Operate the Table Saw

Topic 2 – Operate the Table Saw

The Table Saw

The backbone of any woodworking shop and essential for jobsites, the table saw has many uses and is one of the most frequently used tools. The size of the table saw, much like the circular saw and mitre saw, is determined by the diameter of the blade. The most common is 10”, although they can be purchased from 8” all the way up to 16”. The four common variations on its construction are: benchtop saw, jobsite saw, contractor’s saw (see figure 8 right), and cabinet saw. Most construction sites will have a jobsite saw which comes on a portable cart. Cabinet saws are found in most professional woodworking shops.

The backbone of any woodworking shop and essential for jobsites, the table saw has many uses and is one of the most frequently used tools. The size of the table saw, much like the circular saw and mitre saw, is determined by the diameter of the blade. The most common is 10”, although they can be purchased from 8” all the way up to 16”. The four common variations on its construction are: benchtop saw, jobsite saw, contractor’s saw (see figure 8 right), and cabinet saw. Most construction sites will have a jobsite saw which comes on a portable cart. Cabinet saws are found in most professional woodworking shops.

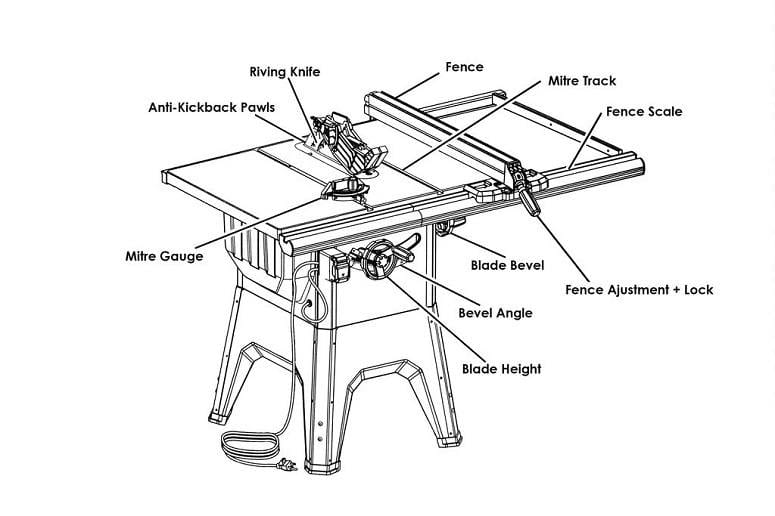

Figure 8 a contractor’s saw and its parts

Parts of a Table Saw

As seen in figure 8, the table saw consists of many parts:

Safety Precautions

The table saw is the most common tool that carpenters are injured on, specifically injuries that cause loss of fingers and limbs. The primary cause of injury is kickback occurring unexpectedly. In order to prevent the material from kicking back erratically, a few precautions should be observed:

Table Saw Capabilities

The table saw is capable of producing a wide variety of cuts. While its primary use is to complete rip cuts, it can also be used for the following:

The last two cuts can be achieved with greater accuracy and efficiency using a dado stack; however, the table saw is capable of completing both with a single blade.

Review Questions

- How is a table saw sized?

- What do you use to make repetitive cross cuts on a table saw?

- List six safety precautions to consider when using a table saw

- How many cuts are necessary to make a rabbet cut using a single blade?

- One

- Two

- Three

- Four

- List four possible cuts that can be made on a table saw

- True or False:

