Topic 6 – Framing with Steel Studs

Steel Studs

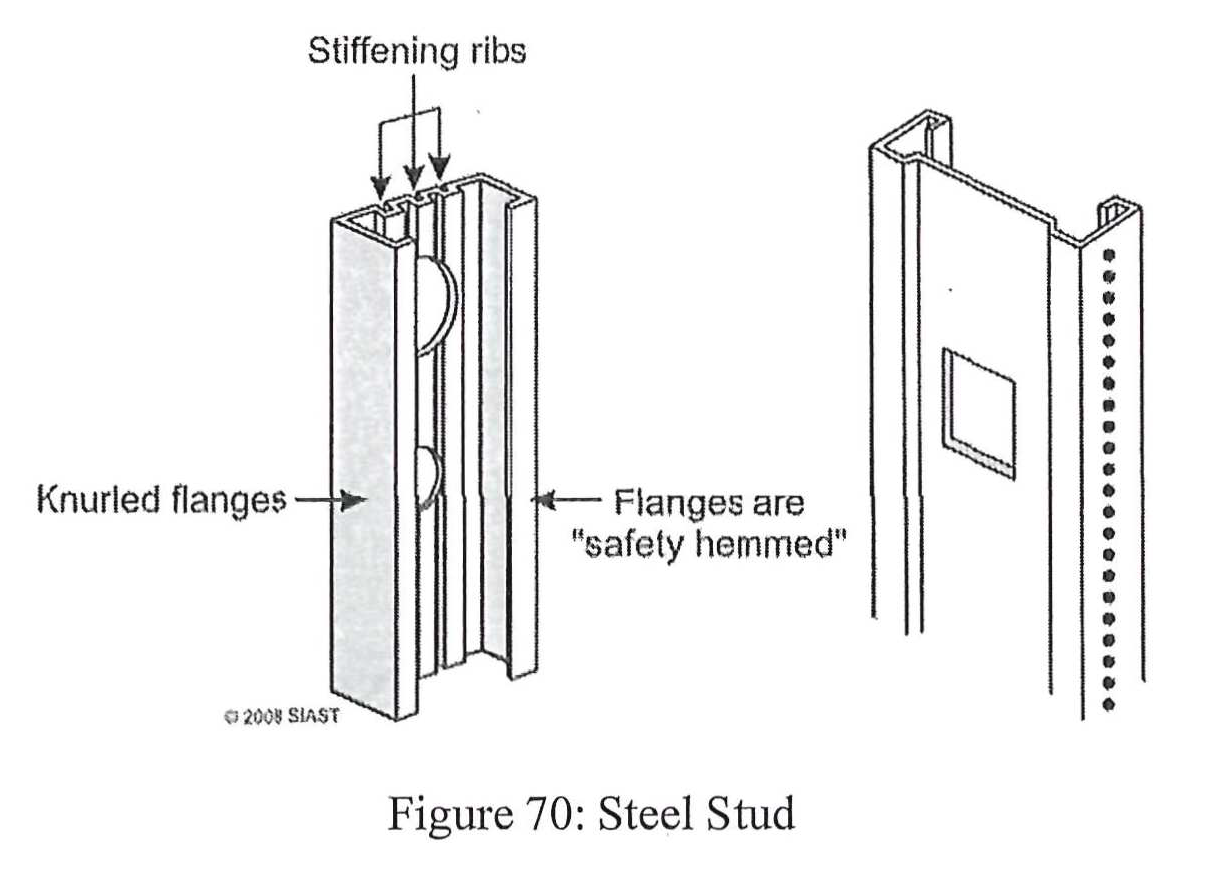

Steel stud framing consists of a channel shaped top and bottom runner which act as the top and bottom plates in which the steel studs are placed. Steel studs lack the rigidity of wooden studs and must be cladded or sheathed on both sides, with some exceptions.

Made of galvanized steel, they are manufactured from different thicknesses of metal, known as gauge. In the case of steel studs, the lower the gauge value, the thicker the material is. Studs and runners are available in a variety of lengths ranging from 2400 mm (8’) to 8000 mm (36’). They are also available in a variety of widths from 1 5/8” – 6”. The flanges can be 1 1/8” – 1 3/8” and contain a knurled face which assists in both grabbing screw points and provides a textured surface for glue to adhere to.

