37 Proper Use of Chemicals

Learning Objectives

- Describe first aid procedures if chemical contact is made considering data on MSDS

- Demonstrate proper use of chemical including calculation of strength, contact time, and correct chemical for the job considering information on MSDS

- Find potential hazards in chemical storage conditions referencing information on MSDS

Introduction

This information is intended as a quick reference and overview of first aid procedures. completing this section does not make you qualified to perform first aid. Refer to your official first aid training for more information.

Most of what needs to be done in case of accidental contact is dictated by the Material Data Safety Sheet (MSDS.) This chapter gives only a brief review of the MSDS.

[h5p id=”14″]

Material Safety Data Sheet

A Material Safety Data Sheet (MSDS) is a document that contains information on the potential hazards (health, fire, reactivity and environmental) and how to work safely with the chemical product. It is an essential starting point for the development of a complete health and safety program. It also contains information on the use, storage, handling and emergency procedures all related to the hazards of the material. The MSDS contains much more information about the material than the label. MSDSs are prepared by the supplier or manufacturer of the material. It is intended to tell what the hazards of the product are, how to use the product safely, what to expect if the recommendations are not followed, what to do if accidents occur, how to recognize symptoms of overexposure, and what to do if such incidents occur.

In Canada, every material that is controlled by WHMIS (Workplace Hazardous Materials Information System) must have an accompanying MSDS that is specific to each individual product or material (both the product name and supplier on the MSDS must match the material in use).

Always be familiar with the hazards of a product BEFORE you start using it. You should look at a MSDS, match the name of the chemical on your container to the one on the MSDS, know the hazards, understand safe handling and storage instructions, as well as understand what to do in an emergency.

https://www.ccohs.ca//oshanswers/legisl/msdss.html

There are nine sections of data required on a MSDS, however the most important one for this chapter is regarding first aid measures. (Some MSDS provided by companies are in a 16 heading format.) The following is a link to a MSDS for common household bleach.

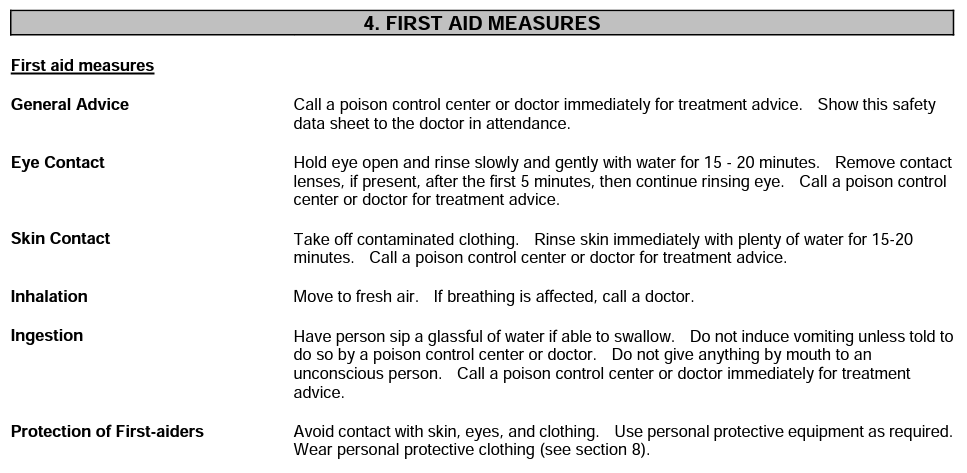

This is the section of the MSDS for bleach pertaining to first aid.

On first glance of this section, in general, you can determine that:

- Call a doctor, and have the MSDS on hand.

- If bleach is in contact with the eyes, rinse at an eyewash station for 15 – 20 minutes.

- If bleach is in contact with the skin, rinse for 15 – 20 minutes.

- If bleach is inhaled, move to fresh air.

- If bleach is ingested (swallowed) sip water.

First Aid for Chemical Contact

First aid for chemical contact will be studied in detail in your first aid course. This section will cover some general information regarding chemical contact.

In order to know what first aid procedures to follow, it is essential that you know what chemicals are present in your workplace. Consult your chemical inventory and the First-aid measures section on the Safety Data Sheets (SDSs) for those products. Create a list of chemicals, their properties and their corresponding first aid requirements. Be sure that the emergency first aid providers in your workplace have the appropriate training and authority (if necessary) to respond to the effects of chemicals used at your workplace.

