Maintains Hand, Power and Pneumatic Tools

Chapter A1 – Maintains hand, Power, and Pneumatic Tools

Prerequisite Knowledge:

- The ability to convert between the two is an asset

- Pocket tape, steel tape

Topic 1– Layout and Testing Tools

Steel Square

The steel or “framing” square has many uses. With graduations on both parts, named the “tongue” and the “body”, it can be used in a variety of situations. Steel squares come in both metric and imperial graduations. Its most obvious use is marking square lines, especially when marking wall plates as the tongue is long enough (12”) to span 2 – 2×6 plates. More importantly, the steel square is essential in laying out and marking all components of a roofing system as well as stair stringers.

***Of the many uses above; can you think of any that might be missing? List what you can think of:

*** List at least two different squares and their uses/limitations:

Protractor and Bevel

Protractor and Bevel

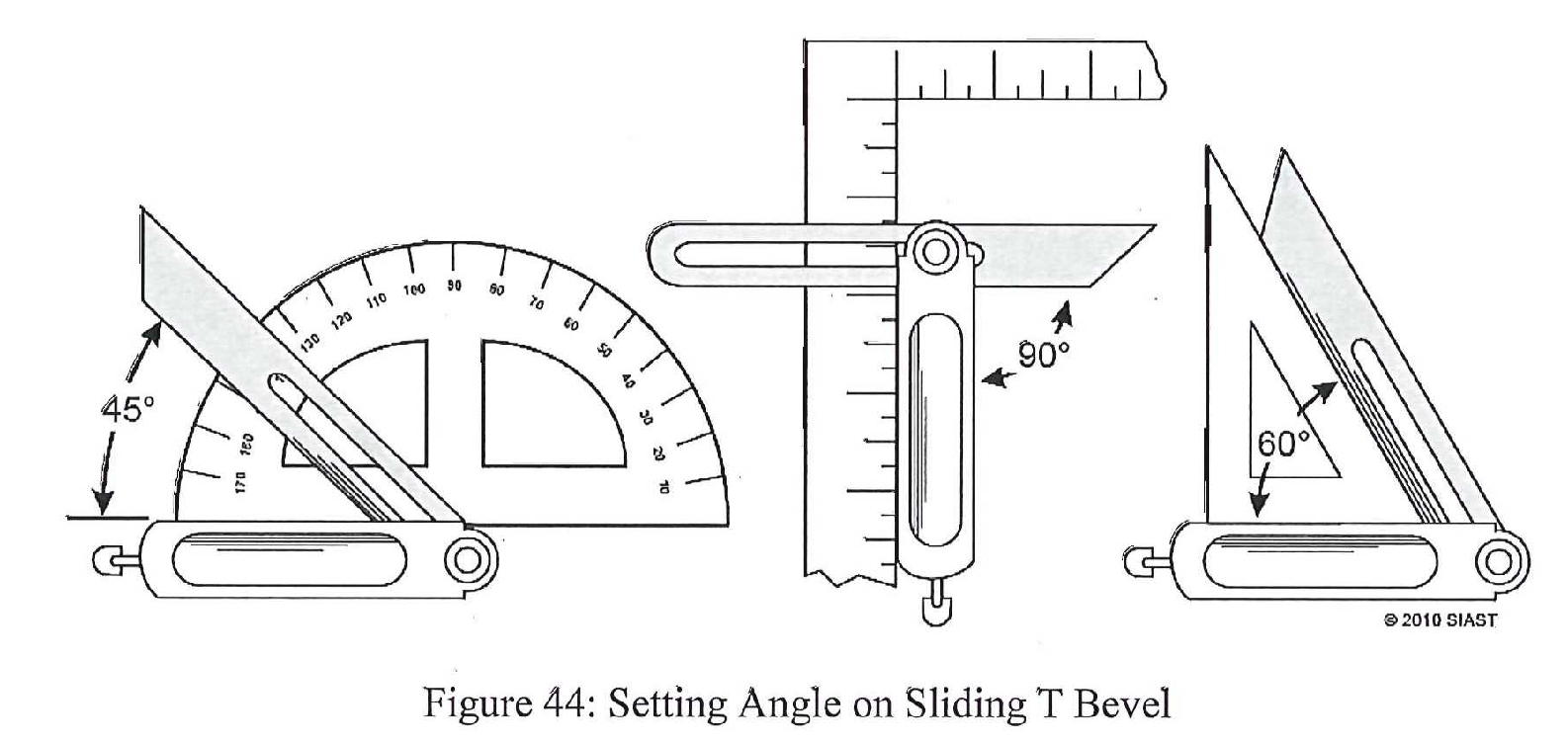

The protractor is useful for finding specific angles. It is calibrated to 180° and can find and measure any angle inside. It is often used in conjunction with a bevel, which is s tool that is strictly used to replicate and transfer angles, not measure them as the protractor does (see figure 44 right).