Steel studs are also equipped with punchouts that are oriented in predetermined locations to facilitate the feeding of electrical and mechanical components, and T-holes which receive stiffener bars.

Due to their composition, steel studs do not warp or twist due to changes in humidity. The thin nature of the material produces a wall that, when insulated, provides superior sound and insulating properties that have a high fire resistance rating. They do, however, expand with temperature changes which must be considered when framing. Often a ¼” (6 mm) is left between the stud and the top flange of the upper runner to allow expansion. Due to their lack of rigidity, steel studs are also not permitted to be used in load-bearing applications.

Due to their composition, steel studs do not warp or twist due to changes in humidity. The thin nature of the material produces a wall that, when insulated, provides superior sound and insulating properties that have a high fire resistance rating. They do, however, expand with temperature changes which must be considered when framing. Often a ¼” (6 mm) is left between the stud and the top flange of the upper runner to allow expansion. Due to their lack of rigidity, steel studs are also not permitted to be used in load-bearing applications.

Layout of Steel Stud Framing

While steel studs share principles with wood framing, there are specific considerations that must be made, and methods used that differ from wood framing. The primary difference with steel studs is they are framed in place, usually around a load-bearing frame.

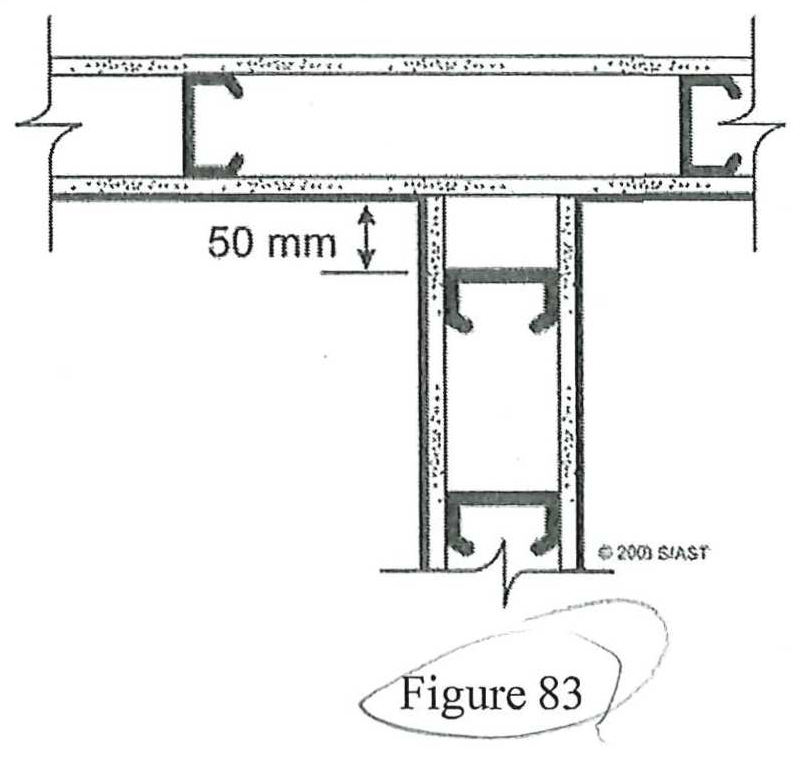

The bottom runner is the first piece that is installed when framing with steel studs. It can be located by centers or by a building’s outer dimensions. Interior partitions may also be indicated by a rooms inside dimension. In any case, proper deductions must be carefully made to ensure proper placement. Much like wood framing, the edges of the bottom runner are located, and a chalk line snapped to show the edges of framing. The bottom runner is cut short and omitted at door openings. It may also be cut short of wall intersections to allow drywall to pass behind (see figure 83). The bottom runner is attached using a variety of methods that are chosen based on base material.

The bottom runner is the first piece that is installed when framing with steel studs. It can be located by centers or by a building’s outer dimensions. Interior partitions may also be indicated by a rooms inside dimension. In any case, proper deductions must be carefully made to ensure proper placement. Much like wood framing, the edges of the bottom runner are located, and a chalk line snapped to show the edges of framing. The bottom runner is cut short and omitted at door openings. It may also be cut short of wall intersections to allow drywall to pass behind (see figure 83). The bottom runner is attached using a variety of methods that are chosen based on base material.

