25 Outcome 5: Rigging, Hoisting and Lifting Equipment

Outcome/Competency: You will be able to describe the use and care of rigging, hoisting, and lifting equipment

Timing: 2h30

Rationale:

Why is it important for you to learn this skill?

Working with ropes and cables can be dangerous if done incorrectly. Technicians must learn how to select the right rigging, hoisting, and lifting equipment for the job including following any applicable regulations, and understanding load limits. They also need to ensure that they understand how to regularly inspect slings to ensure they are still functioning correctly. This knowledge can help prevent severe injury or even death.

Objectives:

To be competent in this area, the individual must be able to:

- Given the Saskatchewan OH&S Regulations, determine if rigging apparatus satisfies established guidelines

Learning Goals

- Identify and explain relevant OH&S regulations which pertain to rigging.

- Determine the working load limits of fibre rope and nylon slings.

- Describe the guidelines for sling inspections.

Introduction:

In this module you will learn about various rigging equipment, safety factors, working load limits, wire rope, fiber rope, nylon slings and inspection and replacement of ropes. You will be presented with concepts and given opportunities to see and touch some of the different equipment. You will then have an opportunity to test your understanding with short review exercises.

- Cover the following content in each topic as a group (either reading out loud or independently) then give an opportunity to answer any questions.

- Have students do the review questions independently, then take up answers.

Introduction (5m)

All rigging is to be assembled, used, maintained, etc., in accordance with manufacturer’s specifications. All rigging is to be done under the supervision of a competent worker who has been trained in safe rigging practices.

The general provisions set forth by Saskatchewan Occupational Health and Safety inspection is the employer’s responsibilities. Because it will be the employee using the rigging, these provisions pertain to the employee more than the employer. The person(s) using the rigging is responsible for ensuring the regulations are being followed. Listed below are some definitions and provisions which pertain to rigging.

Definitions (15m)

Rigging

Rigging is any combination of rope, wire rope, slings, sheaves, hooks, etc., that are used in a hoisting operation.

General Requirements

All rigging is to be assembled, used, maintained, etc., in accordance with the manufacturer’s specifications.

All rigging is to be done under the supervision of a competent worker who has been trained in safe rigging practices.

Inspections

All rigging and components are to be visually inspected before use and at appropriate intervals as recommended by the manufacturer.

Maximum Loads

The maximum load for rigging used to raise or lower a worker is 10% of the breaking strength.

In the case of other rigging, the maximum load that may be imposed is 20% of the breaking strength.

The maximum loads for rigging, where practical, is to be marked on the rigging or the information must be made available to the workers.

Slings

Any sling used to hoist a load has to be suitable for the application of the sling.

Slings are to be arranged in a manner which prevents any part of the load from slipping or falling.

Slings are to be guarded to prevent damage to the sling.

The sling is not to be used if it has been or may be damaged.

Topic: Rigging Equipment (10m)

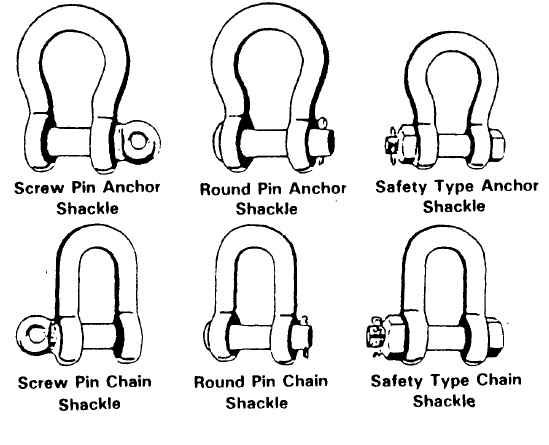

Shackles

Figure 14 Shackles Attr. SaskPower Training Manual

Figure 14 Shackles Attr. SaskPower Training Manual

Never exceed the working load limit (S.W.L.)

Install all the pins to prevent accidental withdrawal. Never use a bolt in place of the proper pin.

Sheaves, Spools and Drums

The sheaves, spools, and drums are matched to the manufacturer’s specifications of the rope being used.

The rope is to be fastened securely with the recommended full wraps remaining on the drum. If the manufacturer’s recommendations are unavailable, at least five full wraps must remain on the drum.

