Chapter E7 – Installs Roof Coverings

Key Competencies

The NOA for Carpenter (2013) identifies the required competencies for the task of installing roof coverings. These are:

- Select and use tools and equipment such as staplers, chalk lines, knives, metal shears, air nailers and hammers

- Select roofing materials such as asphalt shingles and metal according to site requirements, conditions and specifications

- Secure metal roofing materials such as corrugated and steel tile according to specifications

- Secure wood roofing materials such as shakes and shingles according to building code and manufacturer’s specifications

- Secure asphalt roofing materials such as shingles and rolled roofing according to manufacturers’ specifications

- Install starter strip, drip edge, flashing and caulking according to site requirements, conditions and specifications

- Install ridge and hip caps according to specifications (NOA, p. 59).

Topic 1 – Apply Asphalt Shingles

Asphalt shingles are rated by their life expectancy which is determined by their weight.

Installation

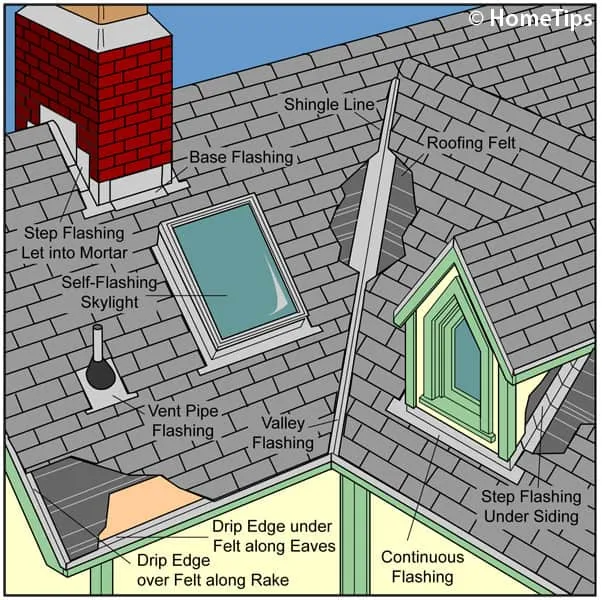

Below is a brief summary of the installation process for more detail study the recommended readings. Drip edge flashing is installed along the roof edge at the eave and up the rake working from the bottom towards the peak. Eave protection and underlay is placed over top of the drip edge. Chalk lines are used to mark the layout of the first course of shingles on top of the underlay. A starter strip is applied at the roof edge. Shingles are applied starting at the rake of the roof and working towards the peak with each course overlapping the row below. Installation of 3-tab shingles can be done using the straight up or stair step method. Valley flashings should be installed over the starter course. Application of shingles in the valley may be:

- Open

- Closed

- Woven

Special attention to layout is needed when shingling around a dormer on intersecting roofs to ensure the courses on the main roof line up. Step flashing is placed in between courses where the roof meets a wall.

Source: https://www.hometips.com/repair-fix/skylight-flashing-leaks.html

For more information review the following:

- Carpentry “Flashing” Chapter 57

- Canadian Wood-Frame House Construction study “Roof Coverings”

- National Building Code of Canada section on roofing

Review on Brightspace:

ROOF 200/220 Roof Coverings:

- IS 2.2 Apply Asphalt Shingles (p. 19 – 30)

Review Questions

- How many nails are used per full 3-tab asphalt shingle? For architectural shingles?

- How wide must the first layer of mineral-surfaced roll roofing be when used as flashing for an open valley?

- Closed valleys shall not be used with rigid shingles on slopes of less than _____.

- True or False:

- Valleys must be provided with flashings with either asphalt or wood shingles or roll roofing.

- Flashing at wall intersections must be installed in conjunction with each row of shingles.

- At what rate does the valley exposed width increase as you go down the valley?

- When doing a closed valley, how far should the shingles be extended onto the adjoining roof section?

- How are the shingles applied in a woven valley?

- The minimum slope of roofs is:

- _____ for asphalt shingles (low slope application).

- _____ for wood shingles

- _____ for hand-split shakes and asphalt shingles (normal application)

- When is a cricket or saddle required behind a chimney?

- What is the main difference in the application of low slope shingles as compared to the regular three tab?

- Where is step flashing used?

- Where is counter flashing used?

- Name three types of valleys

- The flashing at the valleys should be applied over or under the starter strip.

- Calculate how many bundles of asphalt shingles are required to shingle a roof which is 11’ x 21’ on each side. There are 3 bundles for each 100 sq ft, and with 10% for waste, starter course and ridge cap.

Answers:

- 4 nails for each

- 457 mm (9.26.4.3-5)

- 1 in 1.2 (9.26.4.3-3)

-

- True

- True

- The open valley increases in width of 10 mm per meter on each side as you go down the roof.

- The shingles should extend at least 300 mm.

- You weave each alternate course across the valley and over one another.

-

- 1:6

- 1:4

- 1:3 (Table 9.26.3.1)

- If a chimney is more than 750 mm wide, a cricket or saddle is required behind it. (9.26.4.8-1)

- A continuous band of roofing cement is applied under each shingle. The width of the band of cement should be 50 mm wider than the shingle exposure. (9.26.8.4)

- Where a roof meets a wall or chimney along the rake.

- Goes over top of the step flashing and is used when a roof meets a brick or masonry wall. The counter flashing is embedded in the mortar joints of the brick and overlaps the step flashing.

- Open, closed, and woven.

- Over.

- 15.25 so round up to 16 bundles needed.