Top runners are installed immediately after the bottom runner. It can be located using a straight edge and level, plumb bob, or plumb laser. Care must be taken to ensure the correct side is located when marking the top runner. Unlike wood framing, joints in the upper and bottom channels are not required to be on a stud center. If possible, channels should be overlapped at intersections.

Cutting and Installing Steel Studs

Steel studs are typically cut in bulk to save time. When assembled, a gap of ¼” (6 mm) or ½” (12 mm) for fire-rated walls is required where the stud meets the top plate. When cutting studs in bulk it is important that all measurements are taken from the same end of each stud and the cut end is consistently placed during assembly. This ensures that all knock-outs will be oriented together to allow stiffeners or electrical wires to pass through. The studs should be installed plumb with all flanges facing the same direction. They are screwed or crimped in place at the specified centers.

Framing Openings

Framing Openings

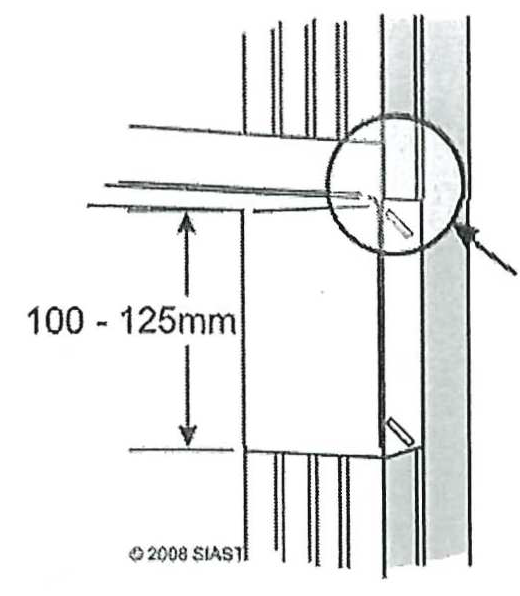

Openings in steel stud walls are framed similarly to wood. A double or triple stud is required on each side, depending on the opening width. The header is fabricated from piece of runner stock which is cut 8-10” longer than the opening to allow it to be bend over 4-5” (100-125 mm) and fastened to the adjacent studs (see image right). Fire rated walls require this lap to be 6” (150 mm) minimum (see 9.24.3.2).

