Eye and Respiratory Protection

Topic 2 – Eye and Respiratory Protection

Types of Eye Protection

For most worksites, eye protection is required at all times. Debris from cutting material, drilling, projectiles from hammering, dusty conditions, and many other scenarios pose a significant risk to our eyes. There is three primary types of PPE that is worn to protect our eyes:

Sometimes carpenters may also be working in the vicinity of a welder. Of course, using a welding helmet is the most effective. However, if this is not practical, a welding screen may be acceptable.

Respiratory Hazards

The most common respiratory hazards are when cutting materials. Whenever a material is cut, there is going to be the production of fumes and/or dust suspended in the air. Concrete, steel, and wood all produce respiratory hazards when they are cut and must be mitigated if possible. Carpenters are often asked to work with chemicals that produce vapours which can pose respiratory hazards of their own. A worker should always be aware of what they are working with and how to reduce the respiratory hazards that are associated with that product. Much like noise, the source of respiratory hazards should be reduced or eliminated first, if possible. There are a number of ways this can be accomplished:

Respiratory Protection

Respiratory protections comes in two main styles: dust masks and respirators. All types of respiratory protection rely on filtering out the airborne particles and vapours. The proper PPE must be worn for each task.

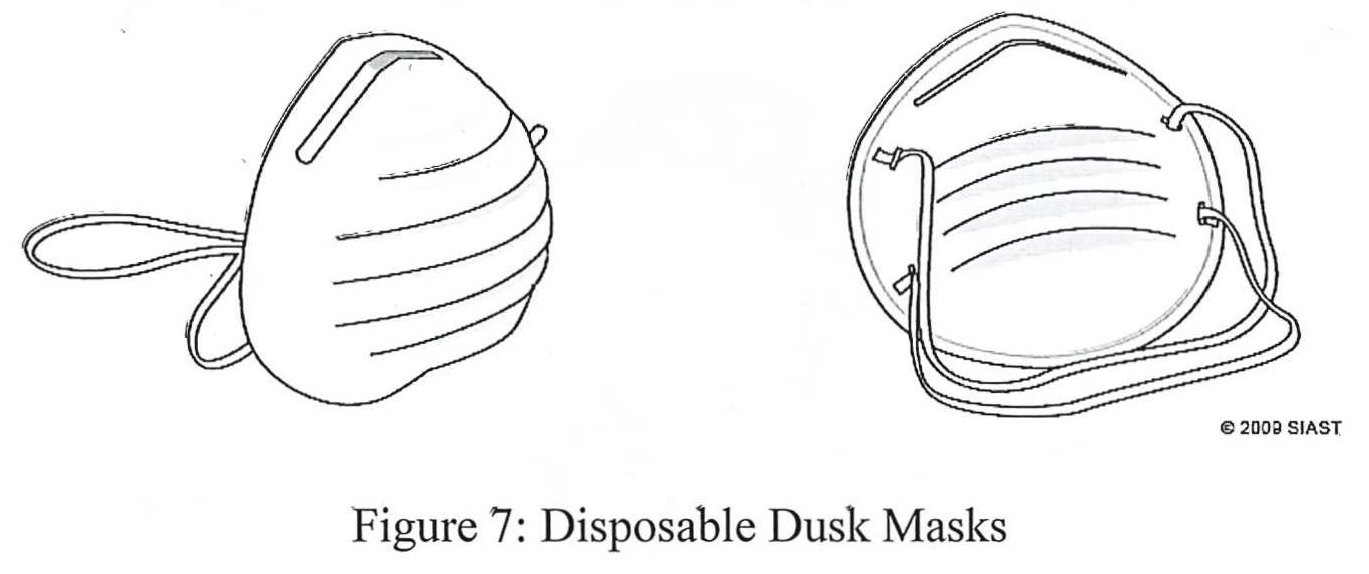

Dust masks are a disposable PPE that is worn to protect the user against airborne particles. They are not considered to be respirators and do not protect the wearer against inhaling vapours. They are suitable for filtering out sawdust and are a common respiratory protection in a woodworking shop (pictured below).