Pencil Compass

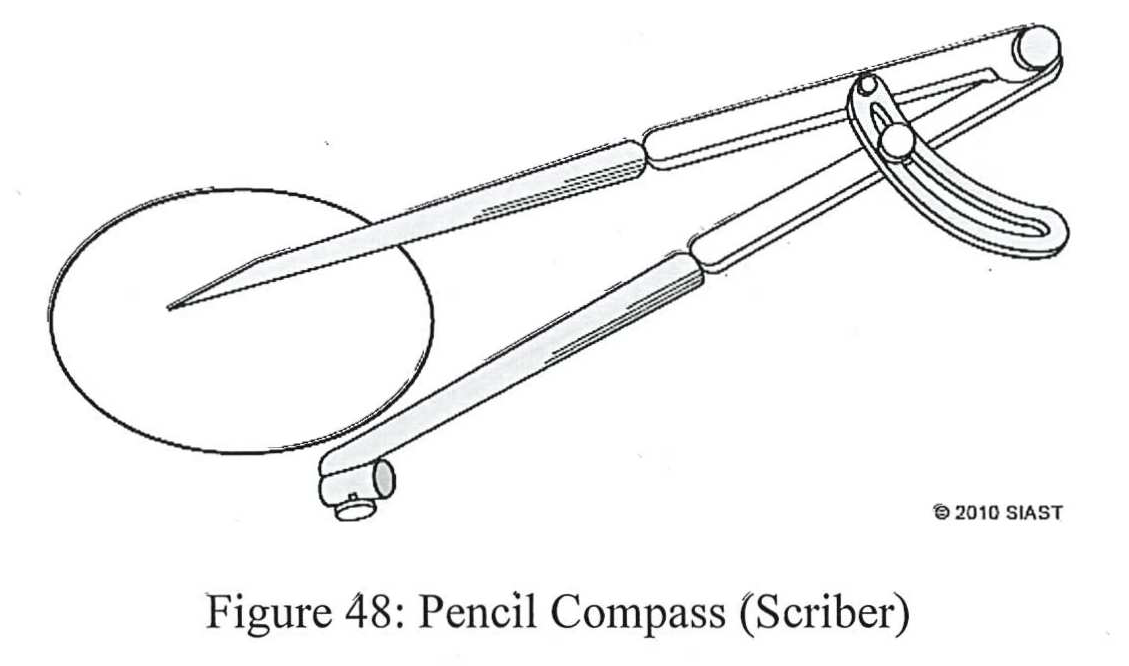

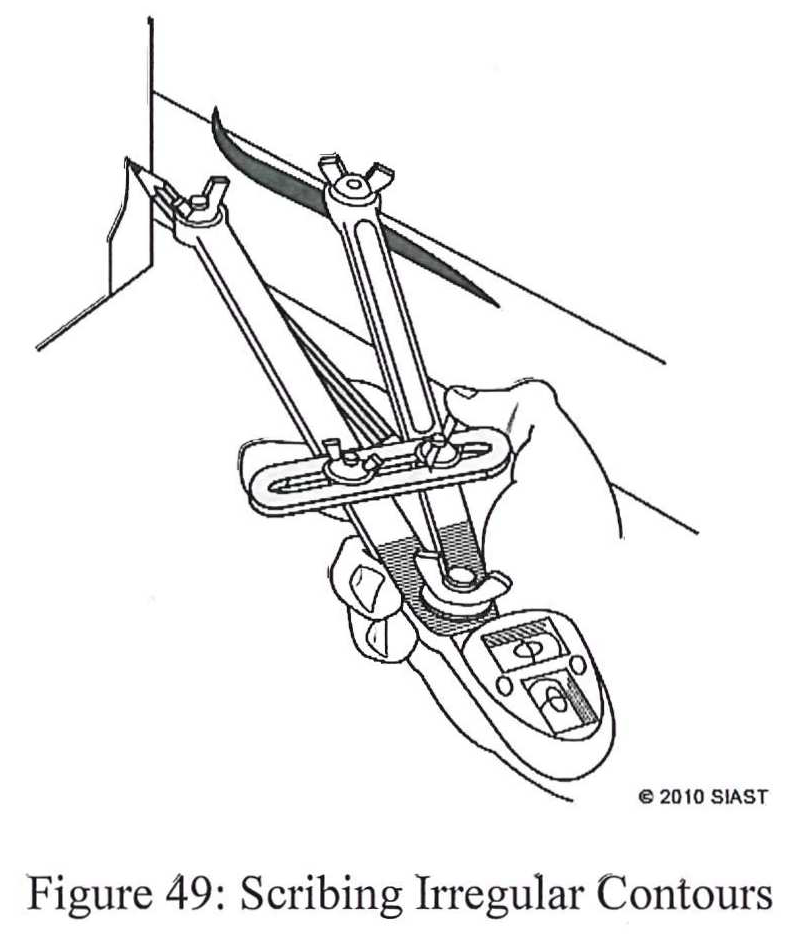

The pencil compass (also known as the scriber) is most commonly used for scribing circles or arcs (see figure 48). It can be precisely adjusted but required a measuring tool to establish a radius. For carpenters, it is often used to scribe irregular shapes and contours to achieve a coped joint (see figure 49 below).

The pencil compass (also known as the scriber) is most commonly used for scribing circles or arcs (see figure 48). It can be precisely adjusted but required a measuring tool to establish a radius. For carpenters, it is often used to scribe irregular shapes and contours to achieve a coped joint (see figure 49 below).