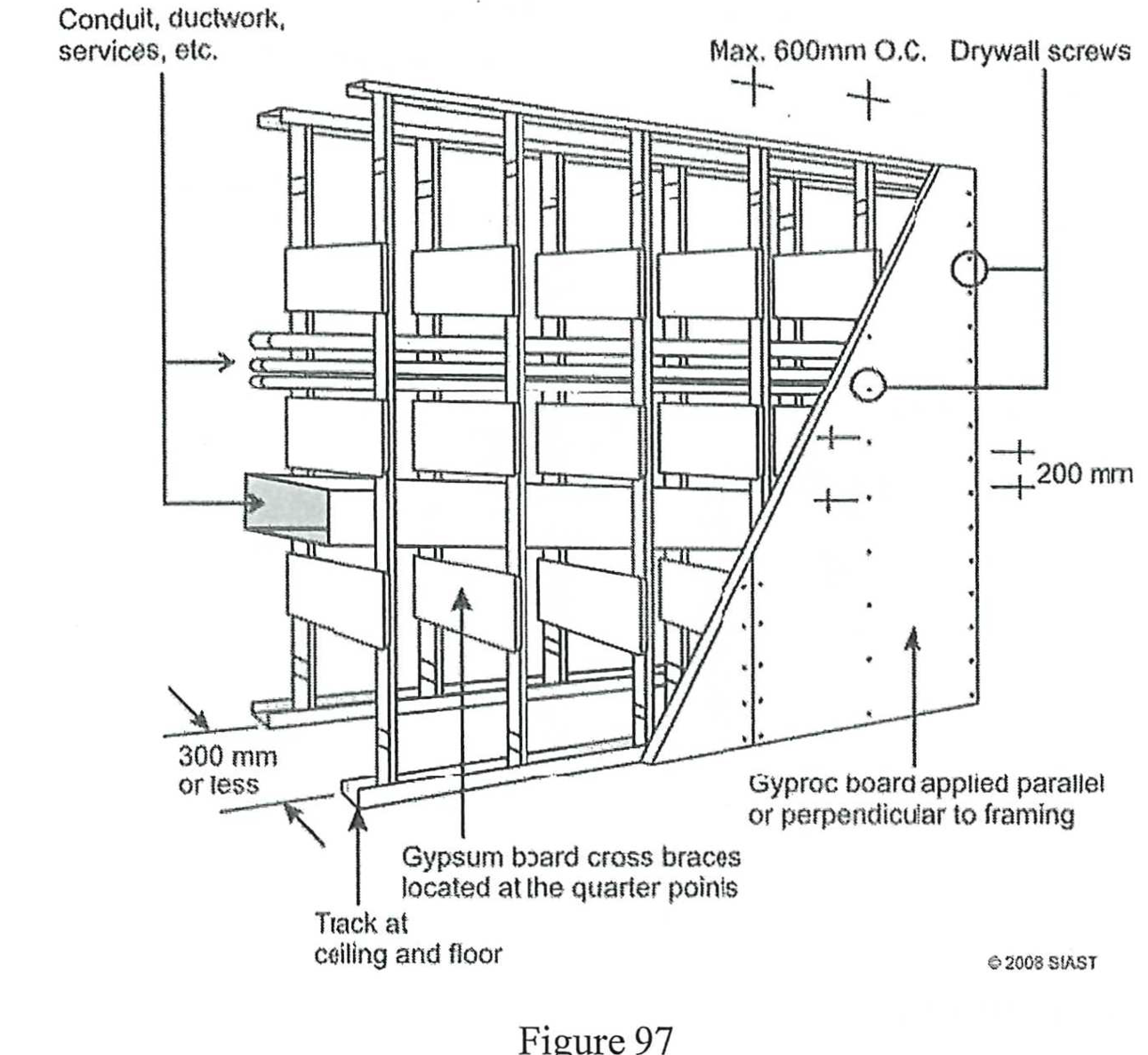

Framing Double and Chase Walls

Double walls are sometimes constructed to enclose large pipes or clusters of pipes. If the space between the walls is 12” or less, they are tied together using strips of ½” gypsum board that are 12” wide. When this space exceeds 12”, they must be clad on both sides as independent walls (see figure 97 below).

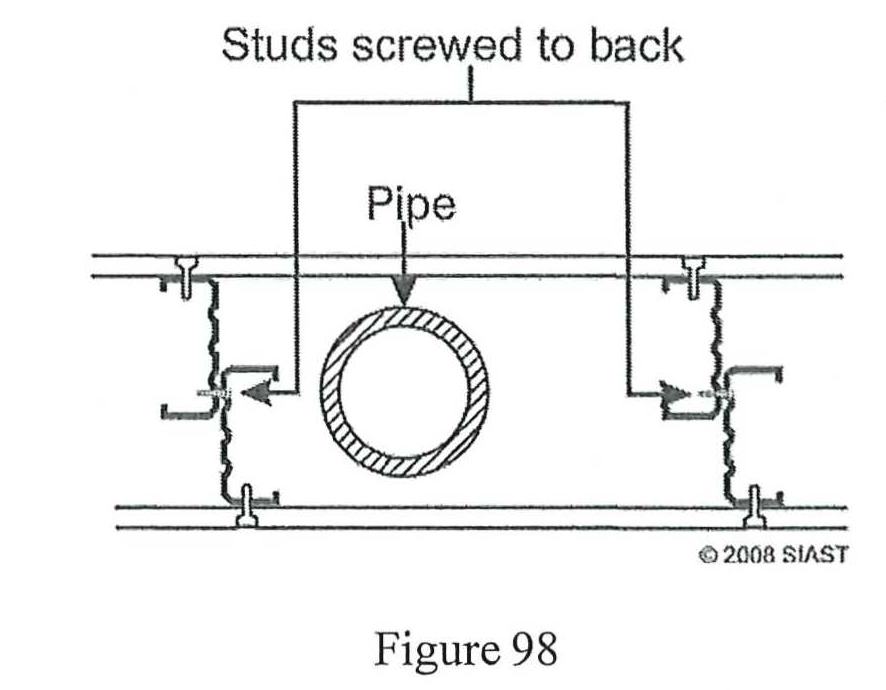

Chase walls may also be framed to enclose plumbing pipes. To achieve a space greater than nominal widths, studs are fastened back to back (figure 98 right).

