Identify Procedures for Operating Portable Sanders

Topic 8 – Identify Procedures for Operating Portable Sanders

Disc Sanders

Disc sanders are primarily used for rough finishing and stripping of paint or varnish. It can also be used for shaping and sanding curved surfaces. While their operation and appearance is similar to an angle grinder, they produce much slower rotational speeds.

Disc sanders are primarily used for rough finishing and stripping of paint or varnish. It can also be used for shaping and sanding curved surfaces. While their operation and appearance is similar to an angle grinder, they produce much slower rotational speeds.

Figure 5: a portable disc sander

The sanding discs are attached to a rubber backing by either a retaining screw and washer or by adhesive. The diameter of the sanding disc should correspond to the diameter of the backing pad. Due to the rotational sanding action, cross-grain scratches are unavoidable. When operating the sander, it is important to maintain control by keeping both hands on the tool and avoid using excessive pressure.

Orbital and Oscillating Sanders

Orbital and oscillating sanders are primarily used for finish sanding. Depending on the type chosen, the sanding action is either oscillating or orbital. The orbital sander is preferred as it is able to sand material faster than its oscillating counterpart. Due to the random sanding action, the orbital sander produces cross-grain scratches, however this is not noticeable when approaching higher grits.

Orbital and oscillating sanders are primarily used for finish sanding. Depending on the type chosen, the sanding action is either oscillating or orbital. The orbital sander is preferred as it is able to sand material faster than its oscillating counterpart. Due to the random sanding action, the orbital sander produces cross-grain scratches, however this is not noticeable when approaching higher grits.

Figure 6: a 5″ random orbital sander

As with hand sanding, it is recommended to start with a lower, coarser grit and progressively move up to higher grits. The sanding disc is attached to the orbital sander using a Velcro attachment, whereas the oscillating sander retains the sheets with clips.

Belt Sanders

Belt sanders are most commonly used when large surfaces need to be smoothed or stripped of material. They can be used in both rough and finish carpentry applications. The belts are sized according to width (2”, 3”, and 4”) and length (21-27”). When replacing the belt, it is imperative that the rotational direction is followed, indicated by an arrow under the backing (some belts are universal).

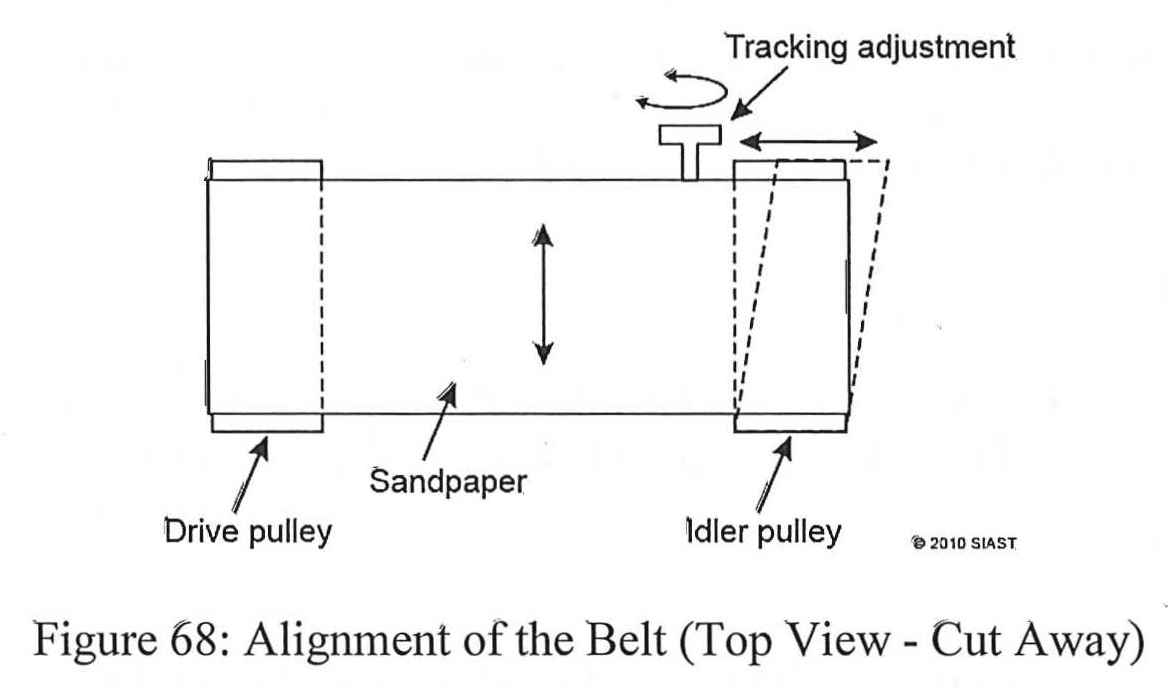

The belt of the sander is held in place by two pulleys, an idler and driver pulley. The idler pulley is able to retract to remove and accept a belt. In order to contain the belt centred on the tool, the idler pulley is equipped with a tracker, which rotates the pulley in and out (see figure 68).

The belt of the sander is held in place by two pulleys, an idler and driver pulley. The idler pulley is able to retract to remove and accept a belt. In order to contain the belt centred on the tool, the idler pulley is equipped with a tracker, which rotates the pulley in and out (see figure 68).

When operating the belt sander, it is important to not put pressure on the tool. It is designed to do the work under its own weight, and any extra pressure will put unnecessary strain on the motor and can cause premature clogging of the sandpaper. As the tool rests on its moving belt, both hands must be placed on the tool while its being operated, and the belt must come to a full stop before setting the tool down.

Safety When Sanding

Safety glasses and dust masks should always be worn when operating a power sander. Ensure the proper guards are in place and the dust collection bag (if on the tool) is cleaned regularly and kept empty. Never light matches in a room filled with dust as the dust particles suspended in the air may spontaneously combust/explode.

Review Questions

- Name two types of finish sanders. Which one is preferred and why?

- Putting excessive pressure on a disc may cause what?

- How is the size of a belt sander determined?

- How is the belt on a belt sander held in place and aligned?

- How much pressure should be applied when operating a power sander?

- All sanding should be done _______ the grain.