Topic: Safety Factors and Working Load Limits (5m)

Safety information for rigging inspections, wire rope, and shackles is found in the Saskatchewan Occupational Health and Safety (OH&S) regulations.

Do not use the factor of safety as reserve strength for additional capacity. The safety factor must not be used for additional capacity.

Topic: Wire Rope (5)

The safe working factor for wire rope is 5 to 1 (or 20%) of the manufacturer’s breaking strength. This safety factor is for material handling only.

A general rule of thumb for determining the safe working load of wire rope is:

Safe Working Load (in tons) = (Diameter in Inches)2 X 8

Example:

Consider a 9/16 inch wire rope.

9162×8=2.526tonsor5052lbs.

Remember: to convert a fraction to a decimal, divide. (9 ÷ 16)

If the object lifted exceeds this weight, you will have to 2-part your line.

Topic: Fiber Rope (20)

The same standards apply to fibre and wire rope. A 5 to 1 safety factor must be applied to the breaking strength of the rope.

Safe Working Load (in lbs.) = Manufacturers Breaking Strength ÷ 5

Example:

Consider a 1 inch (Herzog) double braid nylon rope.

33,000 lbs. divided by 5 = 6600 lbs.

If lifting objects over this weight, you will have to 2-part your line.

Example:

Consider ½ inch (Herzog) double braid nylon rope.

8300 lbs. divided by 5 = 1660 lbs.

Topic: Nylon Slings (15m)

Most slings used are nylon. Where practical, all slings are to have the safe working load labelled on them, or this information made available to the user.

Check the brand of sling you are using for the safe working loads.

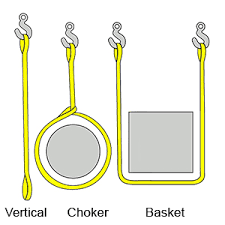

Examples of Sling Configurations

Figure 15 attr. cranemaxfl.com

The recommended safe working angle on a sling is 60 degrees. If possible, slings should not have less than a 45 degree angle on them because of the stress that is put on the sling.

For example, when using a single sling to hang a transformer, you now have a basket with legs inclined. Because the legs are inclined, you will have to determine how much sling stress is on each leg.

Topic: Inspection and Replacement of Ropes and Slings (45m)

Wire Rope Inspection

A wire rope inspection is one of the most important checks and serves several purposes:

- It ensures safety.

- It ensures that components will be replaced only when necessary.

- It provides advance warning before something breaks resulting in severe damage or bodily harm.

Wire rope is to be totally inspected before use. If not being used for an extended period of time, follow the manufacturers recommendations.

Rope Replacement Guide

A guideline for replacement is as follows:

- Six randomly broken wires in one rope lay

- Three broken wires in one strand in one rope lay

The usual requirement for replacement is if the outer wire wear exceeds 1/3 of the original diameter of the wire ropes outside individual wires.

A guideline for nylon rope replacement is as follows:

- Acid or alkali burns

- Melting, charring or weld splatters

- Excessive abrasive wear

- Knots in any part of the rope

- Distortion and excessive pitting or corrosion

- Any other apparent defects which cause doubt as the strength of the rope.

Inspections of ropes and slings is the responsibility of the person or persons using them.

Review Exercises: Rigging, Hoisting and Lifting Equipment (30m)

- When using rigging for hoisting material, the safety factor is:

- 10% of the breaking strength

- 15% of the breaking strength

- 20% of the breaking strength

- If there are no manufacturer’s recommendations, how many full wraps must always remain on the winding drum?

- 3

- 5

- 7

- A rule of thumb for determining SWL of wire rope is:

- Diameter x 8

- Diameter squared x 6

- Diameter squared x 8

- When determining the safe working load of nylon rope, you must:

- Divide the manufacturers breaking strength by 8

- Divide the manufacturers breaking strength by 6

- Divide the manufacturers breaking strength by 5

- Match the correct sling configuration with the correct graphic.

- Choker

- Basket

- Vertical hitch

- The replacement guide for broken wires is:

- Six broken wires in one rope lay

- Three broken wires in one rope lay

- Two broken wires in one strand.

- Inspections of slings is the responsibility of:

- The employer

- The person/persons using them

- The occupational health and safety committee

- ( T / F ) A nylon sling with one knot in it can be used for rigging a transformer.

Answer Key

1. c, 20%

2. b

3. c

4. c

5. b, a, c

6. b

7. b

8. f