Cornice-Height Partitions

Cornice height partitions (also known as pony walls) are free standing walls. As they do not have the upper support most walls are provided, they must be equipped with a continuous cap piece composed of wood. Any cornice-height partition which is not braced by intersecting partitions, corners, or ceiling extensions should be no longer than 8”0” (2400 mm). To help with stability, fasteners in the runner should alternate from one edge to the other to help prevent tipping.

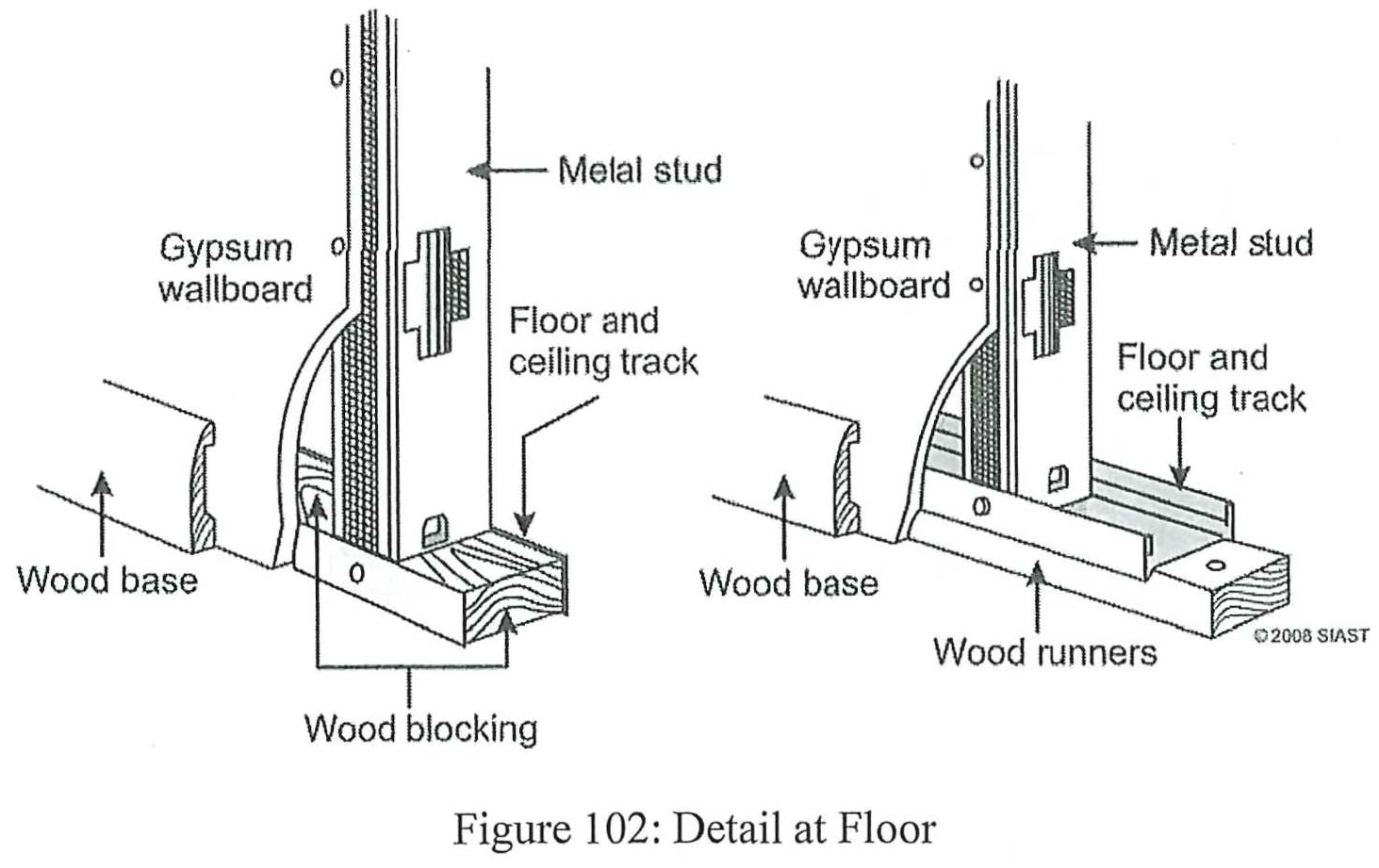

Base and Casing Attachment

To provide adequate backing for trim work, 38 mm material can be placed where necessary. The bottom runner may be fasted over a continuous piece of 38 mm stock or may be filled with blocks between each stud space to provide material which can be nailed into. Blocking may also be filled in a similar manner around door and window openings to provide backing in a similar manner for trim work.

Review Questions

Review Section 9.24 in the NBC to answer the following

- 32 x 64 steel studs for a wall 3800 mm high may be spaced not more than ___ mm O.C.

- What size steel studs would be used for a wall 5 m high if they are spaced 400 mm O.C. (non load-bearing partition).

- If a non load-bearing partition in a fire separation has an opening of 900 mm width, the steel stud must have a metal thickness of at least _____ mm.

- The flanges of a metal runner for non-load-bearing partitions must be at least _____ mm wide.

- In a partition that is required to have fire rating, the maximum distance from the first stud to the jamb of any door is _____ mm.

- If the distance above an opening to the top runner is more than 400 mm, intermediate support shall be installed at intervals not exceeding _____ mm above the opening (fire rated wall).

- Describe the requirements for framing an opening in a steel stud fire-rated wall.

- Runners must be attached to the building at approximately 50 mm from the ends and at intervals not exceeding _____ mm for an interior partition and _____ mm o.c. for exterior walls.

- If an opening exceeds 2400 mm in width, the studs must be ____.

