66 Batching Equipment

Learning Objectives

Demonstrate equipment set up and calibration

Batching equipment is useful in ensuring ingredients are encorporated into batches in precise amounts, and mixed thouroughly throughout the batch. The best batching equipment addresses accuracy of ingredient amounts, product traceability, and flexibility to configure for different recipes.

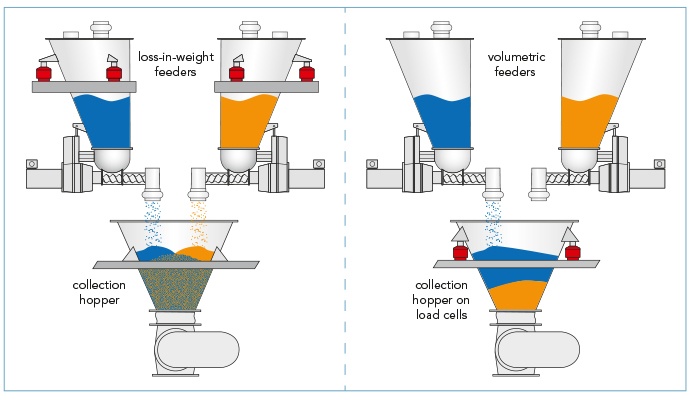

There are two types of batching techniques: Gain In Weight (GIW) and Loss In Weight (LIW).

Gain In Weight (GIW)

Gain in Weight (GIW) processing measures the weight gain in the collection hopper. The ingredient feeder hoppers are opened or closed depending upon the required weight as measured form the collection hopper. Ingredients are dispensed one after the other, so this process can take some time, especially if there are many ingredients.

Loss In Weight (LIW)

Loss In Weight (LIW) processing measures the weight comming out of the ingredient hoppers. All ingredients can be dispensed at the same time leading to a faster batching process. This method is also more precise, and so it is used for dispensing micro ingredients such as food additives.

Modern food batching equipment can keep track of product lots which is essential for traceability and food safety. Also, some machines offer automatic bin level checking so the producer can tell if there will be enough ingredient to complete the batch run.

[h5p id=”33″]

References

Nowak, S. (2021, March 1). Liw versus GIW dispensing defined. Coperion. Retrieved October 3, 2022, from https://www.coperion.com/en/news-media/newsletter/2021/pharma-in-focus-edition-012021/liw-versus-giw-dispensing-defined

Rowlands, R. (2021, September 9). Benefits of modern batching systems. Pet Food Processing RSS. Retrieved October 3, 2022, from https://www.petfoodprocessing.net/articles/15070-benefits-of-modern-batching-systems