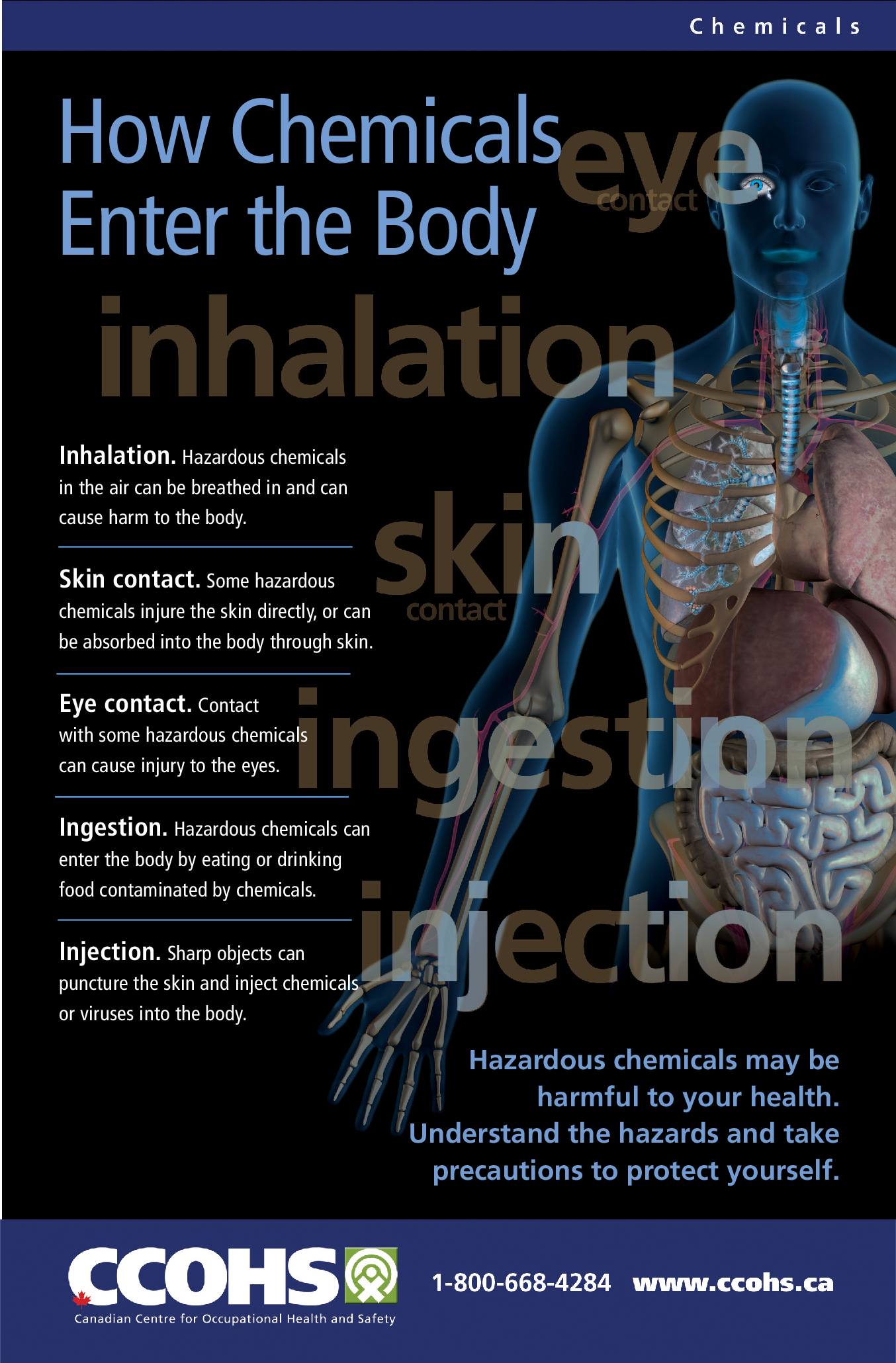

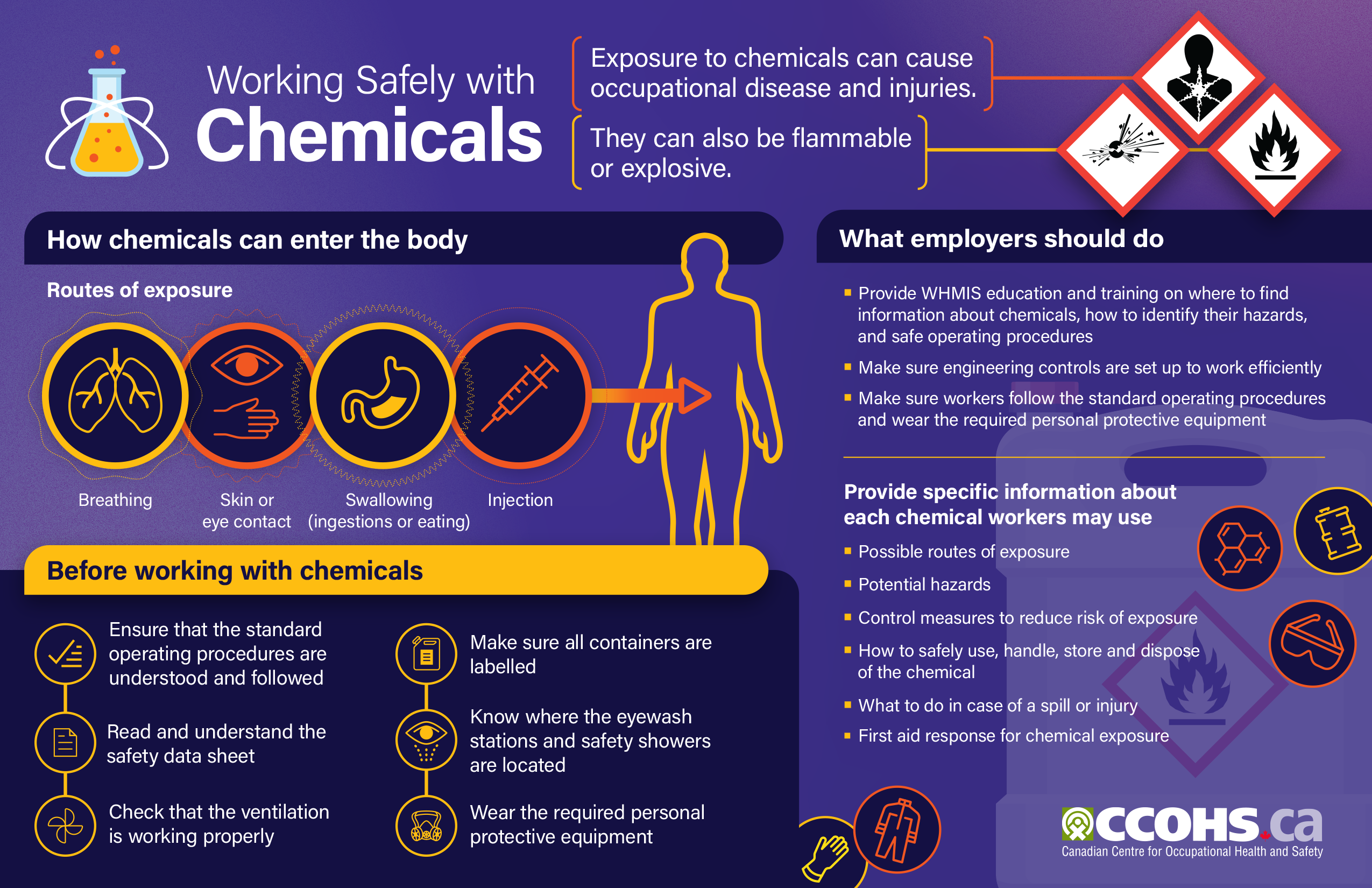

How Chemicals Enter the Body

Routes of exposure:

- Breathing

- Skin or eye contact

- Swallowing (ingestion or eating)

- Injection

How to Work Safely with Chemicals

Before working with chemicals

- Ensure that the standard operating procedures are understood and followed

- Read and understand the safety data sheet

- Check that the ventilation is working properly

- Make sure all containers are labelled

- Know where the eyewash stations and safety showers are located

- Wear the required personal protective equipment

What employers should do

- Provide WHMIS education and training on where to find information about chemicals, how to identify their hazards, and safe operating procedures.

- Make sure engineering controls are set up to work efficiently.

- Make sure workers follow the standard operating procedures and wear the required personal protective equipment.

Provide specific information about each chemical workers may use

- Possible routes of exposure

- Potential hazards

- Control measures to reduce risk of exposure

- How to safely use, handle, store and dispose of the chemical

- What to do in case of a spill or injury

- First aid response for chemical exposure

In general, here are some misconceptions that people may have about chemical contact:

How long should the skin or eyes be flushed with water in the event of a chemical exposure?

Most standard sources recommend that water rinsing/flushing following skin or eye contact with a chemical should continue for 15 or 20 minutes. However, all chemicals do not cause the same degree of effects (some are non-irritants while others can cause severe corrosive injury). At the present time, there is insufficient scientific evidence available to properly address the question of how long flushing should continue. However, it makes sense to tailor the duration of flushing to the known effects of the chemical or product, as follows:

- 5-minutes for non-irritants or mild irritants

- 15-20 minutes for moderate to severe irritants and chemicals that cause acute toxicity if absorbed through the skin

- 30 minutes for most corrosives

- 60 minutes for strong alkalis (e.g., sodium, potassium or calcium hydroxide)

It is very important that water flushing start immediately following skin or eye contact with a chemical. It is better if complete water flushing occurs on-site. However, moving the exposed person to an emergency care facility earlier may be necessary depending on their condition (e.g., compromised airways, breathing, or circulation) and/or the availability of a suitable water supply. If it is necessary to transport the person before completing flushing on-site, flushing should continue during emergency transport, taking proper precautions to protect emergency services personnel.

