Identify, Use, and Maintain Planes

Topic 4 – Identify, Use, and Maintain Planes

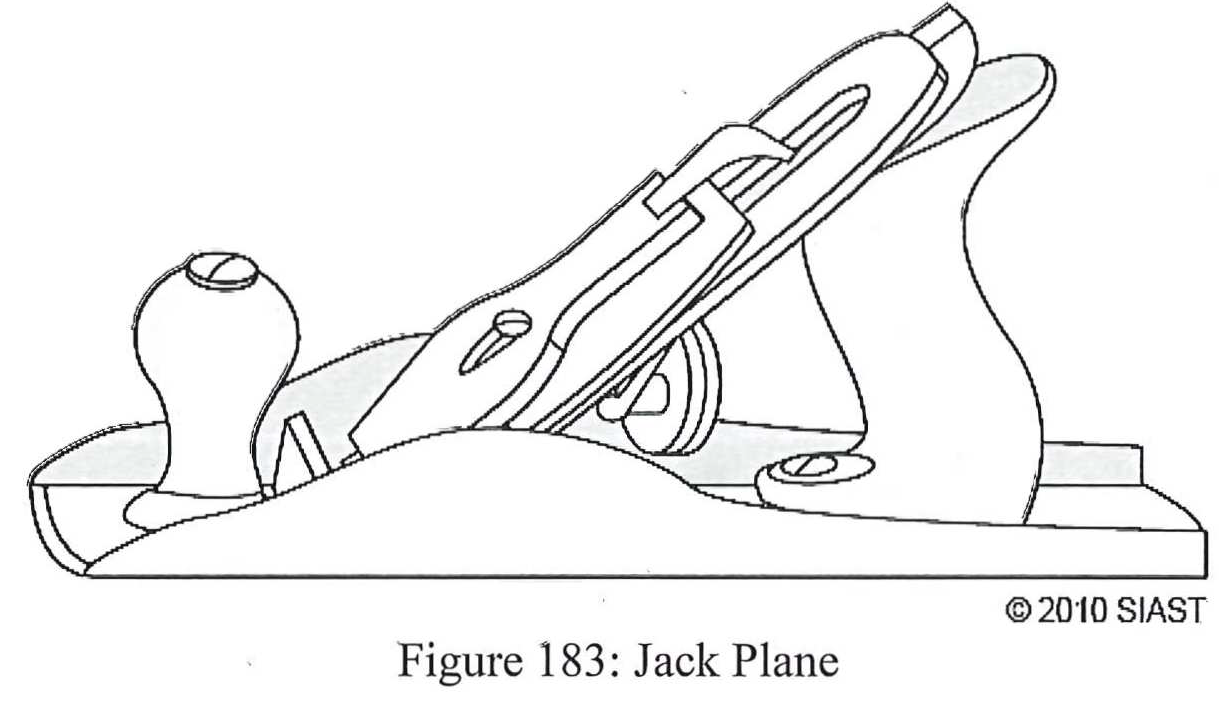

Bench Planes

The most common type of bench plane, which can be considered “general purpose” is the jack plane (pictured right). It is available in lengths from 355 mm to 380 mm and is capable of both planning and jointing stock. Another type of bench plane is the jointer, which is used to straighten and “true” an edge of a board. They are available in length of 500 mm to 600 mm. The longer sole helps it to achieve a straight, true surface on the stock edge.

The most common type of bench plane, which can be considered “general purpose” is the jack plane (pictured right). It is available in lengths from 355 mm to 380 mm and is capable of both planning and jointing stock. Another type of bench plane is the jointer, which is used to straighten and “true” an edge of a board. They are available in length of 500 mm to 600 mm. The longer sole helps it to achieve a straight, true surface on the stock edge.

Using Bench Planes

In order to effectively use a bench plane, the following should be observed:

- The blade must be sharp and set properly. The blade should project only slightly from the throat.

- The material should be secured in place before attempting to plane it.

- Plane with the grain.

- Push down on the knob when starting a cut. In mid-cut, apply even pressure on both the handle and knob. Apply pressure on the handle only when completing a cut.

- Periodically use testing tools at intervals to check for straightness using a straight edge such as a steel rule or square. Use as long a tool as possible and check for gaps between the stock and straight edge.

- If it becomes necessary to plane against the grain, use a very sharp cutting edge. The is common in highly figured grain such as curly maple.

Beyond surfacing stock, a plane can also be used to chamfer or bevel the edge of a board. If bevelling both ends and edges, it is advised to cut the edges before the ends to prevent splintering.

Storing and Maintaining Planes

It is important that planes are not stored resting on their blade. Lay the plane on its side or store it on a special block. Planes should also be lightly coated with oil from time to time to prevent rusting of the components.

Sharpening the blades of planes is a three stop method: grinding, honing, and stropping.