- It is possible to cut compound mitres on a table saw

- It is safe to cut small stock on a table saw

- A push stick and feather board are the same thing

- Ripping stock accurately does not require a straight edge

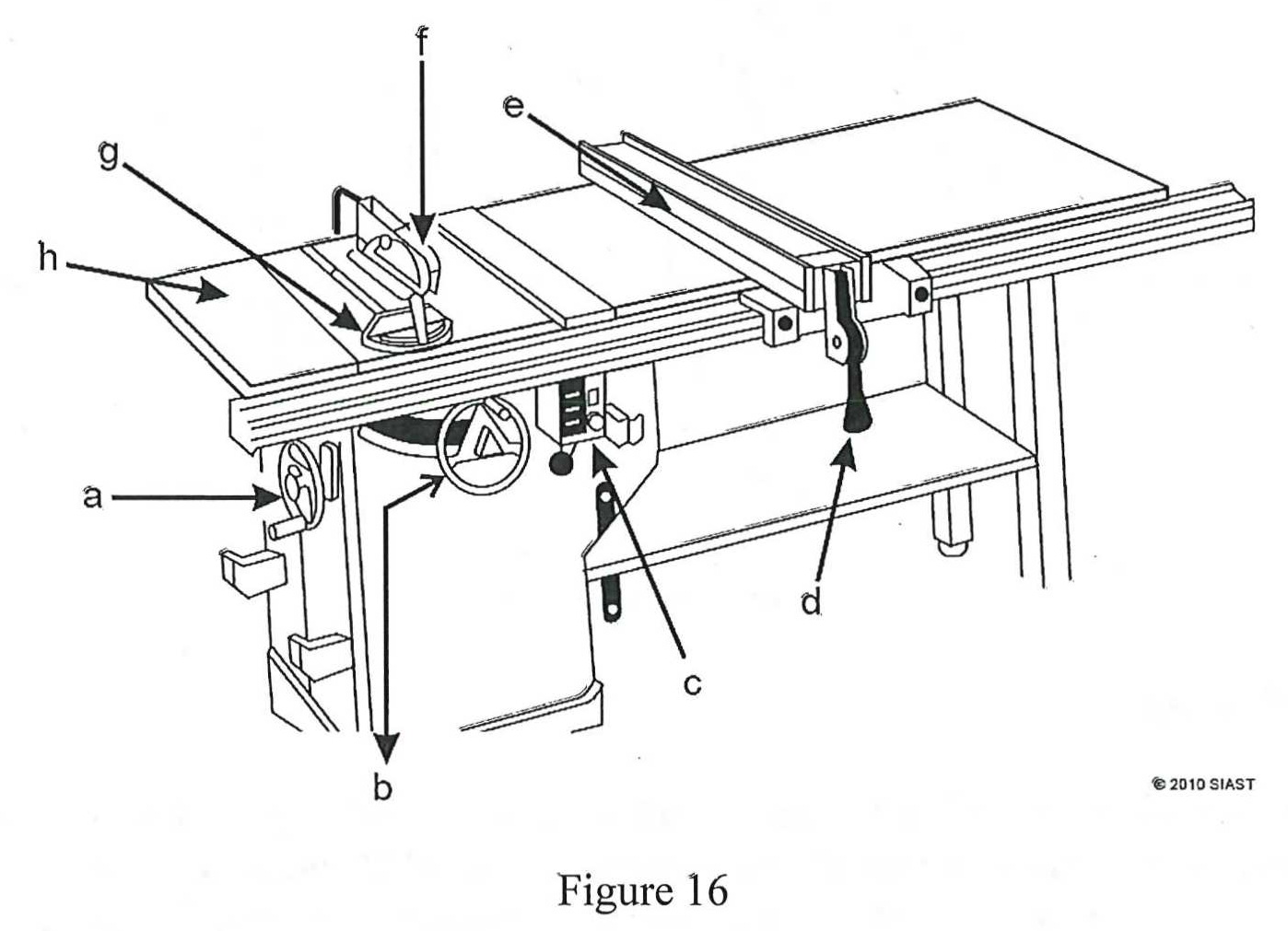

- Name the parts of the table saw in figure 16 below:

