16 Outcome 3: Live Line Tools

Section information

Outcome/Competency: You will be able to use live line tools.

Timing: 1.5h

Rationale:

Why is it important for you to learn this skill?

Powerline technicians will have to sometimes work with live lines, this means lines that conduct electricity. It’s important that powerline technicians understand the principles of live-line work so that they can safely use, care for, and maintain these lines without injury, death, or destruction of property.

Objectives

To be competent in this area, the individual must be able to:

- Demonstrate basic knowledge of principles of live-line work using live-line tools (hot sticks)

Learning Goals

- Demonstrate safe use, care, and maintenance

- of live-line tools

Introduction:

In this section you will learn about the safe use and maintenance of hot sticks, grip-all sticks, and telescopic sticks. You will be presented with content and then given an opportunity to test your understanding with short review exercises.

Instructions:

- Cover the following content in each topic as a group (either reading out loud or independently) then give an opportunity to answer any questions.

- Have students do the review questions independently, then take up answers.

Topic: Basic Hot Sticks (1h)

A well-built, well maintained hotstick possesses three very important characteristics:

- High di-electric strength

- High physical strength

- Lightweight

One of the most important things to remember when using and handling hotsticks and hotstick accessories, is to keep them free of moisture and dust. Never lay live line tools on the ground unless they are placed upon a clean, dry tarpaulin. If possible, live line tools and accessories should remain in the truck or tool trailer unit until needed.

It is the responsibility of the Powerline Technician, for their own safety, to make sure the hotstick is kept absolutely clean and in good working condition.

It is the responsibility of the Powerline Technician, for their own safety, to make sure the hotstick is kept absolutely clean and in good working condition. The use of hotsticks and the regular maintenance needed to keep them in good operating condition is extremely important.

The use of hotsticks and the regular maintenance needed to keep them in good operating condition is extremely important.Each tool should be inspected regularly for metal and fiberglass fatigue or excessive wear from frequent use. Look for bent rivets or bolts, scratches, cracks or other signs of damage. Operate the tool several times, if applicable, to make certain it functions as smoothly and unobstructed as it is intended to. Inspect the surface for scratches, gouges or cracks that should be repaired.

Ensure the inspection due date sticker is valid, if applicable. If necessary, send the hotstick tool to be tested.

Do not use the hotstick tool if:

- The inspection due date sticker is invalid.

- The tool is damaged.

- The condition of the tool is in doubt.

If the hotstick tool has any foreign material on it such a creosote or grease, clean it with an appropriate detergent and flush clean with water.

Before any live line tool is applied to energize conductors, it must be wiped down with a silicon impregnated cloth. Start at one end of the insulated hotstick handle and work your way down to the other end of the handle. Do not wipe the cloth up and down the length of the insulated handle; instead, rotate the cloth around the handle, slowly moving along its total length and following the direction of the fiberglass fibers. Clean the entire surface, every crevice.

This procedure is important to maintain the di-electric properties of the hotstick; otherwise, dust and moisture may allow current to flow along the surface of the hotstick.

Grip-all Hotstick

This unit is stored in a canvas bag in a safe place out of the weather when not in use to keep it clean and to protect it from damage. It is folded in half for storage and opens to full length for use.

Before starting to use the hotstick on site, inspect all moving parts. Check for an inspection due date sticker to ensure that it is valid. Never use a stick with an expired due date.

Check rivets, pins, the jaw and all moving parts. Operate the hotstick two or three times to make certain everything works smoothly. Ensure the jaw will close as designed.

Inspect the surface for cracks and damage to the fiberglass epoxy. A special silicon-impregnated cloth must be used to thoroughly wipe the fiberglass coating. Clean every crevice. This is important to maintain the di-electric properties of the hotstick because dirt and moisture may allow current to flow along the stick.

When using the grip-all hotstick, hook the jaw into the eye and slide the handle back past the safety stop. Loosen the clamp and fully retract the handle. The operator now has complete control of the hotline clamp.