While grinding is not always necessary, it may be done if the blade is severely chipped or worn. Honing is done on a sharpening stone, starting with a coarse grit (800X or 1000X). After a fine feathered edge is achieved, move up to a finer grit (4000X or 8000X) until a keen edge is produced. While stropping is optional, it produces the ultimate cutting edge. The blade is run backwards over a piece of leather.

Specialty Planes

While bench planes are designed to cut along the face or edge grain, block planes are used to plane the end grain or very small pieces of wood. They are smaller than bench planes and have two distinct features that set them apart:

Review Questions

- What is the name of a general purpose plane?

- What plane has its bevel facing upwards?

- Planing should be done _________ the grain of the wood.

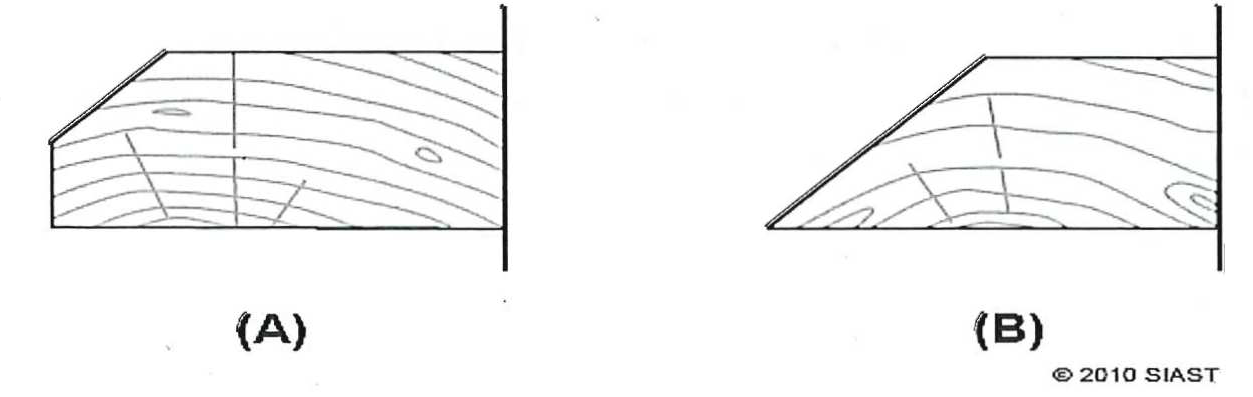

- Identify the types of edges in the following diagram:

- The bevel is __________ (up/down) on the iron of a jack plane.

- The larger the number designation on a sharpening stone means _________ cutting particles are within it.

Topic 5 – Identify and Use Abrading Tools, Abrasives, and Metal Cutting Tools

Files, Rasps, and Surforms

Files come in varying shapes, sizes, and cutting surfaces. They can be made to cut wood, metal, or other materials that need shaping. The “cut” of the file refers to the spacing and orientation of the teeth. The closer the teeth are together the smoother the cut.

Using, Maintaining, and Storing Files

When using a file, it is important that both ends of the file are held. The entire length should be used in the cutting action, which occurs on the forward stroke.

When files are stored, they should be kept separate from other tools to prevent damage to the teeth. Unlike many other tools, they should not be oiled as this will cause the teeth to be clogged. Therefore, they should be kept in a dry place. When dirty, they should be cleaned with a file card or file cleaner.

Other Types of Files

Other Types of Files

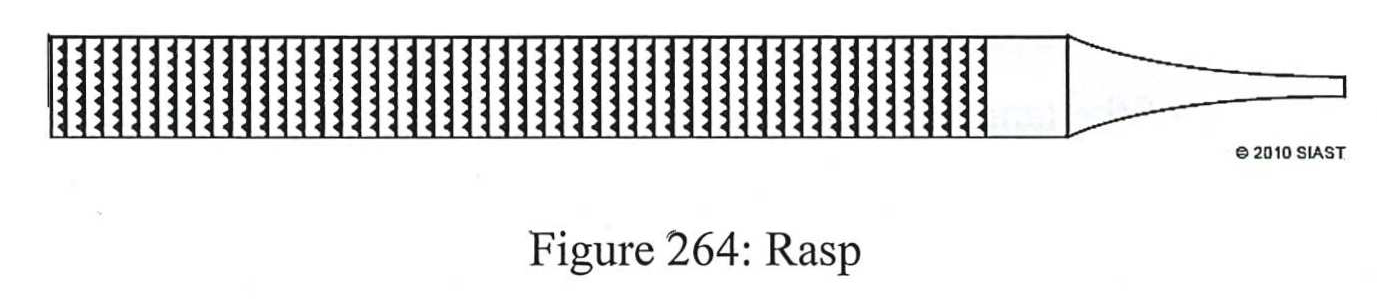

Rasps: Essentially very coarse files, they come in three basic shapes: round, half-round, and flat. Used for aggressive shaping.

