Operate the Jointer and Planer

Topic 4 – Operate the Jointer and Planer

The Power Jointer

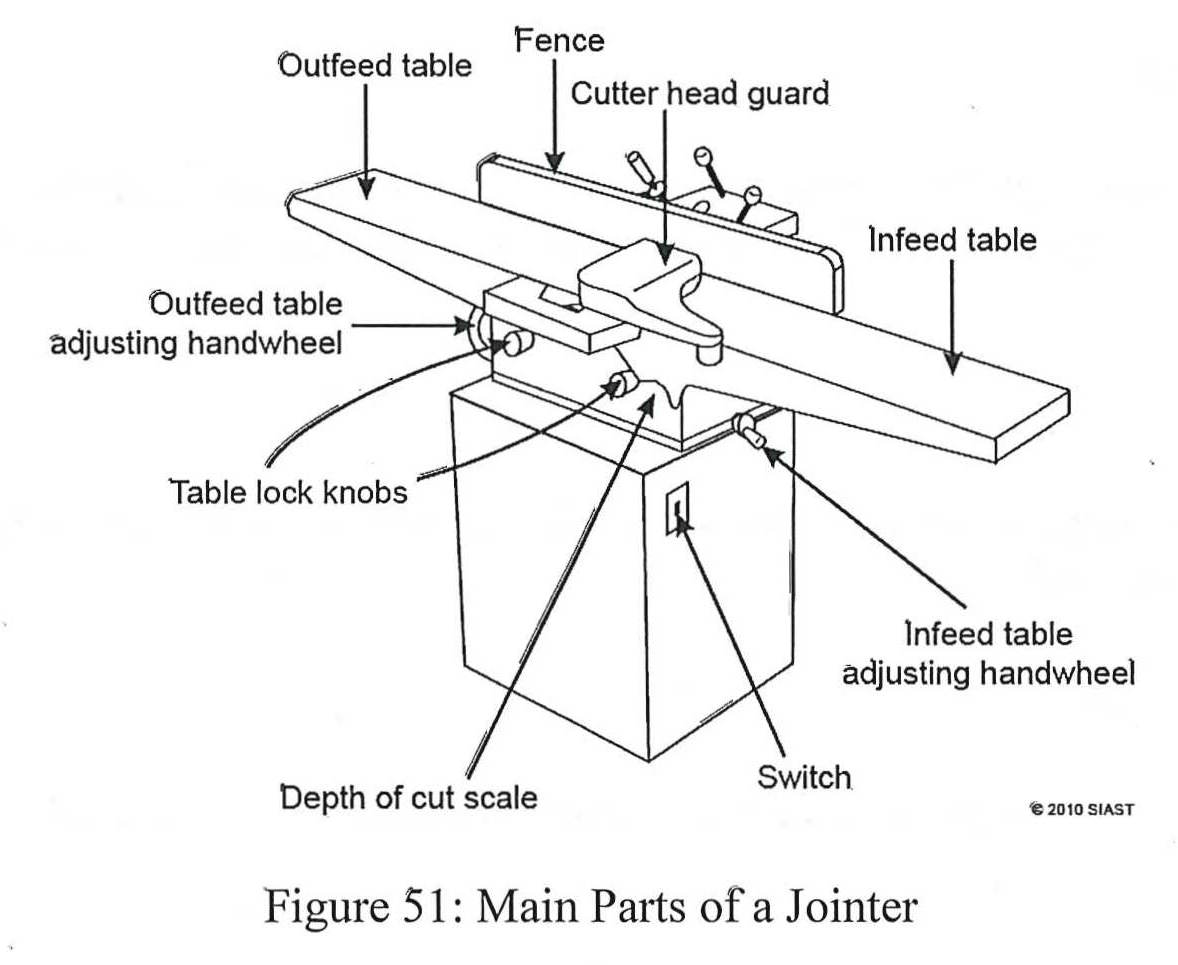

The Jointers primary purpose is to plane edges and faces of stock. With an infeed and outfeed table, it has the ability to produce flat faces, and square, true edges. It can also be used (less commonly) to produce rabbets, bevels, and chamfers. Jointers are sized according to their blade width, which is commonly 6” or 8”.