Topic 3 – Operate the Band Saw

The Band Saw

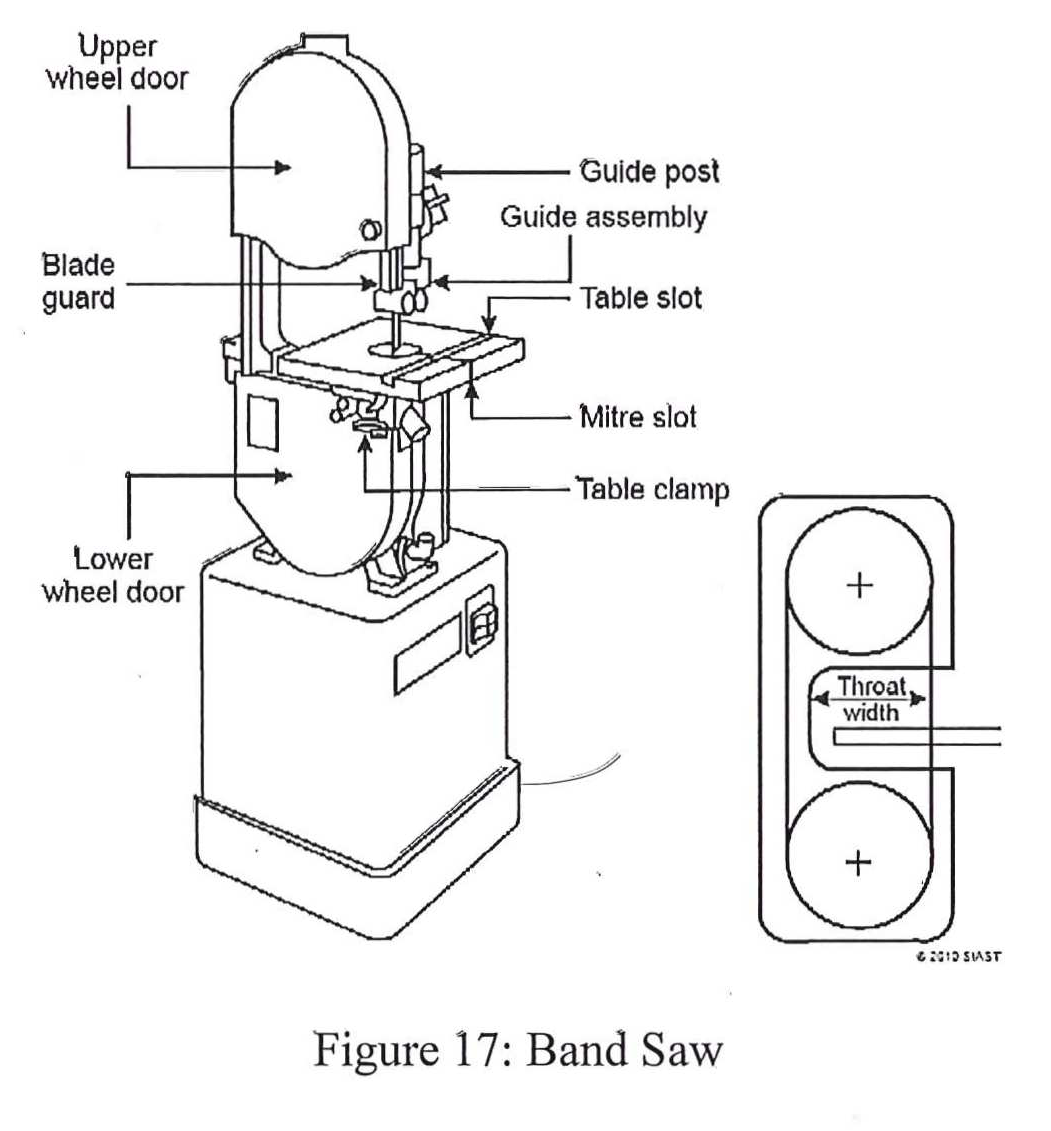

The band saw is used exclusively in milling operations and is a common stationary tool in woodworking shops. It is capable of cutting a variety of materials such as wood, composites, plastic, and light metals. Due to its cutting action, it is capable of cutting through very thick stock and is the only tool that can resaw lumber. It is also capable of cutting curves and radii.

The band saw is used exclusively in milling operations and is a common stationary tool in woodworking shops. It is capable of cutting a variety of materials such as wood, composites, plastic, and light metals. Due to its cutting action, it is capable of cutting through very thick stock and is the only tool that can resaw lumber. It is also capable of cutting curves and radii.

The band saw size is determined by the horizontal distance from the blade to the frame, known as the throat, which varies from 9-20”. The maximum thickness a band saw can cut to is determined by the distance between the table and the upper blade support.