Trammel Points

Trammel Points

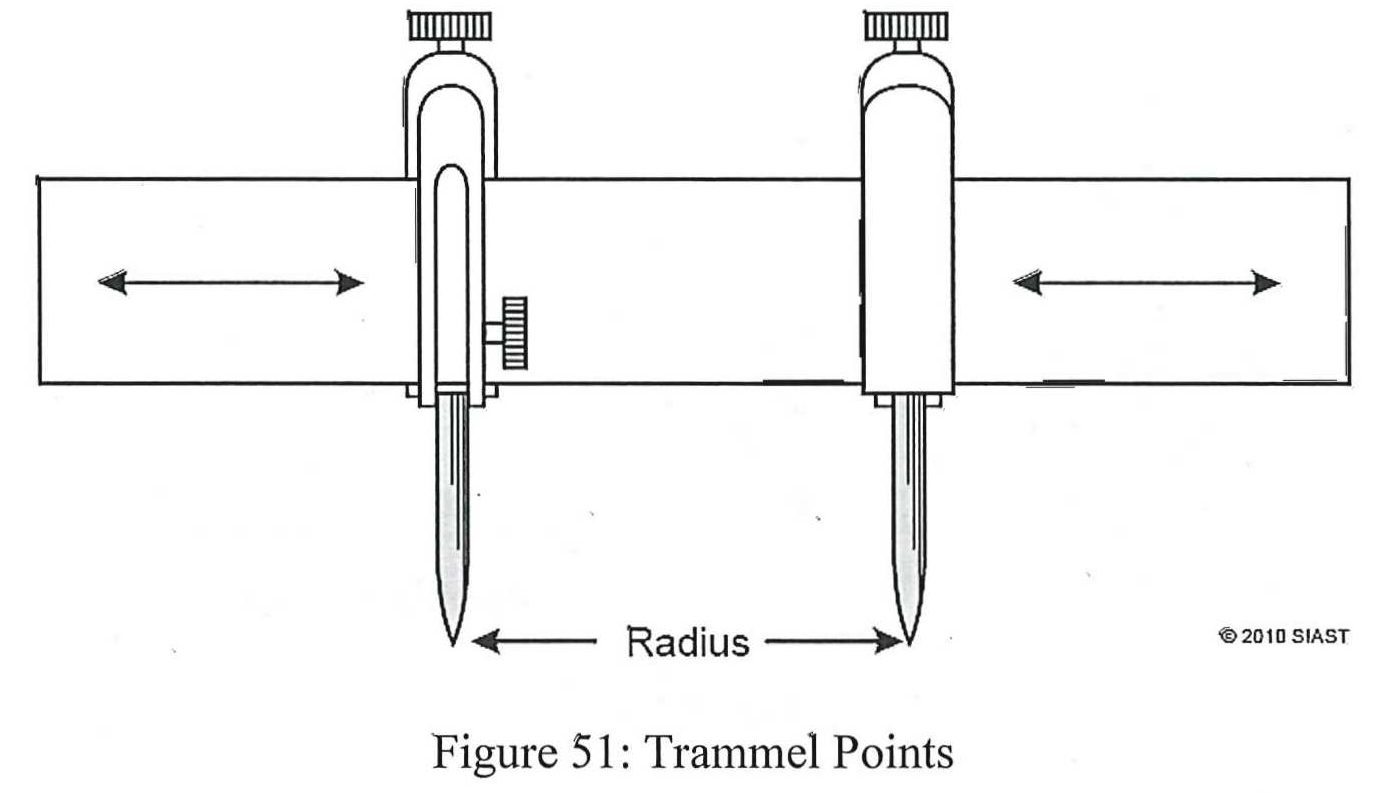

Trammels are a set of points set on a straight, rigid board that can be adjusted to different lengths. Similar to the compass, the points are set to the radius of the desired arc or circle. The length of the radius is only limited by the length of the board. It is capable of producing much larger radii than the compass.

Hand Levels

Hand Levels

These levels can be made with either wood, metal, or composite materials. They function on the principle that air is lighter than water. The vial used contains a fluid (usually alcohol) that will not freeze. Most levels can be used to test for level or plumb, with longer levels containing multiple vials producing greater accuracy.