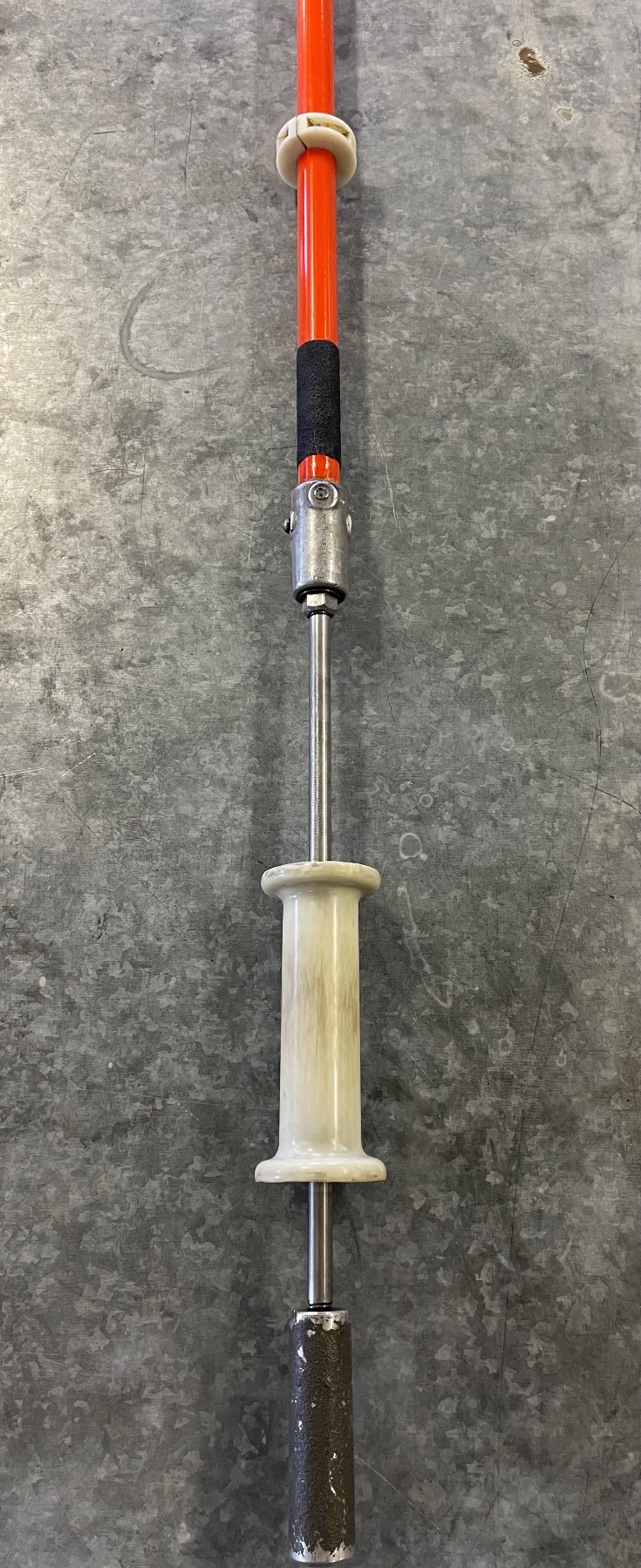

Telescopic Hotstick

As with all hotline tools, careful maintenance is essential for safety. Check all working parts such as the locking buttons and top connection. Carefully examine to find flaws along the entire length.

|

Clean the hotstick by wiping the entire length with silicon cloth. Clean every crevice on the entire hotstick. When you are finished using the hotstick, ensure cleanliness and replace it in the canvas bag for storage.

|

|

|

Review Exercises: Live Line Tools (30m)

- List the three characteristics a well-built hotstick possesses.

- Do not use a hotstick if: _________________________________________, _______________________________________, __________________________________.

- Before any live line tool is applied to an energized conductor, it must be __________________ down with a ___________________________ cloth.

- __________________________ and ________________________ may allow current to flow along the surface of the hotstick.

- ( T / F ) If the inspection due date on a grip-all hotstick is expired, you may continue to use the stick if it appears to be clean.

- ( T / F ) Before using a grip-all hotstick, it must be inspected for proper operation, tight rivets, and thoroughly wiped with a silicon cloth.

- ( T / F ) Hotsticks are to be stored only in a hotstick trailer.

- ( T / F ) Hotsticks can be used beyond the test date if they appear to be in proper working condition.

- Explain the proper method of storing a hotstick

Answer Key

- High physical strength, Lightweight , High di-electric strength

- Inspection due date sticker is invalid, Tool is damaged, Condition of tool is in doubt.

- Wiped, Silicone impregnated

- Dust, Moisture

- False

- True

- False

- False

- In the canvas bag, stored in a safe place out of the weather