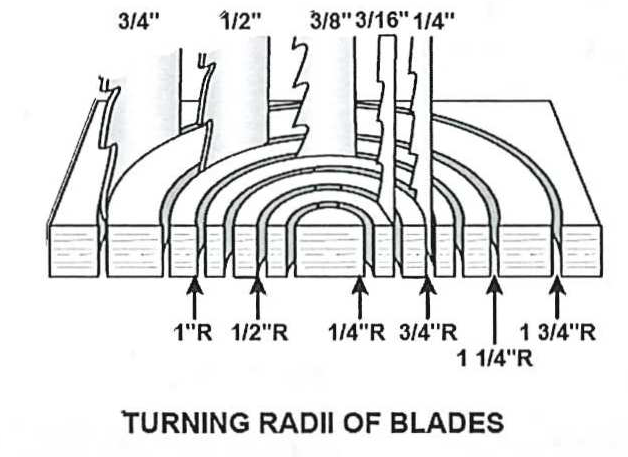

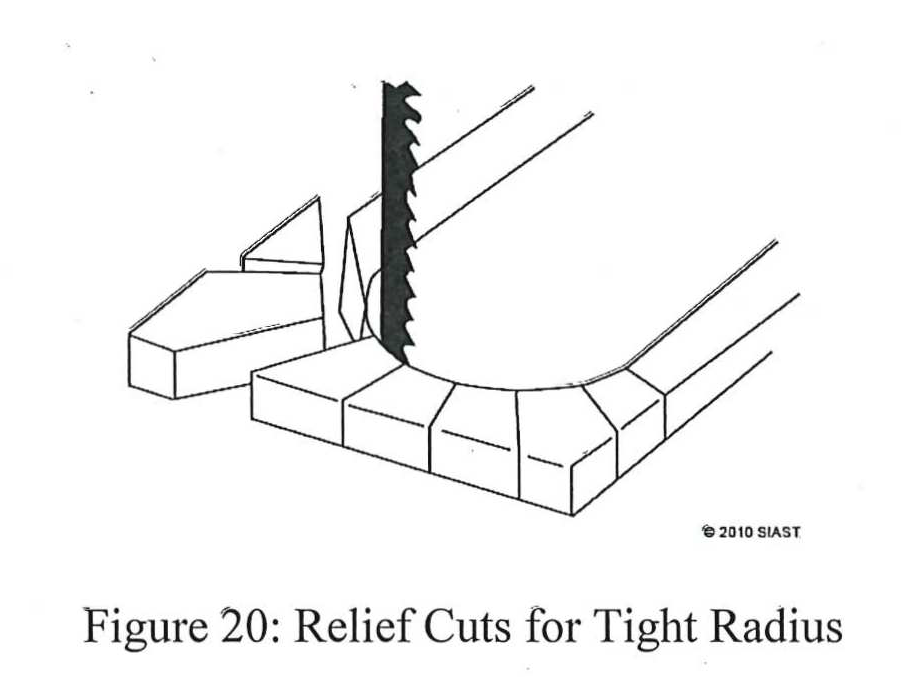

The blade being used is dependent on two factors: the type of material being cut and the radius or how tight of curves will be cut. The type of blade (tooth spacing and set) is determined by the type of material, whereas the blade depth is chosen based on how tight of radius needs to be cut (see figure 9 below). It may also be necessary to make relief cuts for tight radii to prevent the blade from twisting and binding (see figure 20 below).

Figure 9: the depth of the blade effects how tight of radius it can cut.

Blade Alignment and Guide Assemblies

The band saw blade operate on two wheels. The upper wheel, the idler wheel, contains two adjustments. It is raised or lowered to increase or decrease tension on the blade, and it can be tilted  forward and back to align the blade. It is important that the blade is centered on the upper wheel as there is otherwise a risk of it become dislodged during operation. The upper wheel has a slight convex to assist with tracking. The tension is dependent on the blade width; a thinner blade required higher tension to operate safely.

forward and back to align the blade. It is important that the blade is centered on the upper wheel as there is otherwise a risk of it become dislodged during operation. The upper wheel has a slight convex to assist with tracking. The tension is dependent on the blade width; a thinner blade required higher tension to operate safely.