The Jointers primary purpose is to plane edges and faces of stock. With an infeed and outfeed table, it has the ability to produce flat faces, and square, true edges. It can also be used (less commonly) to produce rabbets, bevels, and chamfers. Jointers are sized according to their blade width, which is commonly 6” or 8”.

The depth of cut is dependent on application and is adjusted by raising and lowering the infeed table. The cutter head is aligned with the outfeed table and remains stationary once it has been properly set up. As the cutterhead remains stationary, the fence must be tilted to produce a bevel or chamfer and moved inwards to produce a rabbet.

When working with rough stock lumber, the jointer is usually the first tool that it is brought to. While the planer is used to produce smooth surfaces, any twists within the board are likely to remain. The jointer is designed to cut out many defects in the lumber including crooks, bows, and twists. After a flat face, and square edge are achieved on the jointer, the workpiece can be planed on the planer and cut to width on the table saw.

Jointer Safety

Power Thickness Planer

The thickness planer is used to machine lumber to specific thicknesses and product two flat, parallel faces. While the depth of stock accepted varies from planer to planer, the size of the planer is determined by the width of the cutter head.

Parts of the Planer

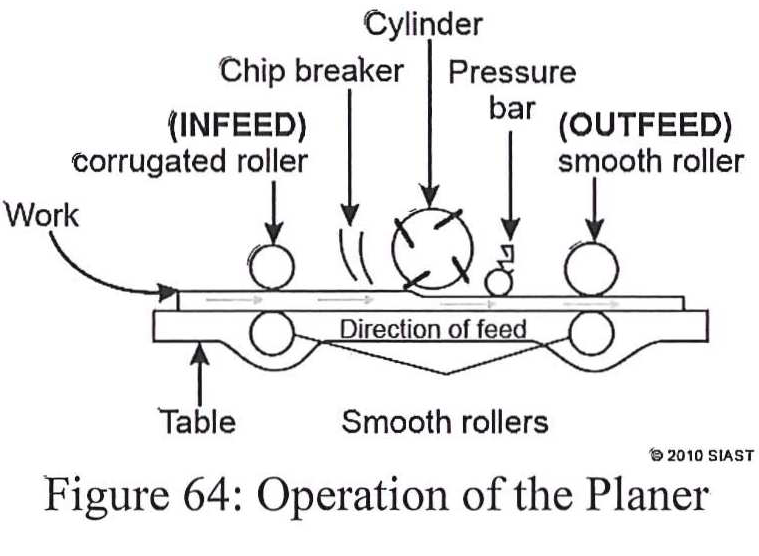

The planer consists of a table which, depending on the design, may be stationary or raised and lowered in relation to the motor (in some planers, the motor is adjusted for height). As the work piece is entered into the machine, an infeed roller automatically pulls the material in past the cutter head at a consistent speed. Behind the cutter head is an outfeed roller and pressure bar which helps ensure that the piece remains flat and produces a consistent cut as it is completed. Much like the jointer outfeed table, the outfeed roller is set to the same height at the cutter head and should not vary from its position (see figure 64 right).

The planer consists of a table which, depending on the design, may be stationary or raised and lowered in relation to the motor (in some planers, the motor is adjusted for height). As the work piece is entered into the machine, an infeed roller automatically pulls the material in past the cutter head at a consistent speed. Behind the cutter head is an outfeed roller and pressure bar which helps ensure that the piece remains flat and produces a consistent cut as it is completed. Much like the jointer outfeed table, the outfeed roller is set to the same height at the cutter head and should not vary from its position (see figure 64 right).

Operating the Planer