Describe Types of Hammers and their Use

Topic 3 – Describe Types of Hammers and Their Use

Types of Hammers

There are many different hammers which are used to perform a variety of tasks. From carpentry, metal working, machining, to welding, roofing, and drywall, they vary in their design, specifically in their face and claw or “peen”. Some commonly used hammers and mallets used by carpenters is pictured below:

Safety and Usage

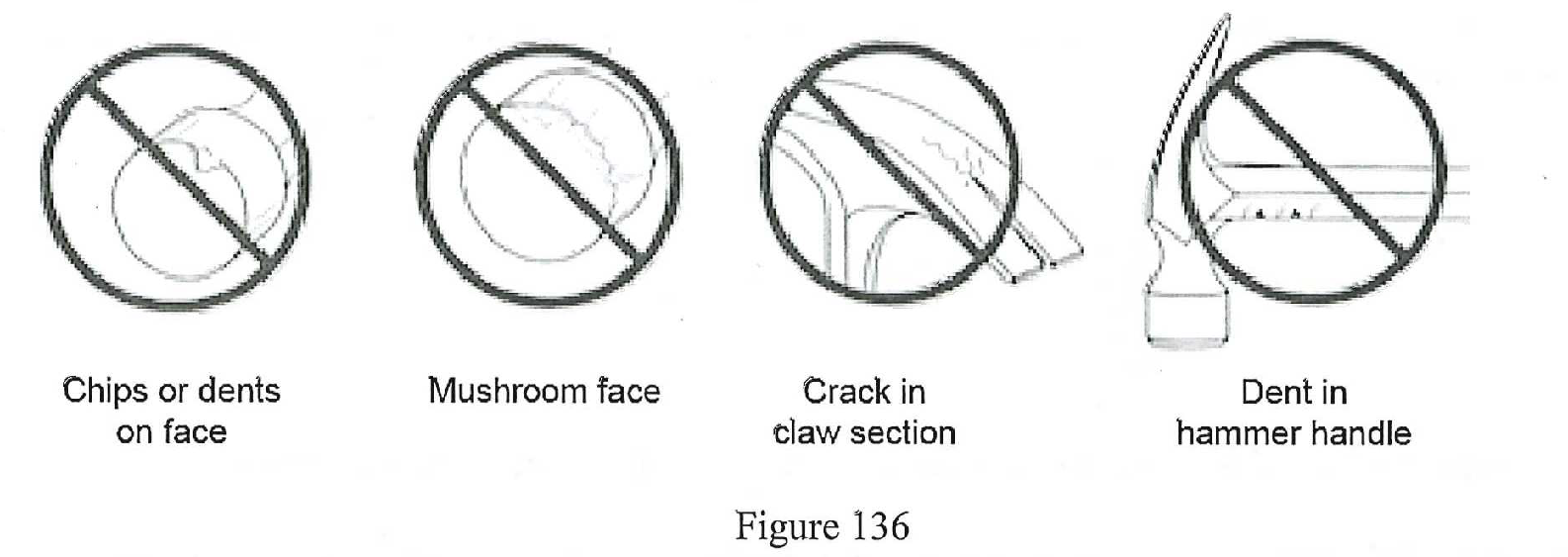

When using hammers, it is important to always wear eye protection. The hammer face may become damaged (mushroom) over time which can produce shards that may break off. Any mishits can also send a nail flying into the eyes of the user. Use the proper hammer for each task. Whether it’s striking a delicate surface or a cold chisel, the face of the hammer or material being struck can be unnecessarily damaged if the improper hammer is used. Any hammer that shows signs of the following should be discarded:

