Describe How to Assemble and Use Metal Scaffolding

Topic 3 – Describe How to Assemble and Use Metal Scaffolding

Frame Scaffolds

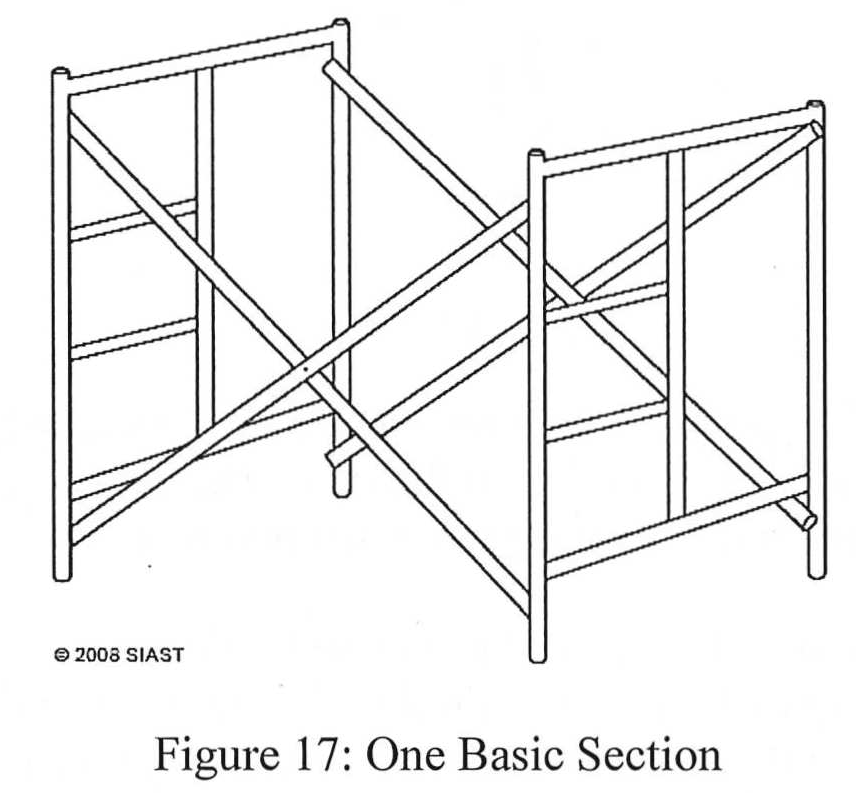

Frame scaffolds are the simplest and most common type of metal scaffolding. They consist of a frame and braces. While they are limited in straight assemblies, the quick and simple assembly time makes it the most popular option for scaffolding.

When building frame scaffolds higher than one section they must be joined by a coupler pin. If the scaffold is going to be moved, such as with castors, the pins must be secured by a pin or bolt to prevent it from slipping out.