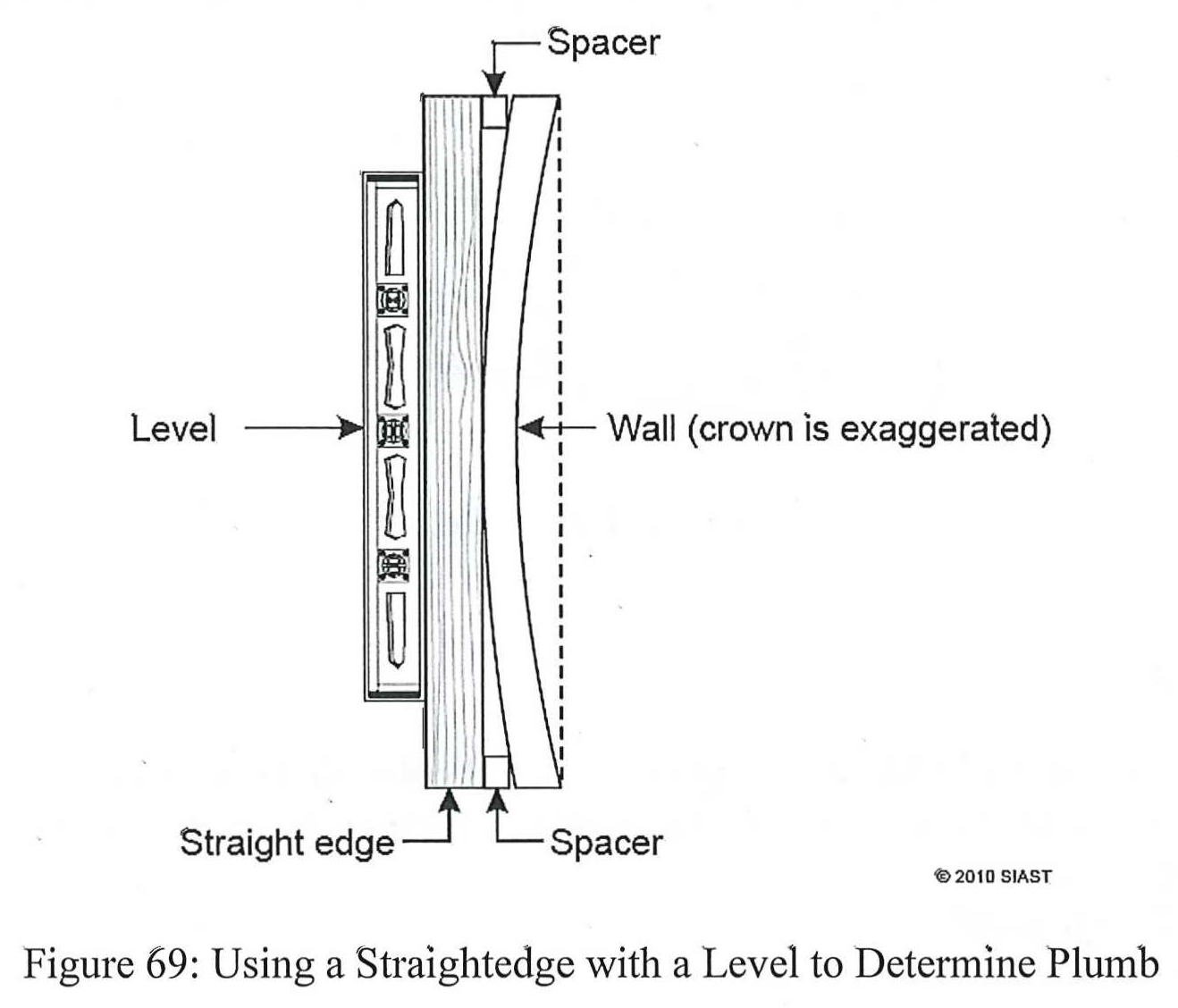

A common use of the hand level is to check walls for plumb. Often, studs contain a pronounced crook. In order to prevent the level from rocking on the crown, a straight edge must be used (see figure 69 right).

Plumb Bob

This tool is attached to a stringline and then hung down from or to a point to check for plumb. It is limited to a single point and can easily be affected by wind or unsteady hands. Some plumb bobs can be filled with mercury to achieve a greater weight/volume.

Water Level

Water Level

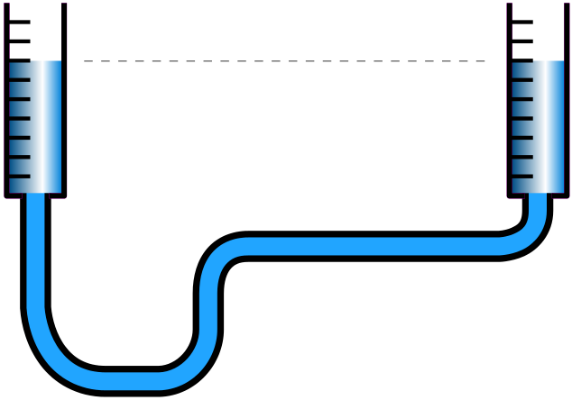

An extremely accurate device which can be used to transfer elevations over long distances. Two vials are attached to hose which is filled with water. As long as the two ends of the hose are left open, the water level at both ends will remain at the same elevation.

Image By Bd, CC BY-SA 3.0, https://commons.wikimedia.org/w/index.php?curid=46342405

Review Questions – 1.01.1

- Determine the best tool that would be used to perform the following operations:

- Layout a curve with a radius of 45 mm

- Layout a 45° angle on a 300 mm wide board

- Transfer a 55° angle from a protractor to a board

- Scribe a board to fit an irregular contour

- Mark a straight line 4 meters long

- Can you set a bevel to 35° without using another tool? If not, what other tool is needed?

- Describe/define the following terms:

- Level

- Plumb

- Describe how to mark a 45° angle on a piece of lumber using the steel/framing square.

- If extremely accurate measurements are required, what must be considered?

- List two precautions a carpenter should take in caring for a steel tape.

- What is a marking gauge used for?

- What type of square can be used with a pencil in place of a marking gauge?

- A change in elevation over a distance can be accurately measured with a _______ level?

