54 Packaging Material, Method, and Storage

Learning Objectives

Explain the purpose and method of packaging, material selection, and storage

Packaging Systems Used in the Food Industry

- The main goal of food processing is to increase the shelf life and palatability of foods, make them safe and enjoyable to consume.

- This is accomplished using physical, chemical and microbiological transformation of raw materials into finished goods.

- One of the most important steps in food processing is packaging. Food packaging will protect food products from outside influences and damage. Food packaging can be grouped into chemical, physical, and microbiological protection.

Chemical Protection

- Minimizes compositional changes triggered by environmental influences such as exposure to gases (typically oxygen), moisture (gain or loss), or light (visible, infrared, or ultraviolet).

- Many different packaging materials can provide a chemical barrier.

-

Glass and metals provide a nearly absolute barrier to chemical and other environmental agents, but few packages are purely glass or metal since closure devices are added to facilitate both filling and emptying.

- Closure devices may contain materials that allow minimal levels of permeability.

- Plastic packaging offers a large range of barrier properties; however, it is generally more permeable than glass or metal.

Biological Protection

- Provides a barrier to microorganisms (pathogens and spoiling agents), insects, rodents, and other animals, thereby preventing disease and spoilage.

- In addition, biological barriers maintain conditions to control senescence (ripening and aging).

- Such barriers function by preventing access to the product, preventing odor transmission, and maintaining the internal environment of the package.

Physical Protection

- Shields food from mechanical damage and includes cushioning against the shock and vibration encountered during distribution.

- Typically developed from paperboard and corrugated materials, physical barriers resist impacts, abrasions, and crushing damage, so they are widely used as shipping containers and as packaging for delicate foods such as eggs and fresh fruits.

- Appropriate physical packaging also protects consumers from hazards. For example, child-resistant closures hinder access to potentially dangerous products.

- In addition, the substitution of plastic packaging from products ranging from shampoo to soda bottles has reduced the danger from broken glass containers.

- Slow Deterioration: Food packaging can slow product deterioration, retain the beneficial effects of processing, extend shelf-life, and maintain or increase the quality and safety of food.

- Contain the Food: The goal of food packaging is to contain food in a cost-effective way that satisfies industry requirements, consumer desires, maintains food safety, and minimizes environmental impact.

Packaging Categories

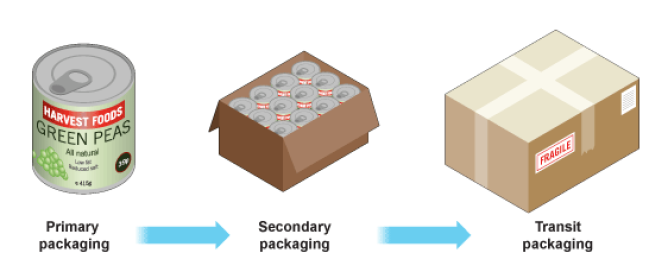

Each level of packaging applied is categorized based on contact with the product:

- Primary Packaging – Direct Contact with the Consumer Good (e.g. food)

- Secondary Packaging – Surrounds the Primary Packaging

- Tertiary (Transit) Packaging – Surrounds the Secondary Packaging

Materials and Design Used in Food Packaging

- Package design and construction play significant role in determining the shelf life of a food product.

- The right selection of packaging materials and technologies maintains product quality and freshness during distribution and storage.

- Materials that have traditionally been used in food packaging include glass, metals (aluminum, foils and laminates, tinplate, and tin-free steel), paper and paperboards, and plastics.

- A wider variety of plastics have been introduced in both rigid and flexible forms.

- Today’s food packages often combine several materials to exploit each material’s functional or aesthetic properties.

- As research to improve food continues, advances in the field may affect the environmental impact of packaging.

Glass

- Glass has an extremely long history in food packaging.

- Glass containers used in food packaging are often surface-coated to provide lubrication in the production line and eliminate scratching or surface abrasion and line jams.

- Because it is odorless and chemically inert with virtually all food products, glass has several advantages for food-packaging applications.

- It is impermeable to gases and vapors, so it maintains product freshness for a long period without impairing taste or flavor.

- The ability to withstand high processing temperatures makes glass useful for heat sterilization of both low-acid and high-acid foods.

- Glass is rigid, provides good insulation, and can be produced in numerous different shapes; it is also reusable and recyclable.

- Disadvantages:

- Despite efforts to use thinner glass, its heavy weight adds to transportation costs

- Another concern is brittleness and susceptibility to breakage from internal pressure, impact, or thermal shock

- Food safety hazard of broken glass

Metal

- Metal is the most versatile of all packaging forms.

- It offers a combination of excellent physical protection and barrier properties, formability and decorative potential, recyclability, and consumer acceptance.