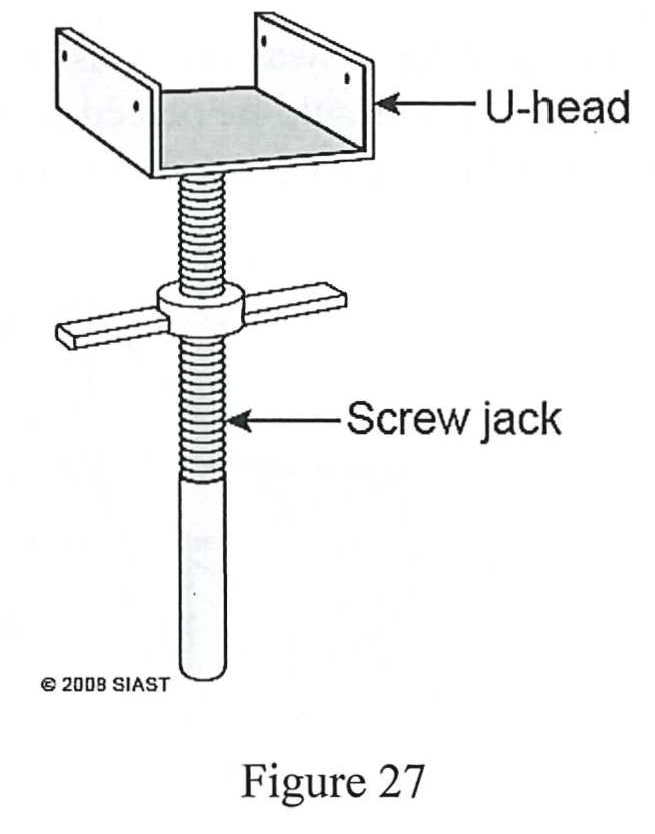

When erecting the scaffold over uneven terrain, an adjustable base jack must be used in conjunction with a mud sill. The scaffold should be plumb and level prior to building on additional courses. The procedures described in instruction sheet 4.03.1 such as guardrails and toe boards apply.

