71 Hand Power Tools, Saws, and Knives

Learning Objectives

Name hand power tools, saws, and knives and list their purpose.

Hand Tools

Knives and saws are everyday tools in the meat processing industry.

Knives

Knife Anatomy

The following are parts of the anatomy of a knife. Each part serves a purpose.

Point: The very end of the blade. This is usually sharpened to a fine point, and can be used to pierce or score the surface of food.

Blade: The blade is the name given to the part of the knife which is used for cutting. It’s usually crafted from steel, although it may also be ceramic, titanium or even plastic.

Edge: This refers to the sharpened part of the blade, which is used for the majority of cutting work. The sharpness of the knife is dictated by how finely the edge is ground, and this will depend on both the quality of the knife and how often you sharpen it. It may be serrated (as with bread knives) or it may be straight.

Tip: The front part of the knife’s edge, just beneath the point, is called the tip. It’s the part of the blade which is normally used for delicate chopping and cutting work.

Spine: The spine is the blunt upper side of the blade, opposite to the cutting edge. The thickness of the spine gives strength to blade: as a rule, the thicker the spine, the stronger the blade. It’s also important for providing balance to the overall knife.

Heel: The heel is the lower edge of the blade, furthest from the tip, next to the bolster. It’s often the widest part of the blade. This part of the edge is most commonly used when the chef needs more strength or pressure to cut through thicker or tougher foods.

Tang: The tang is the unsharpened part of the blade which connects the blade edge to the handle. The tang is vital to the overall balance, weight, stability, and strength of the knife. The best knives are often considered to be those with a ‘full-tang’: one which runs from the end of the blade all the way to the butt. In some designs, the tang also functions as a handle.

Handle or scales: Sometimes called ‘scales’, the handle is the part of the knife grasped by the chef during use. It can be made from a number of materials, and may be straight or designed with finger grooves and other ergonomic features that make it easier to hold. Some knife manufacturers will dispense of the handle altogether, instead creating a knife using a single piece of steel, so that the tang also functions as a handle.

Bolster: The bolster is the raised area between the blade and the handle. It puts a small space between the chef’s hand and the blade, to stop the fingers from slipping down onto the blade during cutting work. It also provides additional weight to help balance the knife.

Handle fasteners, or rivets: These are the rivets or screws which fix the handle parts to the tang. Less expensive designs may forego the rivets and attach the handle to the tang using resin or epoxy instead.

Butt: The name was given to the end of the handle, at the very bottom of the knife.

Basic Knife Types

Chef Knife

A chef knife — sometimes called a chef’s or cook’s knife — has a long, broad blade with a straight edge. It is widest across the heel, tapering up to a finely pointed tip.

The curved blade of a chef’s knife allows it to rock back and forwards on a chopping board, which makes it the perfect tool for chopping and dicing lots of vegetables at once. The broad heel area means it can stand up to more pressure during heavy-duty chopping work, which is useful for cutting thicker or harder foods, like potatoes, onions, or parsnips.

A great all-rounder, a chef knife is one of the most versatile knives in the kitchen, perfect for everyday dicing and mincing tasks.

Utility Knife

A utility knife is a similar shape to a chef knife, but smaller and slimmer. Some utility knives also have a sharp tip that tapers up towards the spine, to allow for more intricate work.

A utility knife is good for chopping smaller foods and vegetables, like shallots. It shares many of the qualities of a chef knife, but it can be a useful tool when working with smaller food items, as the utility knife allows for more precise cutting work. So, when your cook’s knife is a little too big for the job, you’ll want to reach for a utility knife instead.

Paring Knife

A paring knife has a short, slim, evenly-sized blade with a pointed tip. It tends to be light, to allow for easy handling during delicate work.

The small but mighty paring knife is used to cut, chop and slice fruits and vegetables, but it can also be used for a multitude of other kitchen tasks. Despite their small size, paring knives will make light work of harder foods, like potatoes, while still being maneuverable enough to carry out delicate tasks like peeling, trimming, and removing seeds from fruit and veg.

Carving Knife

A carving knife is a long, slim knife, tapering to a sharp point. Sometimes called a slicing knife, a carving knife is one of the longest kitchen knives in the kitchen. Its narrow width means that it produces less drag as it cuts through food, allowing it to create cleaner, more uniform slices.

When it comes to serving meats like poultry, pork, lamb, or beef, a carving knife is the best tool for the job, as it will produce thin, neat, evenly-sized slices. It can also be used to tackle larger fruits and vegetables, such as melons or courgettes, which can be tough to slice through using smaller or broader knives.