Topic 2 – Identify and Use Hand Saws

Crosscut Saw and Rip Saw

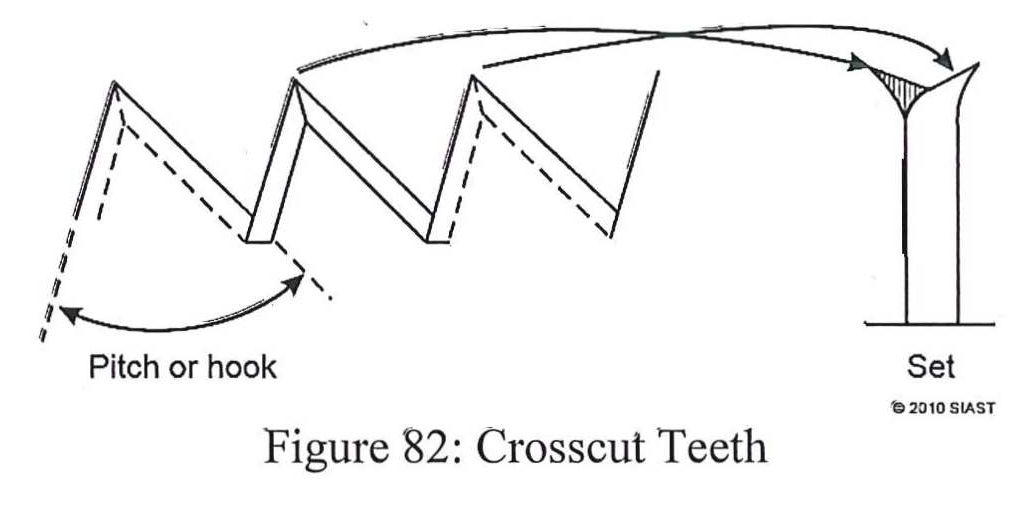

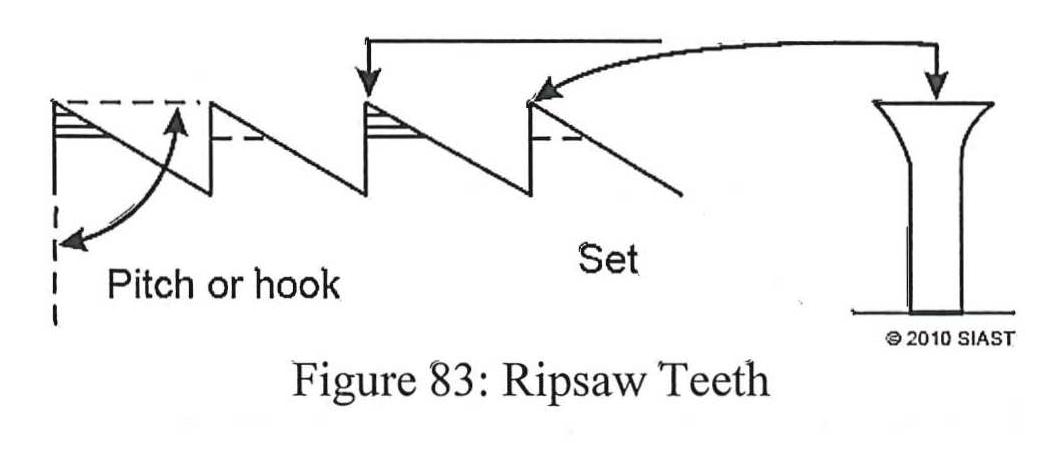

These two hand saws are used for the two most common cuts a carpenter will make. They primarily differ in their “set” and shape of teeth. Both saws are designed to have a greater blade width where the saw enters the material to allow clearance as the blade makes its way through the board.

When using the crosscut saw, it is best to start at a 45° angle to the stock and allow the shorter side of the stock to sit over the supports. An angle of 60° should be maintained when make a rip cut. Sometimes inserting a wedge into the kerf may be necessary if the board bows into itself and binds the saw.

(Above) A close up view of the crosscut and rip saw teeth. Notice how the different shapes and alternating teeth produce specific cutting action.

***Describe the two different types of cuts:

Cross Cut: ______________________________________________________________________

Rip Cut: ________________________________________________________________________

*** Why do you think the two saws are designed differently? What factors or considerations must be made when producing a desirable cut?

__________________________________________________________________________________________________________________________________________________________________________

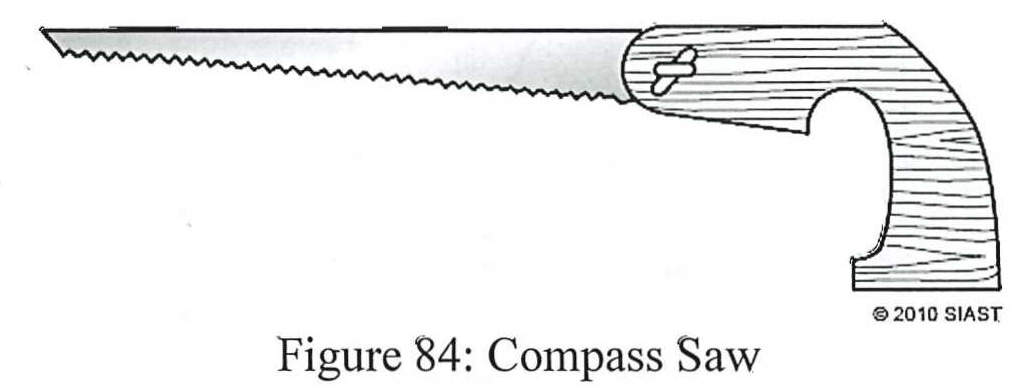

Compass and Keyhole Saws

The compass saw has thin, tapered blades which allows it to make curved or irregular shaped cuts. Because the blade is tapered, the wider portion can be used to produce straighter cuts while the narrower end can be used for curves and bends. The teeth are set to produce acceptable cuts both with and across the grain.