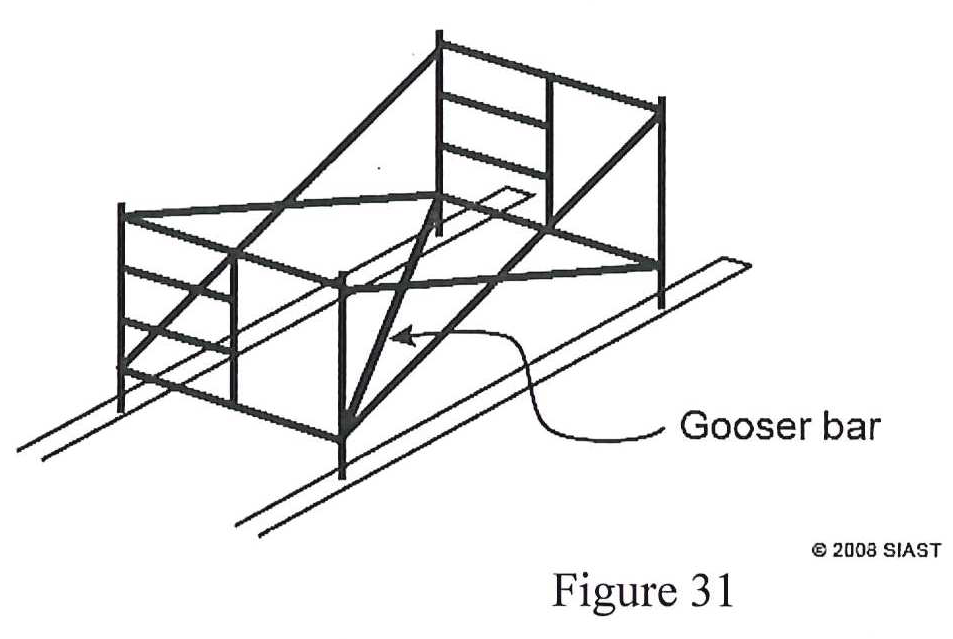

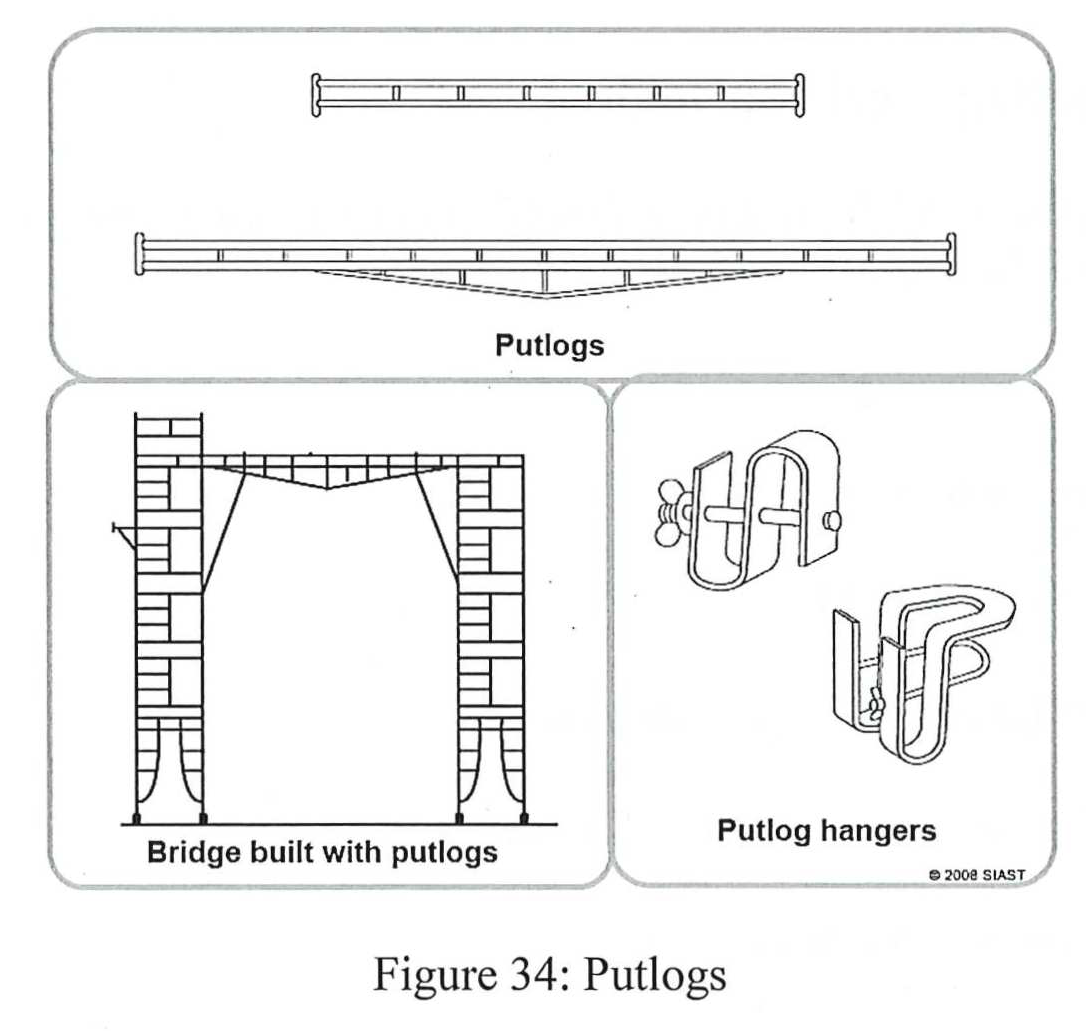

There a number of special components used with frame scaffolding, with a few discussed below:

Frame Scaffold Safety

Modular (All-Around) Scaffolding

Also known as systems scaffolding, it is similar to tube and clamp and is able to be built around irregular shapes. The vertical legs have rosettes in which the runners and bearers are connected to. While it is simpler to erect, it is not as versatile as tube and clamp.