The long, thin blades are also ideal for cutting cakes, as they’re long enough to cut perfect slices in one smooth cutting motion.

Cleaver or Butcher Knife

Cleavers — also called butcher knives — have a flat, rectangular-shaped blades. They come in a variety of sizes, depending on their intended use. They’re one of the broadest, heaviest knives, and sometimes feature a hole near the spine of the blade so they can be hung up when not in use.

A cleaver is used to chop up raw meat, either as part of the butchery process or to divide it into smaller portions before cooking. The large, heavy design means that it can even cut through bone, making it one of the best knives for raw meat prep.

Given its bulky size, this sort of knife is generally only used on raw meat, rather than cooked food. The broad, flat, heavy surface of cleavers can also come in handy for crushing garlic cloves or ginger against a chopping board.

Boning Knife

A boning knife is a slim blade with a very sharp edge, usually tapering upwards to a fine-pointed tip. It’s fairly short (usually only around six inches) and is usually rigidly constructed, although more flexible blades are available for delicate meat.

A boning knife is the best knife for cutting meat bones and trimming cartilage to create the perfect joint or cut before cooking. The pointed tip and slim blade make it a great choice for cutting around the bone without ruining the surrounding flesh.

The strong, rigid blade can also be used to cut through cartilage. When de-boning pork or beef, a slightly harder knife is best, while a more flexible blade will suit poultry. Boning knives are designed to be light and maneuverable, so you can count on them to be comfortable and easy to use.

Filleting Knife

A filleting knife is a long, slim knife with a flexible blade. It has a very sharp edge and a finely pointed tip for piercing through skin and allowing for intricate bone-removal work. It has a similar appearance to a boning knife, but the blade is thinner and more flexible.

The slim, flexible blade is perfect for removing bones without damaging the delicate flesh of the fish. They differ from other knives in that they’re often used to cut through food horizontally, rather than vertically — this allows chefs to cut around the backbone of whole fish to create perfect fillets. Filleting knives are great for all kinds of work involving fish, so they’re perfect if you like to try out lots of new recipes.

References

Mark. (n.d.). Types of knives: A guide to kitchen knives and their uses. UK Shop. Retrieved October 3, 2022, from https://www.allianceonline.co.uk/blog/2018/04/types-of-knives-a-guide-to-kitchen-knives-and-their-uses/#:~:text=Essential%20kitchen%20knives%2C%20including%20paring,tomato%2C%20peeling%20and%20nakiri%20knives

Saws

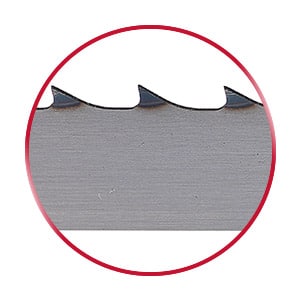

Saws have specialized teeth (cutting surfaces) that are specific to different purposes.

Butcher Blades

Unlike the other blades listed here, Butcher blades fall into the category of sawing blades, not slicing blades. This is because, when in use, Butcher blades typically end up removing some material as they cut or saw through. Butcher blades are considered the most aggressive type of food processing blades, and they are frequently used for carcass splitting and bone-in meat-cutting operations.

Scallop Blades

Originally sold as bread-slicing cutlery, today, scallop blades are one of the most versatile edge types on the market. They still have their place in bread-slicing applications, but nowadays they see more frequent use in the meat industry as they’ve proven incredibly effective at slicing boneless meat like chicken, beef, filets, or deli meats (ex: salami, pepperoni, etc.) and cheese.

Simmons, S. (2022, June 15). Food processing blades: An overview. Simmons Knife & Saw. Retrieved October 3, 2022, from https://simcut.com/2021/09/simmons-food-processing-blades/

[h5p id=”41″]

Power Tools

In the meat processing industry, power tools can assist in the accuracy of repetitive tasks such as boning. This can improve product yield (less waste) as well as repetitive strain injury for the worker. While there are many types of hand power tools, two in the pork processing industry are the blade bone puller and rib loosener.

Blade Bone Puller

When processing pork shoulders, it is necessary to remove the blade bone. This can be done by hand with a boning knife, however, it causes a lot of strain on the worker’s shoulders, elbows, and fingers. A blade bone puller reduces strain, can be operated with one hand, is fast, and reduces waste. The following video shows the operation of a blade bone puller.

Rib Loosener

Another example of a power hand tool in the pork processing industry is the rib loosener. Ribs need to be removed from pork middles and bellies. This is a manual repetitive process that requires a fair degree of strain and skill. The rib loosener is able to quickly and neatly remove ribs.