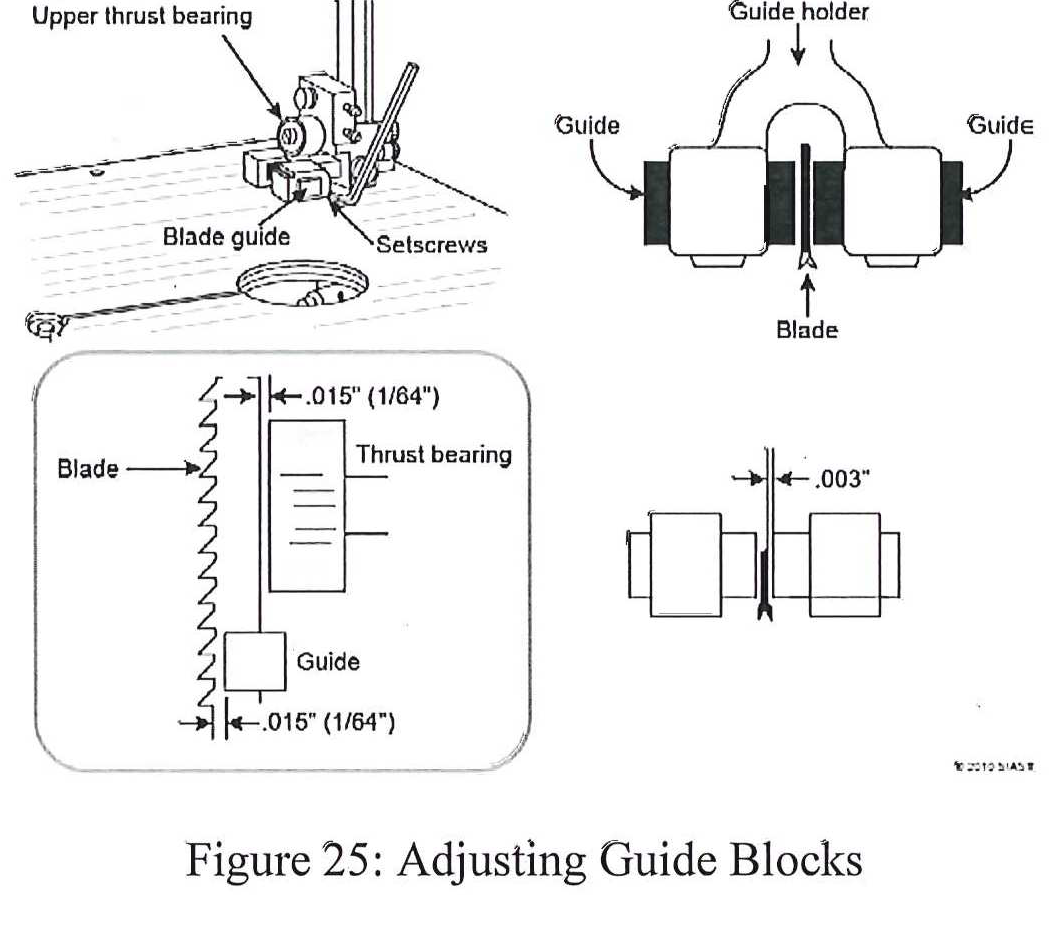

The band saw is equipped with four guide blocks and two thrust bearings. The thrust bearings provide backing when completing a cut and the guide blocks help prevent the blade from twisting when cutting curves. Both the guide blocks and thrust bearings are adjustable for different blade widths and must be calibrated each time a blade is replaced (see figure 25 right).

The upper guide blocks are situated on an adjustable guard which must be raised and lowered for each work piece. To help prevent injury and maximize the effectiveness of the upper guide blocks, a clearance of 6-12 mm (1/4 – 1/2″) is recommended between the guard and the work piece.

Band Saw Safety

The band saw is considered one of the safest saws to operate, however there are a number of practices that should be followed to ensure safe operation:

Review Questions

- What should be done prior to putting the blade under full tension?

- What PPE must be worn when operating a band saw?

- How much clearance should be between the workpiece and guard?

- When placed under cutting load, the blade contacts the ________.

- The wheels on a band saw have a slight ______ to help tracking.

- Groove

- Concave

- Crown

- Tread

- How many guide blocks are there on a band saw?

- What two factors the choice of blade on a band saw?

- If you were making two cuts that meet on a band saw, which should be cut first, the longer or shorter one? Why?

- Describe resawing

- In what two ways can the upper wheel be adjusted?