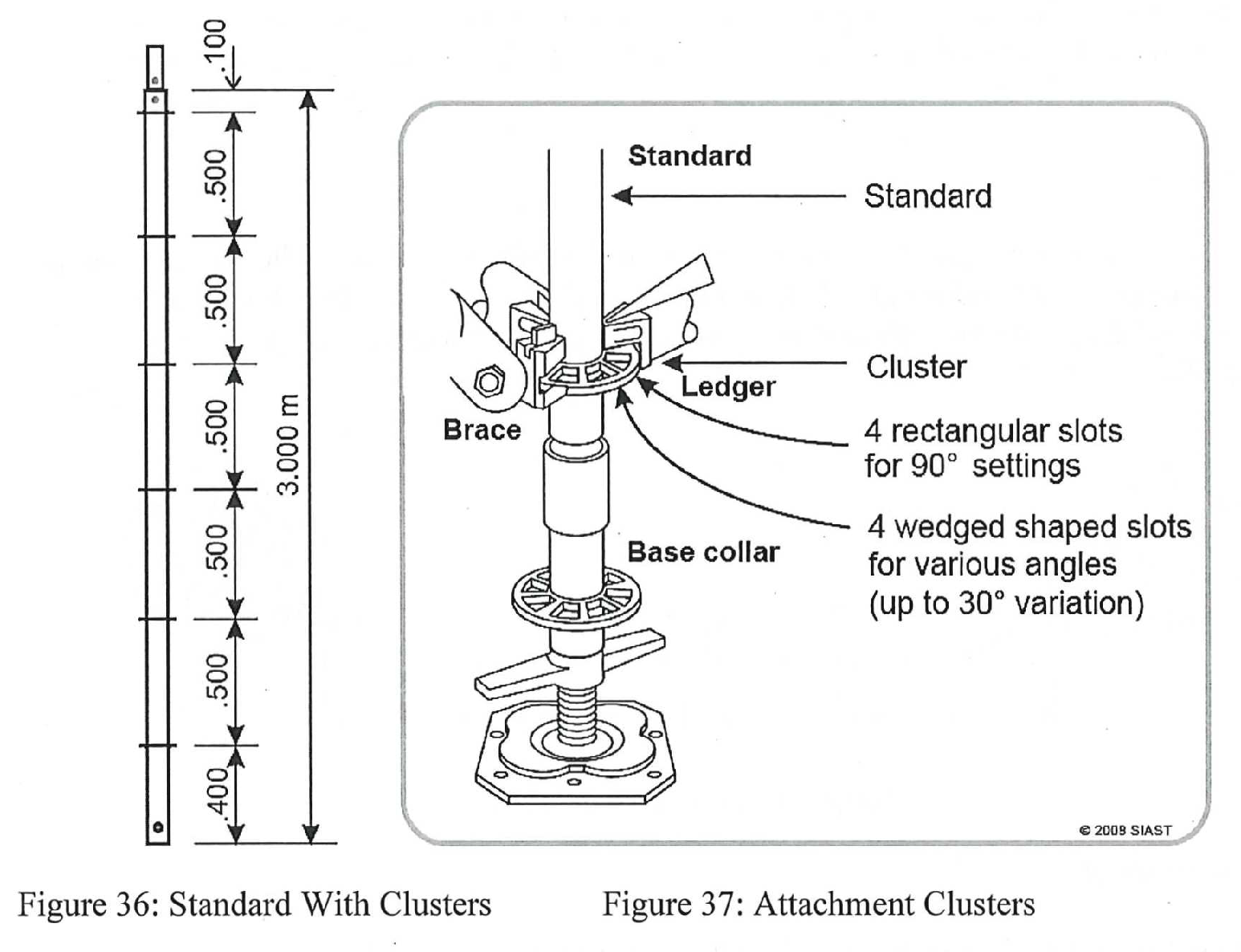

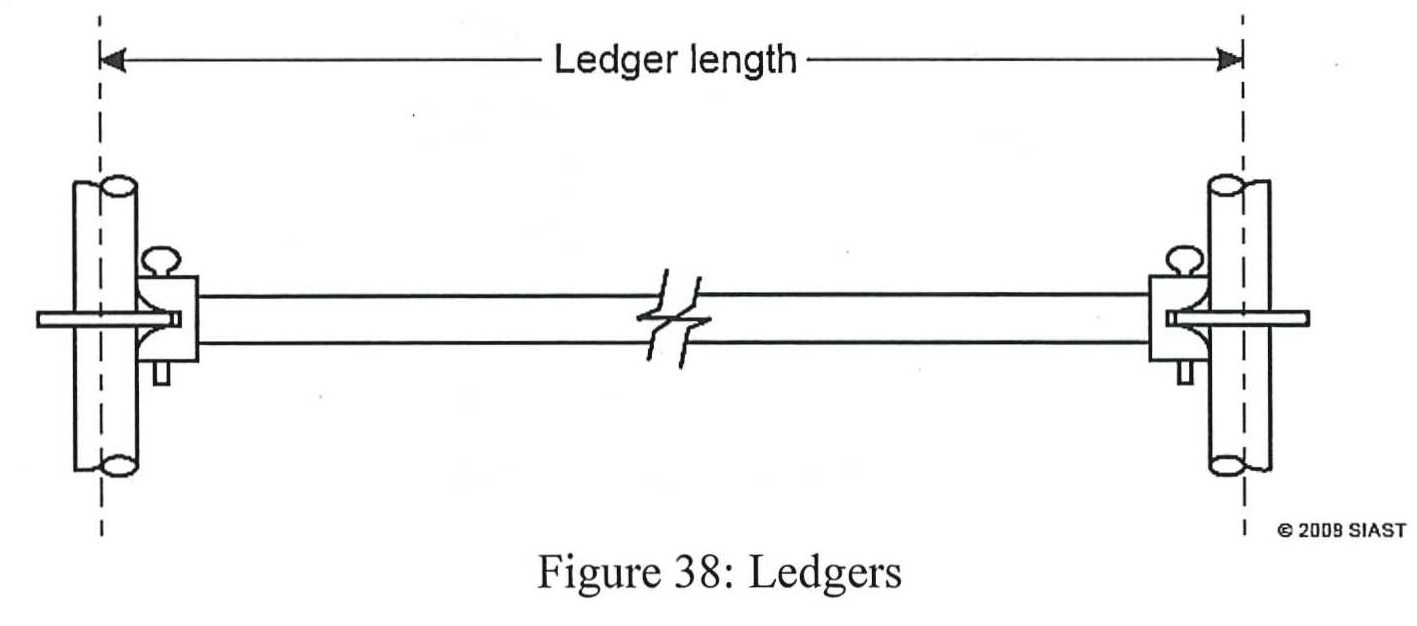

There are four primary components that make a modular scaffold:

- Cantilever brackets – Increases the width of the work platform

- Ladders – attached to transoms for access

- Stairs – Special stairs that are manufactured to attach to modular scaffolding

Dismantling Modular Scaffolds

Special consideration needs to be taken when dismantling modular scaffolding as it is possible to remove key components that will eliminate the structural integrity of the components above. Generally, when dismantling modular scaffolding, carpenters will remove components in the reverse order that they were assembled. As these scaffolds can reach great heights, a work platform should be used at each level during disassembly, and a rope should be used to lower components. Keep the components separated by type for storage and discard any damaged pieces.

