Maintain Stationary Tools

Chapter A2 – Maintains Stationary Tools

Prerequisite Knowledge:

Topic 1 – Identify procedures for Operating Stationary Drills

Drill Press

Drill presses come in a variety of sizes and are capable of drilling at varying speeds. Some are designed to rest on the floor while others are designed to be mounted on a bench top. The drill press consists of five primary parts:

Motor and switch

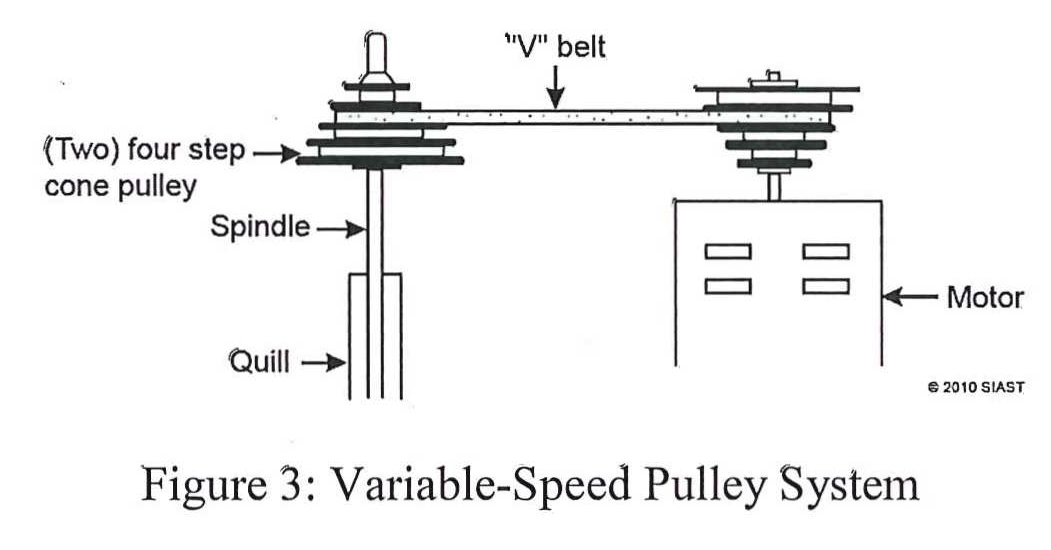

Motor and switch- Variable speed spindle drive system (see figure 3, right)

- Belt tension knob

- Quill

- Depth stop

- Quill lock

- Chuck

- Safety guard

- Feed lever

- Lamp (optional)

The size of drill presses is determined by distance from the center of the chuck to the edge of the column. This determines how wide of material the drill press is capable of drilling into.

Drill Press Operation

Most drill presses contain the variable-speed pulley system which contains two pulleys with four steps, producing four different drilling speeds. Some drill presses have three pulleys to produce six speeds. The speed chosen is dependent on the size of bit and the type of material being drilled. Often the drill press is equipped with a table outlining the appropriate speed depending on material and diameter of hole being drilled. An example of such is seen below:

|

Approximate Operating Speeds for the Drill Press |

||||

|

Hole Size |

Wood |

Aluminum |

Mild Steel |

Hard Steel |

|

Up to 6 mm (1/4”) |

5,600 RPM |

5,600 RPM |

1,200 RPM |

700 RPM |

|

6-12 mm (1/4”-1/2”) |

3,500 RPM |

1,950 RPM |

620 RPM |

620 RPM |

|

12-25 mm (1/2”-1”) |

1,950 RPM |

—- |

—- |

—- |

|

25 mm (1”) and larger |

700 RPM |

—- |

—- |

—- |

|

Hole saw or less |

500 RPM |

—- |

—- |

—- |

Notice how some diameters are left blank. The drill press is not recommended for drilling holes that large in those materials.

Specialty Bits

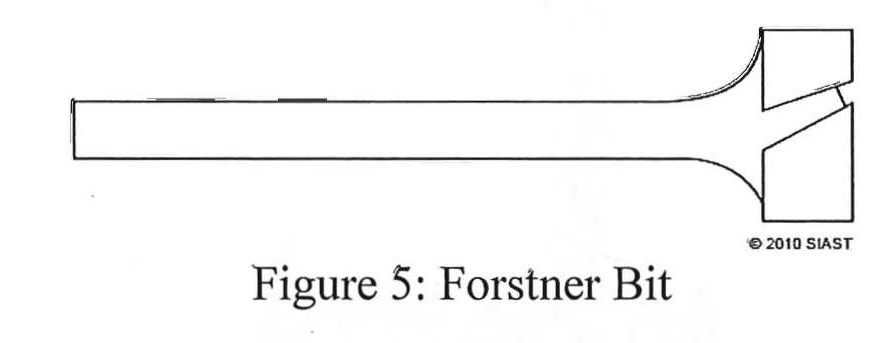

Forstner bits produce clean, accurate cuts. Used for boring into wood or plastic, the point is shallow and it is capable of producing a nearly flat bottom.