The compass saw has thin, tapered blades which allows it to make curved or irregular shaped cuts. Because the blade is tapered, the wider portion can be used to produce straighter cuts while the narrower end can be used for curves and bends. The teeth are set to produce acceptable cuts both with and across the grain.

The keyhole saw is similar to the compass saw but contains a narrower blade giving it the ability to produce tighter curves. The teeth are also shorter and finer.

Coping Saw

The coping saw is used to cut very fine irregular shapes, such as when producing coped joints in moulding. The thin blade allows it to follow tight turns and sharp angles within a piece. Because the blade is so thin, it is only used in finish applications and one must be careful to not force the cut as it can easily break.

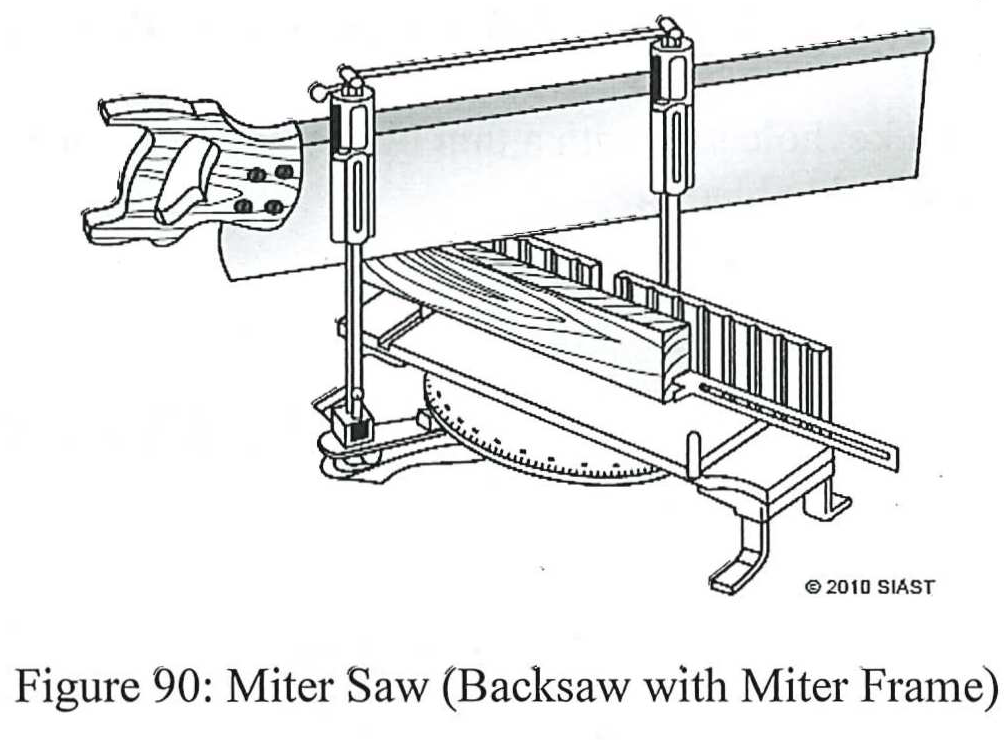

Backsaw

Backsaw

The backsaw contains a reinforced back which helps keep it straight during cuts. A larger variation, when used with a mitre box, is called a mitre saw which is used to produce accurate, precise angles.

Review Questions – 1.01.2

- How do the crosscut and rip saw differ?

- Which saw is best for cutting drywall?

- Why is the back of a backsaw reinforced?

- What is a saw kerf?

- What is the desirable angle for making the following cuts:

- Cross cut

- Rip cut

- Which side of the mark does the blade sit when making a cut?

- What can be done if the saw is binding during a rip cut?

- What is used when making duplicate cuts on a mitre saw?