Tube and Clamp Scaffolds

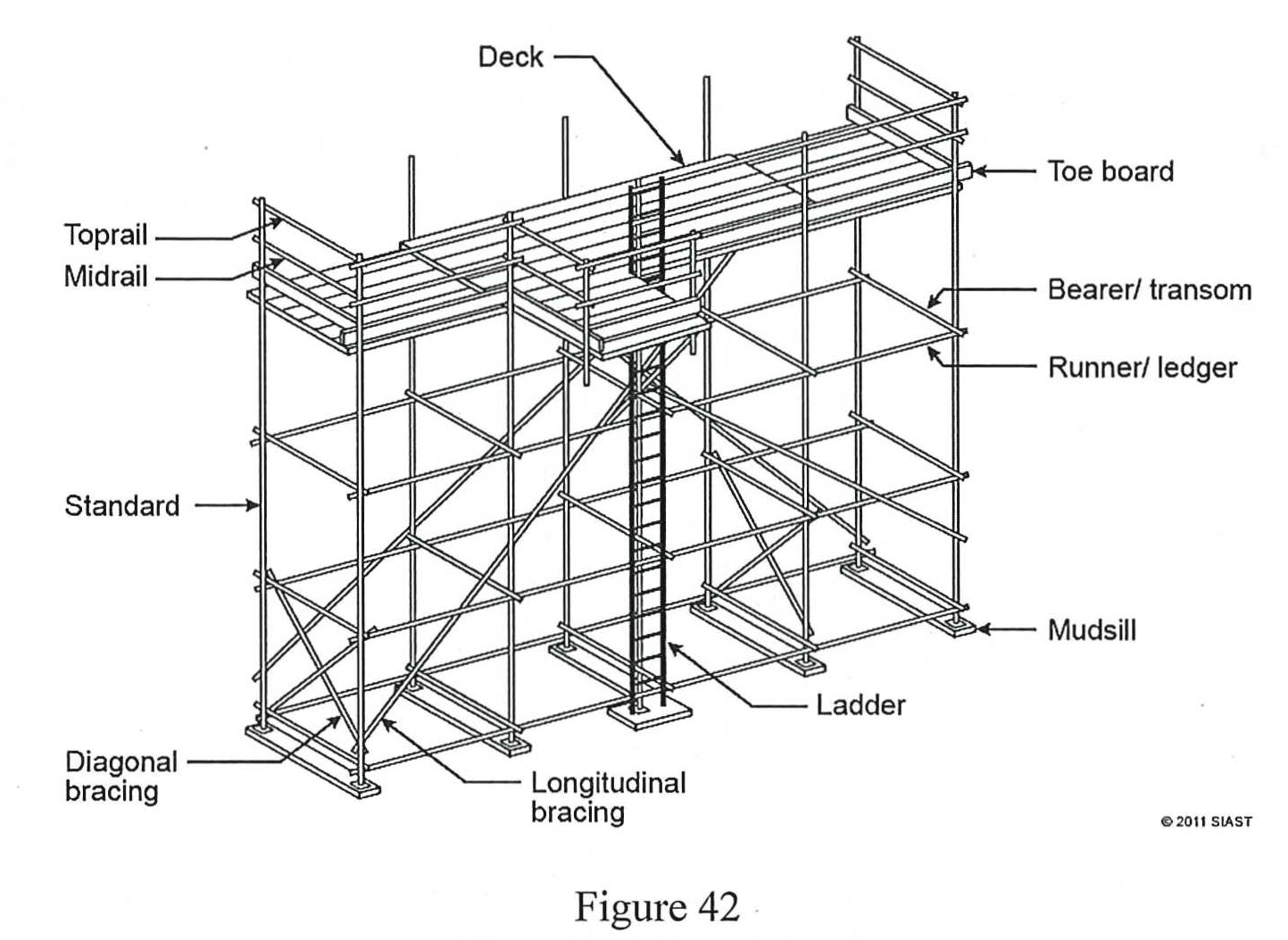

As the name implies, it is essentially tubes of aluminum in various lengths which are attached together using a variety of clamps. It is one of the most versatile types of scaffolding which can be used to provide scaffolding over highly irregular shapes. It can be assembled on uneven ground and requires no special tools to assemble. It is usually designated as a light duty scaffold and requires a skilled worker to assemble. As there are a large number of components, tube and clamp scaffolds take longer times to erect.