- 30 x 91 mm steel studs, 0.69 mm thick at 400 mm o.c. may have a maximum length of _____ (non-load bearing exterior walls).

- The upper runner of the double runner required above door openings with steel door frames in fire rates walls shall be bent at each end to extend upward not less than _____ mm.

- True or False:

- Steel stud framing shall always be clad on both sides.

- A runner is required only on top of the walls.

- For space saving purposes, steel studs may be placed on the flat, attaching the sheathing to the web.

- The bottom runner is installed continuously across the door openings and cut out later.

- When cutting steel studs and runners, use a framing or combination square to ensure an accurate cut.

- Explain two methods that can be used to provide for nailing base trim to walls using steel studs.

- What is one important consideration to make when cutting and installing steel studs?

- How can steel studs be eliminated at corners and intersections and still have adequate backing for gypsum board?

- If a partition, not full ceiling height, is stiffened with floor-to ceiling height steel studs, the stiffeners should be placed at least at _____ mm intervals.

Answers:

- 400 mm (9.24.2.1)

- 32 x 89 (9.24.2.1)

- 0.46 mm (9.24.2.4-1b)

- 30 mm (9.24.2.3-1)

- 400 mm (9.24.2.4-3)

- 400 mm (9.24.2.4-4)

- 12 mm clearance from stud to top channel, studs attached to allow for expansion, headers required to be double runners fastened back to back, overlapping the adjacent stud by 150 mm, gypsum filler piece required between the door frame and adjacent runner (9.24.3.2)

- 600 mm, 300 mm (9.24.3.1-2(2))

- Tripled (9.24.3.5-1)

- B

- 150 mm (9.24.3.2-4)

-

- False

- False (9.24.3.1-1)

- False (9.24.3.3-1)

- False

- False, cuts need not be accurate

- A continuous wooden runner or blocking between studs in the channel runner.

- Cut the same end on each and orient them the same inside the wall to ensure the knock-outs line up.

- Drywall passes by the intersecting wall and is fastened in place, the last stud it brought in place after drywall is installed.

- 3000 mm