Erects and Dismantles Scaffolding

Chapter A12 – Erects and Dismantles Scaffolding

Prerequisite Knowledge:

Topic 1 – Identify Requirements Common to All Scaffold Systems

Support Surfaces for Scaffolds

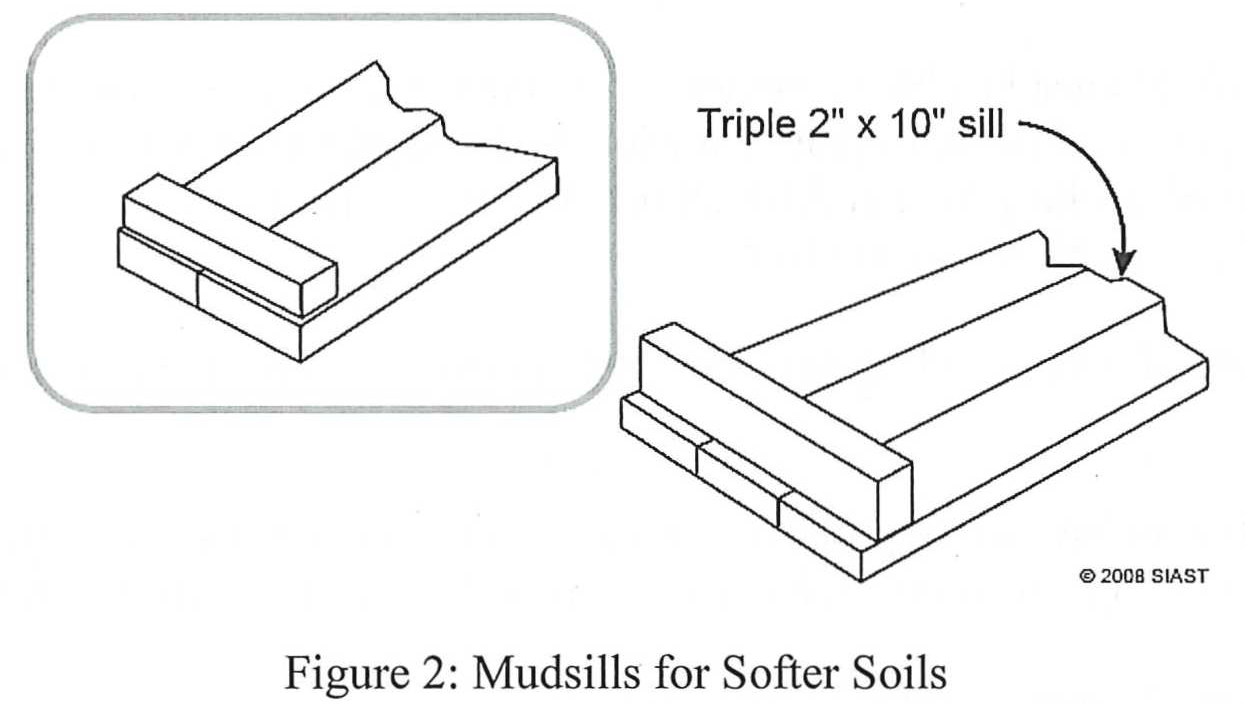

The first step in erecting a scaffold is providing a proper surface for it to be built on. Typically scaffolds required a mud sill which serves two purposes. It provides a level surface for which the scaffold will be built and spreads the load over a wider area. The OHS Regulations a mud sill should be at least 38 x 240 (2×10) and be continuous over at least two legs. It should also extend past the legs at least 150 mm at each end.

The soil conditions underneath a scaffold can have a great effect on its ability to hold up scaffolding. Soil should be compacted, and a wider mudsill bay be required for wet conditions. Wetter soil has a much lower bearing capacity as compared to dry soils.

The soil conditions underneath a scaffold can have a great effect on its ability to hold up scaffolding. Soil should be compacted, and a wider mudsill bay be required for wet conditions. Wetter soil has a much lower bearing capacity as compared to dry soils.

At the base of scaffolds, adjustable baseplate is recommended to provide the means to level the scaffolding. The use of blocks is not an acceptable means of leveling scaffolding.

Loading

The type of scaffold used is based on the height required and, most importantly, the load that it is required to support. When evaluating a load, everything must be considered including the workers, material, and tools. If a wood scaffold is used, a safety factor of 1:4 is required. For example, if it is required to support 1000 kg, it needs to be designed to support 4000 kg. For metal scaffolding, a safety factor of 2.2:1 is required.

In general, there are two types of scaffolding: light duty and heavy duty. They are designated by the weight they must be able to support. A light duty scaffold must be able to support 370 kg per lineal meter of platform width and, at the same time, 122.45 kg/m2. A heavy duty scaffold must be able to support 396 kg per lineal meter of work platform width and 367 kg/m2.

Tagging Systems (Industrial)

Any erection, dismantling, or alteration to scaffolding is required to be completed by a competent worker. To ensure the safe use of scaffolding, a tagging system is used to identify if a scaffold is safe for use, of limited use, and not safe for use. There are three tag colours used:

Inspection

When working on scaffolding, workers should maintain a constant lookout for defective or damaged parts. Any part that is damaged must be replaced and discarded or repaired. Look for broken welds, bent frames, or damaged connectors. For wooden scaffolding, check for cracks, splits, or knots.

Planks

Planks can be constructed of either wood or metal. Wooden planks can be made from sawn lumber, LVL, or LEG (Laminated Edge-Glued Lumber). Lumber is the most common and must be at least 38×240, No. 1 spruce or equivalent. LEG is simply 38×38 material glued together on edge to form a plank.

Metal scaffold planks are available in many sizes and ratings. Widths range from 10-20 inches, and lengths from 6-24 feet. The two most common ratings are for 250 and 500 lbs, with 750 lbs also being available. There are also length-adjustable aluminum planks available which should be used by only one person.

Decks and Platforms

Decking, or platforms, are also available and are wider than planks. Available in width of 24-36”, they are made of wood or metal. A platform must be at least 500 mm wide for light duty scaffolds and 1000 mm wide for heavy duty scaffolds. They may be used as ramps with slopes no steeper than a 1 in 5 slope.

Tie-Ins

When erecting freestanding scaffolding, the height must not exceed three times the smallest base dimension (usually the scaffold width). When this is limit is reached, OHS requires tie-ins be used to prevent the scaffold from tipping. They need to be able to resist both compression and tensile forces (see figure 5 below) and must be placed at the location of either a horizontal ledger or bearer. Guy wires may also be used if tying into the building is not an option. The angle should be between 30° and 60°, with 45° the most optimal.

Special consideration needs to be taken if tarps are placed on the scaffolding for hoarding. Extra ties must be used as the tarps act as a sail in the wind and put extra forces on the scaffolding.

Guardrails and Toe Boards

If a scaffold is more than 3000 mm above the ground, toe boards and guard rails are required. Guards should be 920-1070 mm high, with an intermediate rail and the toe board is required to be at least 140 mm high, tight to the platform.

Review Questions

Use the OHS Regulations to answer the following:

- Describe how to provide proper support so a scaffold does not settle over ground.

- How far must scaffold planks extend beyond their support?

- What is the maximum height of a rolling scaffold?

- What is the spacing of tie-ins for scaffolding?

- When is a guard rail required for scaffolding?

- What are the load requirements for light and heavy duty scaffolds?