69 Recording Equipment Failures

Learning Objectives

Summarize details to record equipment failures and corrective actions.

Records are at the core of a successful maintenance program. Records document maintenance and calibration activities to plan future activities and equipment replacement.

Preventative Maintenance and Callibration Program (PMC)

A written PMC Program includes:

- The person responsible for each task

- Layout, blueprint or floor plan of plant showing locations of equipment and infrastructure (e.g. boiler rooms and compressors)

- Manufacturer’s documentation such as manuals, drawings and parts lists

- Description of maintenance activities such as lubrication, cleaning, or changing filters

- Description of calibration activities such as calibrating scales, and sensors

- SOPs to be followed for each activity

- Order in which activities are to be performed

- Materials or chemicals to be used such as lubricant or solvent

- Records to be kept

- How to prevent cross-contamination

- Corrective actions for deviations

- Activity frequency

- Recording system

For calibration, the program should also identify:

- The maximum error allowed before corrective action (e.g. ±1 g; ±5°C)

- Corrective action to be taken when instrument does not meet specification

- Calibration methods based on approved standards

Record-keeping

Records are essential to the PMC program. Records can:

- Be based on records for each piece of equipment

- Be based on work orders and activities

- Software can be used to track activities

Your employer will have its own specific recording system for you to follow.

Record-keeping for Maintenance Activities

For regular maintenance, records need to indicate:

- Work order numbers

- Reason for the maintenance

- Equipment identification

- Maintenance activity (e.g. equipment inspection, adjustment and part replacement)

- Dates

- Person in charge

Record-keeping for Calibration Activities

When recording calibration activities, the following needs to be recorded:

- Instrument calibrated

- Date

- Person doing calibration

- Reason for calibration

- Findings from calibration

- Corrective action taken

Value of Good PMC Records

Good record-keeping allows planning for:

- Future maintenance activities

- Equipment retirement and purchase

- Provides evidence of due diligence in the case of failure

[h5p id=”39″]

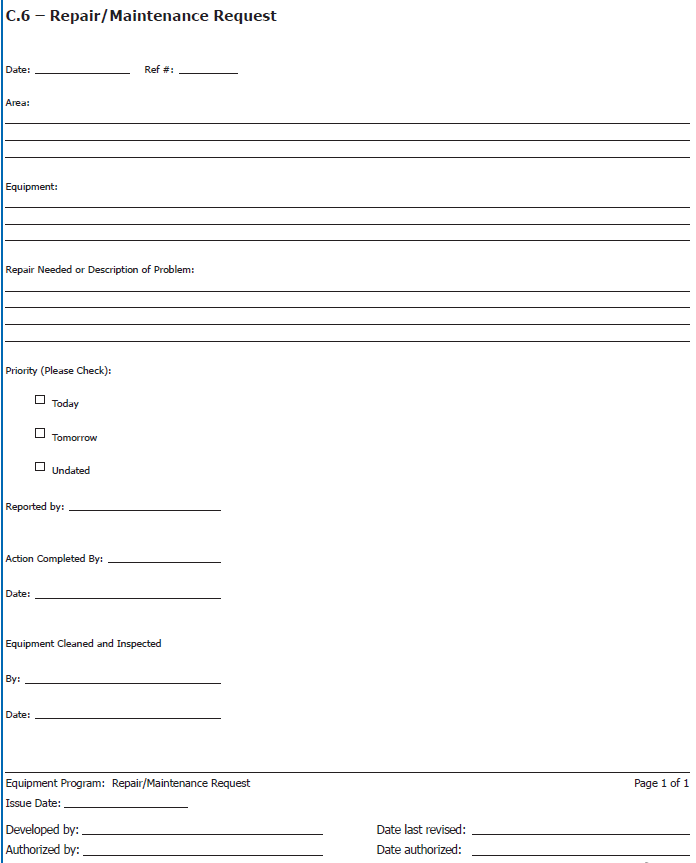

Recording a Failure

When maintenance requirement arises, a form similar to the following may be used by your employer to record the event.