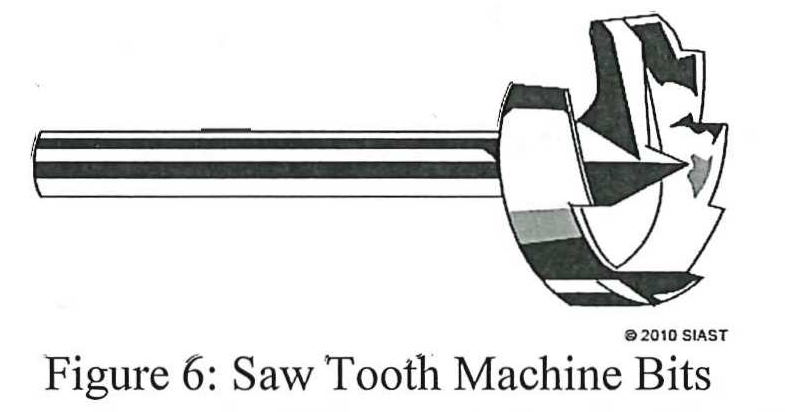

Saw tooth machine bits are similar to forstner bits, with a more aggressive yet precise cut.

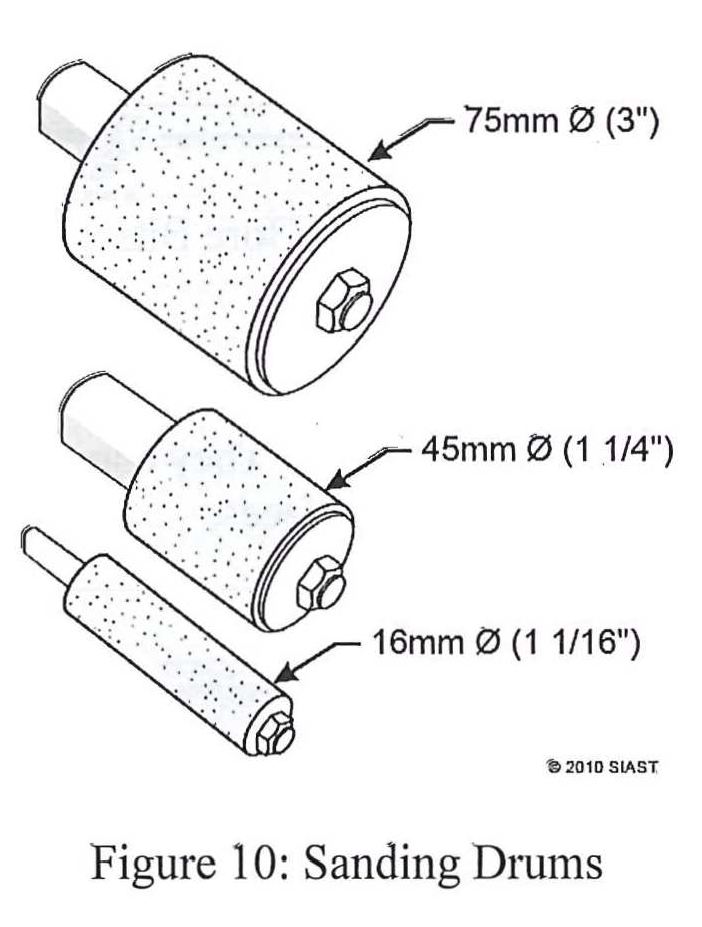

Sanding drums (see figure 10 right) are capable of sanding irregular shapes and into tight curves. While not as effective, they are able to replace spindle sanders in a shop. They are available in a variety of sizes.

Sanding drums (see figure 10 right) are capable of sanding irregular shapes and into tight curves. While not as effective, they are able to replace spindle sanders in a shop. They are available in a variety of sizes.

General Drilling Procedures

Review Questions

- What does the size designation 12” drill press refer to?

- What factors must be considered when choosing the drill speed?

- True or False:

- The softer the material being drilled, the slower the speed

- A four-step, two pulley system can produce 8 different speeds

- The mortising attachment will allow the drill press to drill square or rectangular holes