- The two metals that are most predominately used in packaging are Aluminum and Steel.

Laminates and Metallized Films

- Lamination of packaging involves the binding of aluminum foil to paper or plastic film to improve barrier properties.

- Thin gauges facilitate application.

- Lamination to plastic enables heat sealing ability but the seal does not completely bar moisture and air.

- Laminated aluminum is relatively expensive and it is typically used to package high value foods such as dried soups, herbs, and spices.

- A less expensive alternative to laminated packaging is metallized film.

- Metallized films are plastics containing a thin layer of aluminum metal

- These films have improved barrier properties to moisture, oils, air, and odours, and the highly reflective surface of the aluminum is attractive to consumers.

- Metallized films are more flexible than laminated films and are mainly used to package snacks.

[h5p id=”25″]

Advantages to Using Plastics

- Because they are fluid and easy to form, plastics can be made into sheets, shapes, and structures, offering considerable design flexibility.

- Plastics can be chemically resistant, inexpensive and lightweight with a wide range of physical and optical properties.

- Many plastics are heat sealable, easy to print, and can be integrated into production processes where the package is formed, filled, and sealed in the same production line.

Types of Plastics

- Multiple types of plastics are being used as materials for packaging food.

- They include polyethylene (HDPE & LDPE), polyolefin, polyester, polyvinyl chloride, polyvinylidene chloride, polystyrene, polyamide, and ethylene vinyl alcohol.

- Of more than 30 types of plastics used as packaging materials; polyolefins and polyesters are most common.

Paper and Paperboard

- The use of paper and paperboards for food packaging dates back to the 17th century with accelerated usage in the later part of the 19th century.

- Paper and paperboard are sheet materials made from an interlaced network of cellulose fibers derived from wood by using sulfate and sulfite.

- The fibers are then pulped and/or bleached, treated with chemicals and strengthening agents to produce the paper product.

- The additives used in paper and paperboard food packaging are regulated in both the US and Canada.

- Paper and paperboards are commonly used in corrugated boxes, milk cartons, folding cartons, bags and sacks, and wrapping paper.

- Tissue paper, paper plates, and cups are other examples or paper and paperboard products.

Food / Package Interaction

- Plays an important role in the proper selection of packaging materials for various food applications.

- Each packaging material has different inherent properties.

- These properties affect the selection of which material is best for a particular food, given the characteristics of that food.

- Food/package interaction involves the transportation of low molecular weight compounds such as gases or vapours and water from:

- The food through the package

- The environment through the package

- The food into the package

- The package into the food

Modified Atmosphere Packaging (MAP)

- Modified atmosphere is the practice of modifying the composition of the internal atmosphere of a package in order to improve the shelf life of the product.

- The modification process most often used is to lower the amount of oxygen (O²), reducing it from 20.9% to 0%, in order to:

- Slow down the growth of aerobic microorganisms

- Slow the speed of oxidation reactions

- Types of MAP Packaging

- Gas Flushing

- Barrier Packaging Films

- Scavenger or Desiccant Packs

- On-Package Valves

Smart Packaging vs. Connected Packaging: What’s the Difference?

Gas Flushing

Gas flushing displaces the ambient oxygen with a harmless gas before the package is sealed. The removed oxygen can be replaced with:

- Nitrogen (N²), commonly known as an inert gas

- Carbon dioxide (CO²), which can lower the pH or inhibit the growth of bacteria

- Carbon monoxide (CO), used for keeping the red colour of meat

The injected gas can also act as a filler to maintain conformity.

Barrier Packaging Films

Barrier packaging films are an example of passive modified atmosphere packaging.

Select packaging films act as barrier packaging by providing decreased permeability to moisture and oxygen. Examples include:

- LDPE: low-density polyethylene

- PVC: polyvinylchloride

- PP: polypropylene

Scavenger or Desiccant Packs

Scavenger or desiccant packs are added inside of packaging with the consumer good to absorb ambient moisture and/or oxygen from the interior of the package.

These packs are often found in pharmaceutical containers (pill bottles) or within clothing and footwear items prone to the effects of moisture.

On-Package Valves

One-way valves are added to the exterior of packaging. The valves allow certain gases to escape without allowing any gases into the package.

Products that may release gases after packaging, such as coffee, can benefit from the addition of an on-package valve to release pressure. In addition, the valves can also be used to allow air to escape packages and help with packing and palletization.

Microwave Packaging

- Metallized films are used as a susceptor for cooking in microwave ovens. These increase the heating capacity and help make foods crisp and brown.

- Susceptors: Microwave susceptors are used to provide additional thermal heating on the outside of food articles that are heated in a Microwave Oven.

- Typically, aluminum metallized polyester (PET) sheets, whereas the aluminum is deposited with very low thickness