31 Steam

Learning Objectives

Explain the production of steam in the plant

Explain the transportation of steam in a plant

Explain the use of steam in a plant

Introduction

There are three states or phases of water: ice, water, and steam. When water is heated past the boiling point, it forms steam. When water boils on the stove what we see is a mixture of steam and tiny water droplets that have condensed. Pure steam is invisible.

Steam is particularly useful because water can store much more heat energy than most other substances. A large amount of heat is required to boil water and make steam (think of how long it takes for a kettle to boil water.) This energy is stored in the steam and can be used to heat something up or do work. Water and steam are also relatively safe and can be transported easily through pipes.

There are 2 types of steam:

- Culinary steam is used to heat food product because it is sanitary, has no chemical contaminants, and can come in contact with food, or a surface that touches food.

- Plant steam may have chemical additives and must not come in contact with food or food surfaces. Plant steam is used for heating the plant and doing mechanical work.

Definitions

- Condensation – conversion of water from vapour to a liquid. Water vapour from the air condenses on your cold glass on a hot summer’s day forming liquid water droplets.

- Culinary steam – steam that is suitable for direct contact with food or surfaces that contact food.

- Heat transfer – heat energy moving from one object to another as the result of a temperature difference.

- Indirect heating – heat moving through an object into another. Heat can be easily transferred from a flame or steam, through a steel pot, into food.

- Plant steam – steam that is used for plant heating or other mechanical work. Plant steam can not come in contact with food.

Generation

Chemical energy contained in coal, gas, oil, or other boiler fuel is converted into heat energy when burned. This heat energy is transmitted through the wall of the boiler furnace to the water. The temperature of the water increases due to this added energy until it boils. The steam produced is contained in the closed boiler system- it has no place to escape so it produces pressure. Steam pressure can be very dangerous but is also useful in operating steam powered equipment.

Effective Heat Transfer

Steam is used to heat food products. The most efficient transfer of heat occurs when there is a large temperature difference between the steam, and the food product. However, certain things can get in the way and reduce the efficiency of the heat transfer.

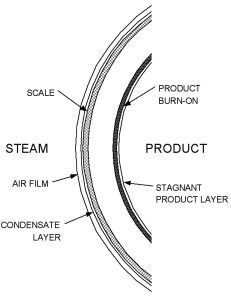

Figure 1 shows examples of layers of films that can build up on the product and steam side of a heat transfer surface. Some of the most common examples of these films in food processing operations are: stagnant layers of product, burned-on product, rust, scale, water (condensate), layers of single-celled organisms, and air. These films must be eliminated or reduced to optimize heat transfer.

Stagnant layers of product can be removed (or reduced) by agitation, especially surface-scraping agitation. Product burn-on can be minimized by surface-scraping agitation and regulation of the heat-transfer surface temperature. Rust, scale and organic films may be controlled by methods such as frequent cleaning of heat-transfer surfaces, using corrosion-resistant materials, and boiler-water additives (in the case where steam does not contact food or food surfaces.)

Examples of Food Processing Equipment that use Steam

Examples of typical steam-using equipment in food processing plants are given in this section.

Shell and Tube Heater

Shell and tube heaters are commonly used to heat a flowing liquid by condensing plant steam or a pumped heat transfer media. A thin-tube wall separates the heating media from the product being heated. In the case of a pumped heat-transfer media (such as hot water), steam is often used to heat the media in a separate heat exchanger. Figure 2 shows a typical shell and tube heater.

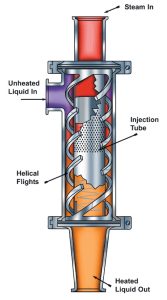

Steam Injection Heater

Steam injection heating for food products is a direct-contact process in which culinary steam is mixed with a pumpable food (or ingredient). Heating occurs when the steam transfers some of its internal energy to the food product. Since the steam directly contacts the food product and the condensate becomes incorporated into it, the steam source must be culinary. Typical steam injection units are compact, inexpensive and simple to control. An example is provided in figure 3.

Steam Infusion

Steam infusion is another method of steam heating where the food product is heated by relatively low-pressure, culinary steam. A steam infusion device usually incorporates a chamber where the product is cascaded through a steam environment.

Steam Sparger

Steam sparging is common in open tanks or kettles containing liquid products or water. Culinary steam is bubbled into the liquid from nozzles located near the bottom of the tank.

Steam Jacketed Kettle

A jacket, used to distribute steam over a wide surface area, consists of a thin space formed between two, parallel, metallic surfaces. Steam jackets are typically used to heat bulk products held in tanks and kettles. An example of a steam-jacketed kettle is shown in figure 4. Condensing steam, held captive within the jacket, transfers heat to the product in the kettle. A layer of insulation over the jacket protects operators and conserves heat.

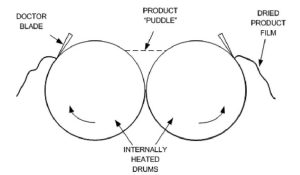

Drum Dryer

Drum dryers consist of one or more internally heated, metallic drums on which a thin, uniform layer of wet material is applied. In food processes, plant steam is often selected as the heat transfer media because it does not come in contact with the food product. An example of a drum dryer is shown in figure 5.

Humidifier

Certain drying and curing processes require humidification of the air surrounding the product to control the drying rate. Culinary steam can be injected directly into a drying chamber or into a ventilation air duct.

Space or Air Heater

Plant steam is contained in various enclosures (such as tube coils or radiators) and used to heat air.

Steam-In-Place (SIP)

Culinary steam is used to achieve high temperatures and moisture levels required to sterilize enclosed surfaces (such as closed tanks, pipes and valves) in food processing equipment.

Mixing Tee

Mixing Tees are typically found in a wash-down hose station. Culinary steam is mixed with potable water to produce hot water used in washing operations (see figure 6).

Conclusion

Steam provides a convenient means for transferring energy throughout a food processing plant. When properly engineered and installed, a steam system is reliable, safe and economical. A wide choice of fuel sources can be used to generate steam contributing to its flexibility as a heat transfer vehicle. Steam may be used for indirect heating of food products or may be directly incorporated in foods for heating using a wide array of commercially available equipment. In addition, steam can be used for non-food processing activities (e.g. space and surface heating) throughout the facility. Finally, steam can be precisely controlled, helping to make processes consistent and repeatable.

References

Bowser, T. J. (2017, July 1). Steam basics for food processors – Oklahoma State University. Steam Basics for Food Processors | Oklahoma State University. Retrieved September 18, 2022, from https://extension.okstate.edu/fact-sheets/steam-basics-for-food-processors.html