Constructs Slab-On-Grade Formwork

Chapter C3 – Constructs Slab-On-Grade Formwork

Key Competencies

The NOA for Carpenter (2013) identifies the required competencies (skills) for the task of constructing slab-on-grade formwork. These are:

- Ensure that substrate is prepared with granular fill and compacted according to specifications and code

- Place void forms for frost protection to allow for frost heave

- Select materials for formwork according to specifications

- Apply products such as polyethylene under the slab to serve as an air, soil, gas (radon) and vapour barrier

- Place formwork and ensure components are plumb, level, straight and square, and accessible for finishing work

- Measure for location and place embeds such as anchor bolts, sleeves and weld plates according to project drawings

- Install required components such as reinforcement steel, keyways, water stops, bulkheads, screed level pegs and miscellaneous inserts

- Apply products such as extruded polystyrene (XPS) under the slab to prevent heat loss

- Create joints such as construction and expansion joints according to project requirements

- Lock corners of forms in order to prevent blowouts and maintain required slab shape such as raft slabs (over size)

- Install bracing such as kickers and threaded rods in order to support formwork in place, and according to specifications

- Ensure that other trades have all below-grade services installed such as sump pit, drains, electrical conduit and hydronic heating

- Inspect assembled formwork for deficiencies such as inadequate bracing, crooked, unleveled formwork and improper grading

- Establish finish elevation according to benchmark and project drawings (NOA, p. 38).

Slab formwork construction uses similar materials as continuous form footings. Slab formwork is used to construct floors, sidewalks and driveways.

Types of slabs

Slabs on grade are common in warm climates where frost penetration is not deep allowing for the floor slab to rest directly on the ground. It is important to prepare the subgrade before placing the concrete for the slab as the ground will directly support the slab to prevent cracking and heaving. The subgrade should be uniformly compacted to the correct elevation to prevent settlement.

Monolithic slabs have the footing and slab combined so that the slab has a thickened edge around the perimeter.

Independent Slabs are slabs that are separate from the foundation usually found in colder climates.

https://en.wikipedia.org/wiki/File:Raft-slab.jpg

Four types of concrete joints for slabs used are:

- Construction joints

- Control joints

- Isolation joints

- Expansion joints

Damp-proofing of slabs can be achieved by placing a sheet of poly between the subgrade and the slab to act as a barrier.

For further information study the following textbooks:

- Carpentry, study the section “Forms for Slabs” Chapter 30

- Principles and Practices of Commercial Construction, study the section on “Construction

- Joints,” Control Joints,” and “Floor Forms”

- Canadian Wood-Frame House Construction, study the sub-section “Slabs-on-Ground”

- National Building National Building Code of Canada, use “Floors-on-Ground”

Review Instruction Sheet (IS) on Brightspace:

FNDT 100 (p. 252 – 261):

- IS 1.2 Concrete Joints

- IS 1.3 Preparing the Sub-Grade for a Slab On-Grade

Review Questions

- The top of a slab-on-grade for a house slab should be at least _____ mm above finished grade.

- What must be done with topsoil that is on the area where the slab will be constructed?

- What type of fill is used under slab on grade?

- Describe a monolithic slab.

- How can the underside of a slab-on-grade be insulated?

- According to the NBC, when can granular fill under a slab be eliminated?