Claw Hammer

Claw Hammer

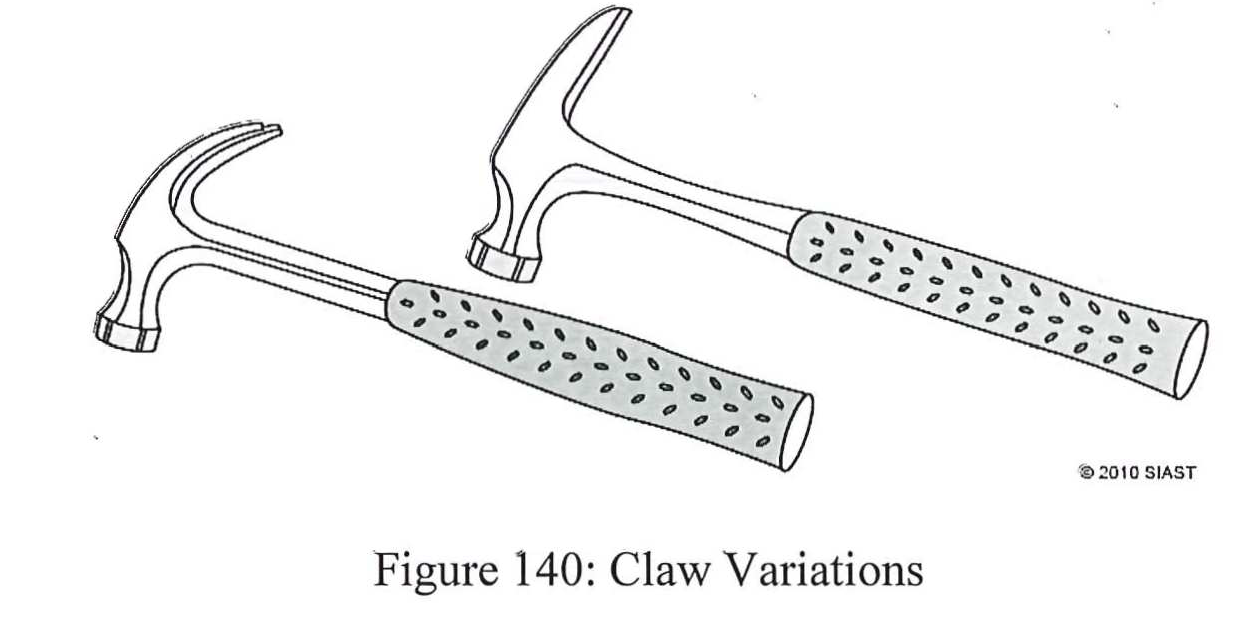

The most commonly used hammer by the carpenter is the claw hammer (pictured right). Faces can be either belled or flat with a smooth or hatched texture. The claw can be straight or curved. The hammer being chosen is dependent on the task and material being fastened into place.

Nailing

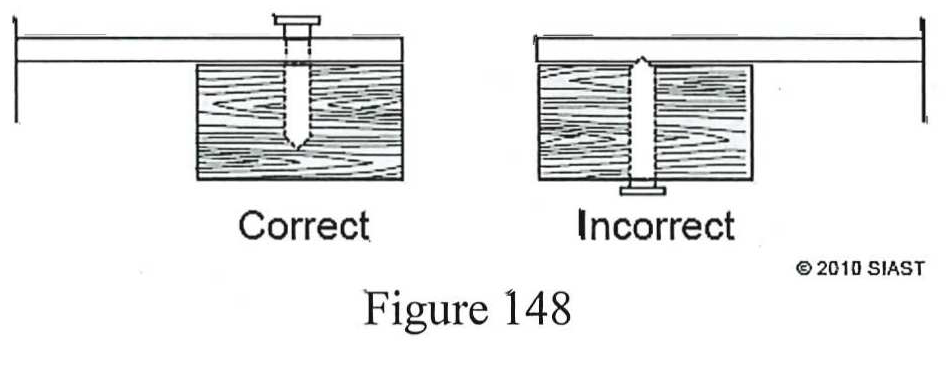

The most important consideration to make when nailing two pieces of stock together is their thickness. Always nail the thinner piece into the thicker piece to maximize the holding power of the nail (see figure 148 right).

The most important consideration to make when nailing two pieces of stock together is their thickness. Always nail the thinner piece into the thicker piece to maximize the holding power of the nail (see figure 148 right).

The most common nails have a diamond point which wedges itself between the grains. As a result, improper nailing tends to split wood along its grain. With some precaution, this can be avoided:

- Do not place nails too close together along the same grain, stagger nails along the same piece of wood

- Do not nail too close to the end of a board (or use a pilot hole)

- When nailing close to an edge or end, blunting the nail tip can prevent most splits

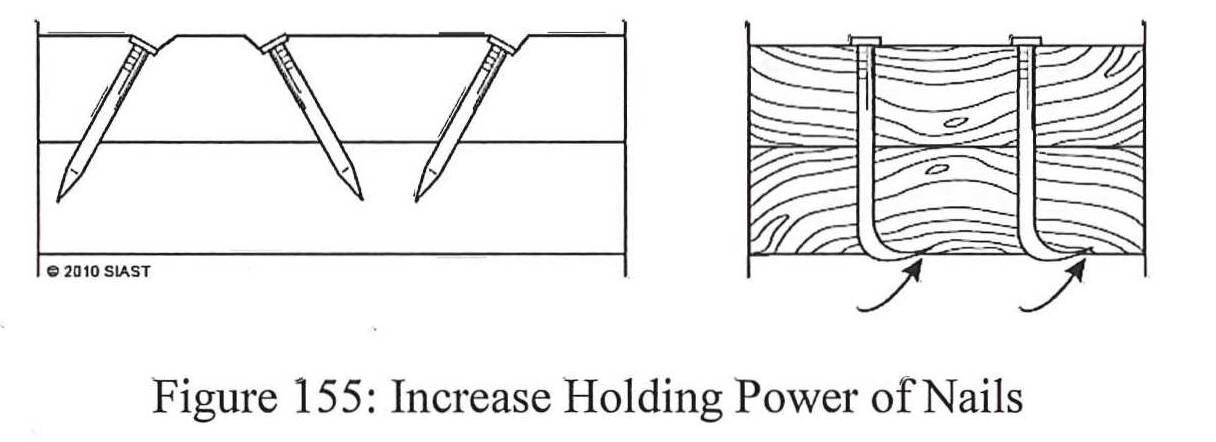

In order to increase its holding power nails can be toe-nailed (driven at an angle). This helps with preventing them from being pulled out. If a nail protrudes through the material, the tip can be bent over or “clinched” to further decrease it being pulled out.

When placing finish nails, it is important to not drive it home using the hammer face as this may damage the material. The nail is set almost flush and finished with a nail set which comes in a variety of sizes. The size chosen should be big enough to keep on the head of the nail but also not too big as to increase the hold made by the nail head.

Review Questions

- List the four types of hammer faces and give their specific use.

- What nailing pattern should be used when nailing two pieces together face to face?

- What is clinching a nail?

- What can be done to a nail to prevent splitting?

- How do you prevent splitting when nailing in hardwoods?

- True or false:

- Hammers are sized by the length of their handle

- The 4 common sizes of nail sets are 1/32”, 2/32”, 3/32”, 4/32”

- The “adze eye” is the hole in the head of a hammer to accommodate the handle.