrench is designed to take most of the load when you are turning a nut or bolt.

Screwdriver

There are two types of screw drivers which are generally used in the line trade- the flat blade is for slotted head screws, and the “Robertson” is for square, recessed slot screws.

This is a tool with one purpose only- to drive a screw into wood or sheet metal. Always use the right size driver for the job. The tip of the blade must not be damaged, or it may slip on the screw head.

A screwdriver has a metal shank with a composite handle, as the handle provides electrical insulation. The metal shank must not pass through the handle or be exposed.

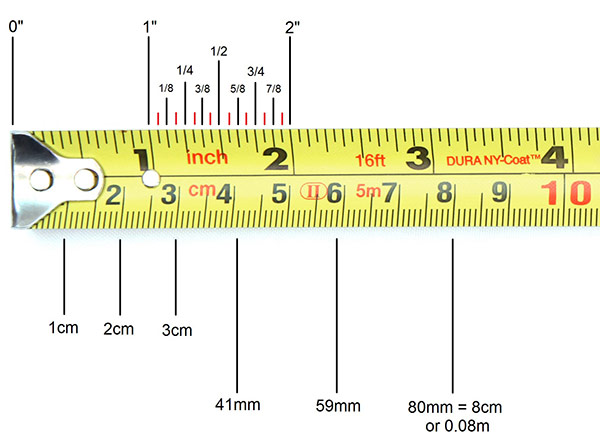

Rulers and Tape Measures

|

|

The spring joint folding lineman’s ruler is made of a nonconductive material without metal-reinforced edges. It is the only ruler approved for use on overhead line work such as measuring between bolt locations.

Here are some basic rules about the measuring devices.

- Always keep the ruler clean

- A ruler must not be made of metal or have metal edges.

- Numbers and gradations must be clearly legible. Measurements are in inches and centimetres.

- Don’t bend or stress the joints

- Store where it will not be damaged

Skinning Knife

The skinning knife, used for stripping the insulation from a wire, resembles a common linoleum knife with the tip cut off.

The skinning knife is a special tool manufactured for the line trade. It must always be sharp and free from nicks along the cutting edge; otherwise, you might damage or weaken the conductor. Sharpen with a file not with a grinder. Do not over sharpen: a knife that is too sharp may damage the conductor.

Like all sharp instruments, care must be taken when using this tool.

Ball Peen Hammer

The ball peen hammer is used for driving lag screws and staples. One end has a ball shape and the other a flat surface. The handle is made of wood or fiberglass and must never be taped because it might conceal a crack in the handle and become a hidden safety hazard. If the handle is cracked, replace it.

If the hammer face becomes burred, remove the burrs with a file. If the head is too badly “mushroomed” and chipped, replace it.

Wear gloves and safety goggles/glasses when using a hammer.

Topic: Cutters (1h)

Bolt Cutter

Bolt cutters are commonly used for cutting copper and aluminum wire and soft bolts.

To adjust the alignment of the bolt cutter, loosen the locking nut on the side of the handles with a crescent wrench. Using an allen wrench, adjust the recessed screws located above the locking nuts on the handles.

Adjust the cutters until light is just visible between the cutting edges when the handles are closed. You may

have to do this two or three times.

Before using, clean the cutter and lubricate with either light oil or graphite. Wipe off excess oil.

Don’t force the tool as this may damage the cutter.

Never twist or turn the cutter or apply a “cheater bar” to extend the leverage. Apply the appropriate size cutter for the task.

The jaws on a bolt cutter differ from a wire cutter in that there is one flat sided jaw .It should be noted that the jaws on this tool can be replaced if necessary.

Wire Cutters

|

|

The wire cutter is beveled on both sides of the jaws to aid in cutting stronger materials.

The wire cutter is like the bolt cutter in general appearance and maintenance. The wire cutter, however, is used on tougher materials such as guy wires and conductors with steel cores.

The wire cutter is like the bolt cutter in general appearance and maintenance. The wire cutter, however, is used on tougher materials such as guy wires and conductors with steel cores.Wire cutters must be serviced and lubricated for best performance. Inspect the cutting surfaces for alignment and chipping.

It should be noted that the jaws on this tool can be replaced if necessary.

Cable Cutters

Cable cutters are almost like bolt cutters except the jaws are curved or hooked.

Cable cutters are strictly for cutting softer conductors such as copper and aluminum cables, including the lead sheathing around a cable. These are soft cutters and will be damaged if used on steel reinforced conductors.

Cable cutters are strictly for cutting softer conductors such as copper and aluminum cables, including the lead sheathing around a cable. These are soft cutters and will be damaged if used on steel reinforced conductors.Before using, clean the cutter and lubricate with a light oil or graphite. Wipe off the excess oil.

It should be noted that the jaws on this tool can be replaced if necessary.

Review Exercises: Hand Tools (1h)

- From the list below, circle the tools you would find on a properly equipped lineman belt: (you may choose more than one item.)

- Richo jack

- Ball peen hammer

- Metal tape measure

- 9 inch lineman pliers

- Flat screwdriver

- Crescent wrench

- Robertson screwdriver

- Skinning knife

- Match the tools shown (in the left column) with the descriptions listed (in the right column.) (Some tools may apply to more than one description, while other tools may not match any of the descriptions.)

- Richo jack

- ____ Common length is 2m (6 ft)

- Ball peen hammer

- ____ Metal shank must not pass through handle.

- Metal tape measure

- ____ In order to loosen or tighten its operation, tap the rivet

- 9 inch lineman pliers

- ____ Should not be used as a chisel or pry bar

- Flat screwdriver

- ____ Solid portion to take the majority of the load

- Crescent wrench

- Robertson screwdriver

- Skinning knife

Precision tools such as lineman pliers and crescent wrenches should never be used as a _______________. These tools should always be kept clean and lubricated with _______________ or _________________.Match the type of cutter (in the left column) with the most appropriate description (in the right column.) (You may choose more than one type of cutter for some of the descriptions.)

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Answer Key:

1. b, d, e, f, h

2. no match, e, d, e, f

3. Hammer, light oil, graphite

4. b, c, a, a, c, b, a and b, b, a and b, a, c