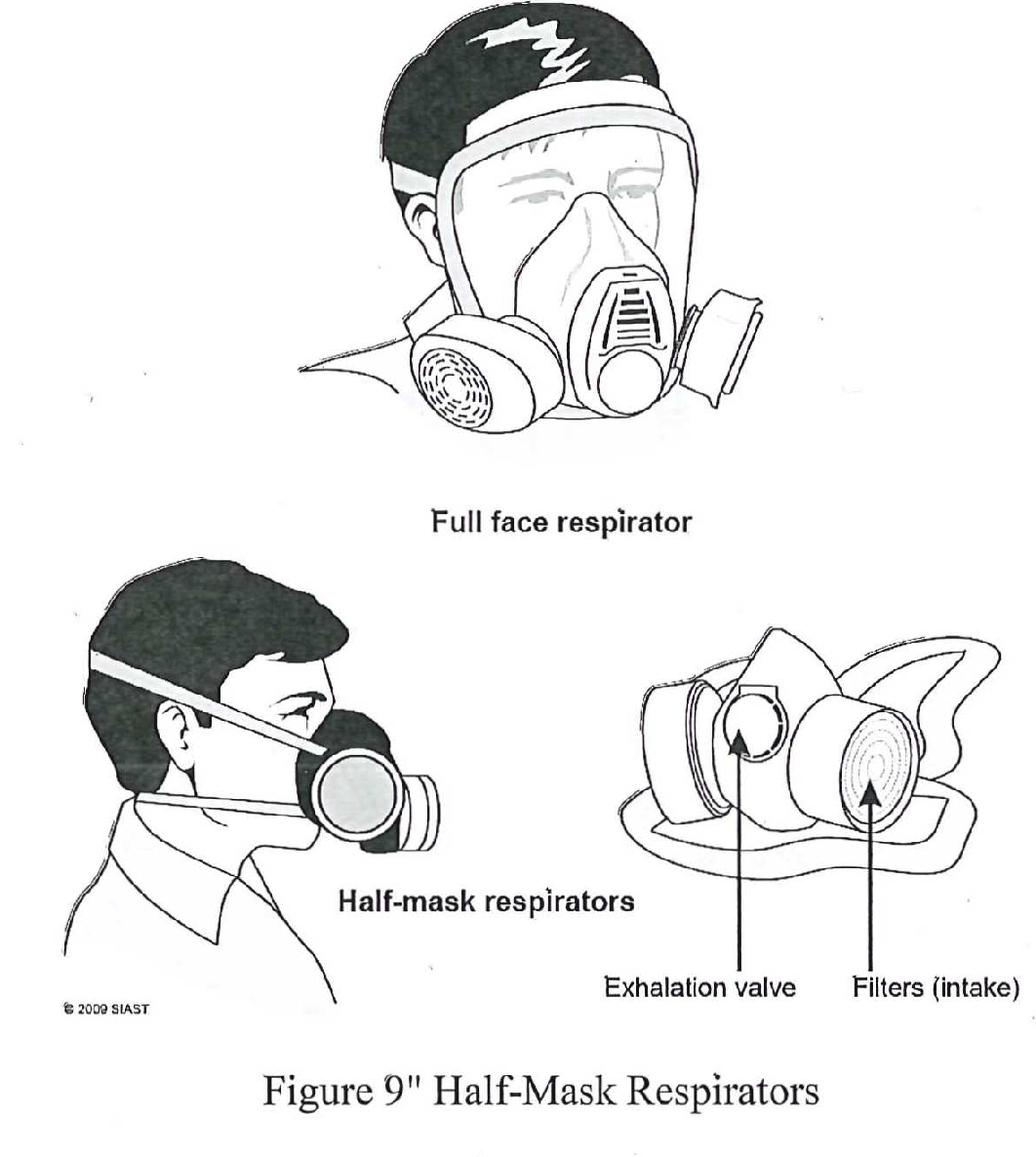

Respirators function under the same principles as dust masks but are more effective at filtering out both particles and vapours as they fit tightly to the user’s face. They come in two different styles: full face respirator and half-mask respirator (pictured right).

Respirators function under the same principles as dust masks but are more effective at filtering out both particles and vapours as they fit tightly to the user’s face. They come in two different styles: full face respirator and half-mask respirator (pictured right).

The ability for the respirator is determined by the filter that is used. They come in three basic types:

Always make sure you are using the right filter. Using the wrong filter can give the user a false sense of protection. The type of filter required for a job can be determined by an air test, type of work that needs to be don, and the amount of time you need to wear it.

In order for respirators to work, they must be tight fitting to your face. A fit test should be completed each time you wear the respirator. The respirator should be inspected prior to each use and maintained to ensure it stays in working order. Check for worn straps, holes and tears, and broken or loose connectors. Make sure the respirator is clean and dry before storing for later use.

Review Questions

- Name three types of eye protection.

- Who is responsible for supplying eye protection on a jobsite?

- The type of respirator required depends on three things, what are they?

- Is training required to use a respirator?

- Name three ways to reduce dust hazards in a wood working shop.

Topic 3 – Head, Hands, and Feet PPE

Head Protection

Hard hats are the best protection for you head against falling objects and impacts. It can also protect you from electric shock. The hard hat is composed of an outer shell and inner suspension that allows some room for shock absorption which is attached at four or six points. The hard hat comes in two different styles: peaked and full brim (pictured below). The peak and brim provide a lip for objects to ricochet off and deflect them away from the users face and torso.

Hardhats come in different classifications:

Safety Footwear

Safety footwear comes in many classifications with different features. All safety footwear needs to be marked and approved by the CSA. Markings on footwear indicate the type of protection offered. The three most common for construction workers are indicated below:

|

Marking |

Type of Protection |

|

|

Green triangle; indicates sole puncture protection with a grade 1 protective toe. |

|

|

Yellow triangle; indicates sole puncture protection and grade 2 protective toe. |

|

|

White rectangle with orange Greek letter omega. Made with soles that protect against electric shock. |

Most construction workers will wear footwear than contains a green triangle and white rectangle for the most effective protection against sole punctures, crushing, and electrical shock. Boots are also made with either 6” or 8” heels which provides ankle protection and support.

Hand Protection

Many tasks that are required of carpenters pose a risk to hand injury. Gloves are recommended or required for many tasks and should be chosen appropriately to protect against cuts, scrapes, burns, splinters, and cold weather.

Other Safety Considerations

- Wear slip resistant footwear

- Keep walkways clear of clutter and slippery conditions such as ice and grease

- Grasp vibrating tools lightly, let the tool do the work

- Wear gloves when using vibrating tools

- Take breaks when discomfort arises

- Do not wear overly loose or torn clothing as it can be caught in machinery and tools

- Wear short sleeved shirts where possible

- Keep tools in aprons, not in your pockets

- Do not wear jewelry while working