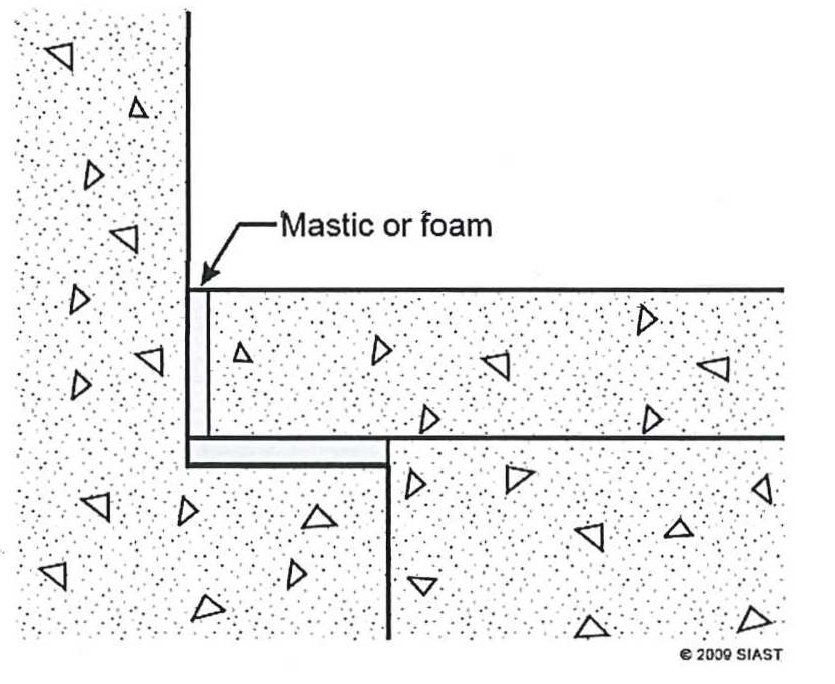

- Shown below is a(n) ___________ joint.

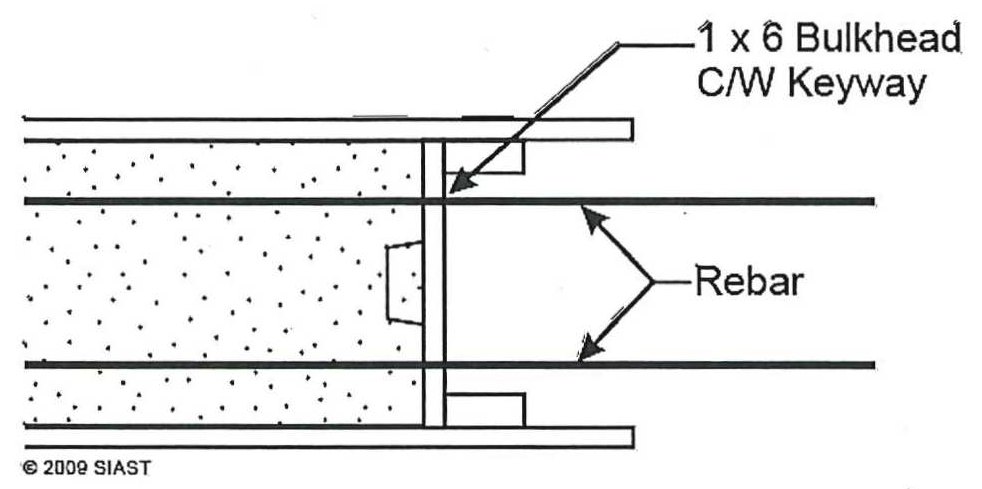

- Shown below is a(n) ___________ joint.

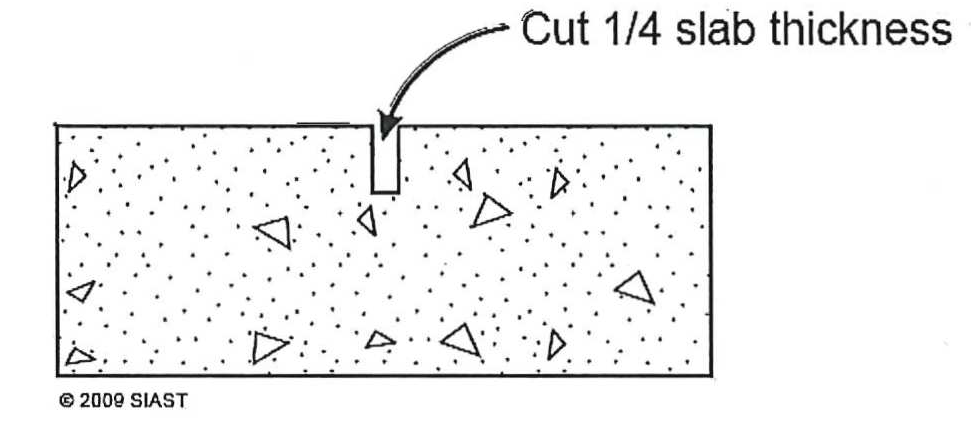

- Shown below is a(n) ___________ joint.