The parts of a tube and clamp scaffold can be seen in figure 42 below:

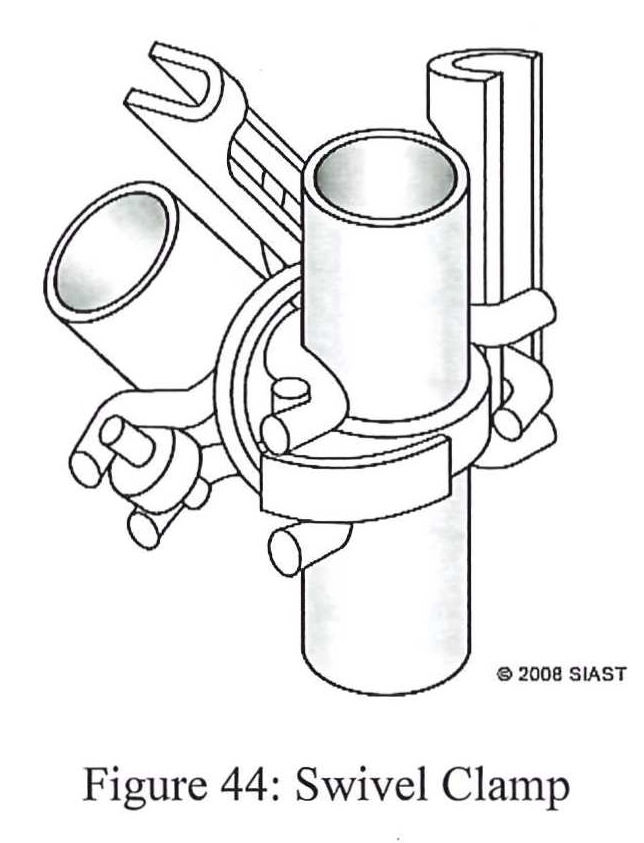

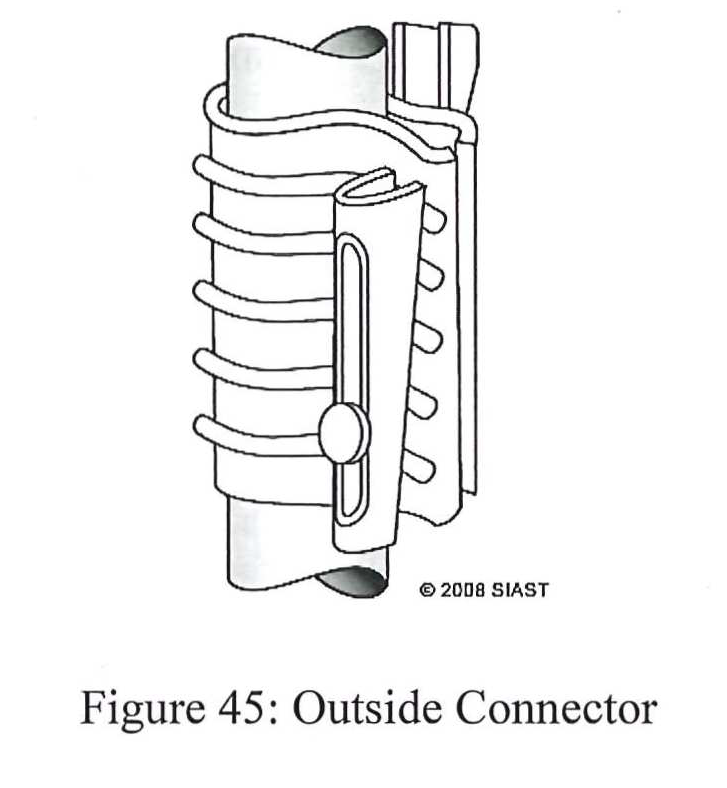

The tubes used come in a variety of lengths from 600 mm – 6000 mm. There are also three different types of clamps that are used:

Review Questions

Use the OHS Regulations to answer the following:

- What are the two main components of a frame scaffold?

- What is required on castors on a steel scaffold?

- What is the minimum dimension required for wooden planks?

- What is used to level scaffolding on uneven terrain?

- What is the name of the component that is used as a horizontal brace?

- What is used to increase the smallest dimension at the base of a steel scaffold?

- Who determines the load rating of a tube and clamp scaffold?

- In tube and clamp scaffolding, are the runners installed inside or outside of the uprights?