Note that the manufacturer/supplier may also specify a cleansing agent (e.g., non-abrasive soap) if appropriate, or may recommend an alternative agent in exceptional cases if water is clearly inappropriate.

When should vomiting be induced following ingestion of a chemical?

Vomiting should NOT be induced following ingestion of a chemical in an occupational setting unless advised by a Poison Centre or doctor. Some of the arguments against inducing vomiting are:

- The amount of chemical accidentally ingested by an adult is generally estimated to be very small (14-21 mL or about 0.5-0.75 oz).

- There is no conclusive evidence that people who swallow a chemical and who do have their stomachs emptied have more successful outcomes than people who do not.

- There can be significant risks associated with inducing vomiting especially in emergency situations.

- There does not seem to be a reliable and safe first aid procedure for inducing vomiting in adults.

- Medical attention is usually available quite quickly in most situations.

In the event of a chemical ingestion, the best course of action is to call your local Poison Control Centre or a doctor and follow their advice. They will ask you specific questions, such as the name of the product swallowed, the amount swallowed and the condition of the person who swallowed the chemical. This information will assist them in determining the best course of action.

Should water or milk be given to dilute a chemical that has been ingested?

Much of what we know about the benefits of diluting an ingested chemical with water or milk is based on in vitro (test tube) and ex vivo (using harvested rat esophagi) studies.

Based on their evaluation of the evidence for dilution with milk or water, the American Heart Association and American Red Cross recommend that people should not take anything by mouth for an ingested poison unless specifically told to do so by a doctor or the Poison Control Centre.

How do I know which antidote to have available for the chemicals in my workplace?

It is a common misperception that antidotes are available for most chemical poisonings. True antidotes are the exception rather than the rule.

Activated charcoal is sometimes considered to be an antidote. Activated charcoal works by binding the chemical in the stomach so it cannot be absorbed through the stomach. According to the American Academy of Clinical Toxicology and the European Association of Poisons Centres “the administration of activated charcoal may be considered if a patient has ingested a potentially toxic amount of a poison (which is known to be adsorbed to charcoal) up to 1 hour previously…”. In general, the administration of activated charcoal is NOT considered a first aid procedure. Activated charcoal may be administered in the emergency department or under medical supervision.

Some chemical classes do have true antidotes – cyanides and organophosphate pesticides are good examples. You can determine which chemicals used in your workplace have antidotes by consulting with a doctor with certification in medical toxicology or occupational medicine, or the manufacturer/supplier of your product. These specialists can advise you on situations where it may be appropriate to store an antidote onsite. Special training of first aid providers will be required. In some cases, it may be appropriate to request your local hospital to stock an antidote that must be administered by a medical professional.

https://www.ccohs.ca/oshanswers/chemicals/firstaid.html

Proper Use of Chemicals

When used according to specification, chemicals are a safe and essential means of sanitation.

Calculating Chemical Strength

The following pictures demonstrate common referants to the units of measure: millilitre, 12 Fl Oz, 32 Fl Oz, 500 ml, 4 L, 5 Gal.

Example

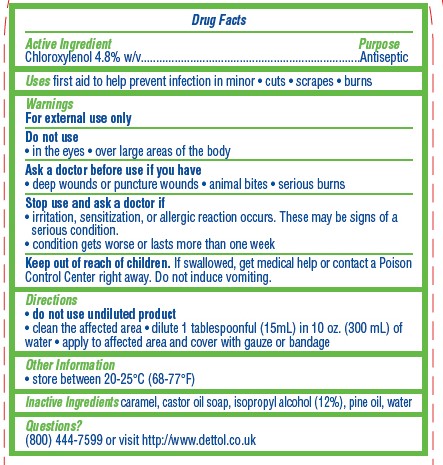

Using the information in the above lable, how much chemical would you need for a 32 oz spray bottle? a 500 ml bottle? In each case, what would referant (pictured above) would you use to roughly describe how much chemical to use?

Example

Using the information in the above lable, how much chemical would you need to fill a 5 gallon pail? What would referant (pictured above) would you use to roughly describe how much chemical to use?

References

https://xo2.com.au/blog/articles-2/post/how-to-quickly-calculate-cleaning-chemical-dilution-rates-and-ratios-219, accessed August 28, 2022.

Resources

Information from this section is gathered from the Canadian Centre for Occupational Health and Safety (CCOHS) and can be accessed for free at: https://www.ccohs.ca/oshanswers/chemicals/firstaid.html

For additional detailed information and references to scientific studies refer to: https://www.ccohs.ca/products/publications/firstaid/