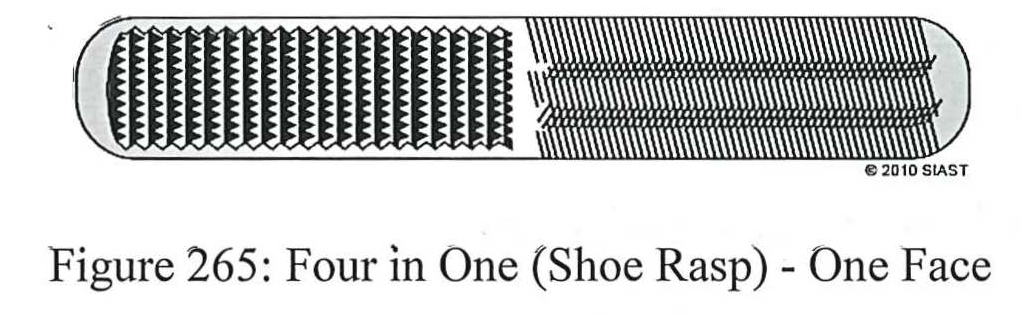

Shoe Rasp: this is a 4-in-1 tool that contains two rasp and file cuts in flat and half-round shapes. It is a convenient tool to have as it serves many filing needs in one tool.

Shoe Rasp: this is a 4-in-1 tool that contains two rasp and file cuts in flat and half-round shapes. It is a convenient tool to have as it serves many filing needs in one tool.

Surform: comes in a variety if configurations, they can be used to form and smooth both flat and irregular shapes. They have the added advantage of not plugging and therefore do not require the frequent cleaning as files do.

Surform: comes in a variety if configurations, they can be used to form and smooth both flat and irregular shapes. They have the added advantage of not plugging and therefore do not require the frequent cleaning as files do.

Sandpaper

Sandpaper consists of two parts: abrasives (grit or grain) and backing. The materials for each varies dependent on application and economy.

There are two classes of abrasives: Natural and Artificial. Examples of natural abrasives are garnet, flint, or emery. Artificial abrasives include silicon carbide and aluminum oxide (most common). Abrasives are graded according to size, also called “grit”. They can range from 40 all the way to 600 grit. As the number increases, the size of the particles decreases (smaller number = coarser cut).

Did you know? The term “Grit” refers to how manufacturers sift and filter the various abrasives they use. If you have a mesh screen that contains 40 slots over 1 square inch, it will let through much larger particles than one that has 220 slots over 1 square inch. This concept of how many slots there are over an area of 1 square inch in the sifting mesh is where the grit value comes from.

Four materials are used for sandpaper backing (from weakest to strongest): paper, cloth, combination, and fibre combinations. The choice of backing is highly dependent on application, with paper being used for largely hand sanding, and cloth or fibre backing for power tools.

There are two ways that the abrasive grains are fixed into the bonding agent: open coat and closed coat. With open coat, each grain is spaced at a pre-determined distance. The grains cover approximately 50-70% of the backing material. These coats are more resistant to clogging. Closed coat completely covers the surface of the backing material. This coating is used for heavy work such as aggressive sanding and hardwoods. This coating, while more durable, is prone to clogging.

Hacksaws

An extremely useful tool, the hacksaw is primarily used to cut metals. The blade is usually 150 – 300 (6-12”) mm long and 12 mm (1/2”) wide. While it is primarily used to cut material to length, it can also cut sheet metal (its bulky frame provides some limitations).

Hacksaw blades come with different “pitches” which is the space between each adjacent tooth. It is important to choose the correct blade depending on the job.

When replacing the blade, the teeth should be pointing toward the front so that the cutting action is done on the forward stroke. The blade should be tight enough to resist being bent, but not too much to put stress on the frame. Over time, the blade will wear and stretch (periodic tightening of the blade may be necessary). If the blade breaks in the middle of a cut, it is important to start a new cut as the old blade will have worn down; the new blade will have a wider “kerf” and will bind in the old cut.

Review Questions

- How do the cutting teeth on rasps differ from those on files?

- Files and rasps cut on the _______ stroke.

- Why should files be stored separately? How do prevent rusting when being stored?

- List four types of abrasives

- Which artificial abrasive is most suitable for sanding woodwork?

- Which has a coarser cut, 120 grit or 220 grit?

- When sanding a softwood such as pine, which coating would be preferred, open or closed coat? Why?

- Always sand ______ the grain.

- Name two factors that effect the selection of a hacksaw blade.

- What may happen if you cut too fast or hard with a hack saw?

- What should you do (if possible) if a hack saw blade breaks mid-cut? Why?