1.6 Supply Chain Operations Reference (SCOR) Model

As we have seen in the previous sections, supply chain management involves coordinating a diverse set of functions within an organization, as well as managing relationships with a variety of external entities. This can quickly become complex, and managing this complexity effectively requires a system of standards, metrics, and procedures. Recognizing this need, the Supply Chain Council developed the Supply Chain Operations Reference (SCOR) model. This model has been updated as SCOR DS (Digital Standard).

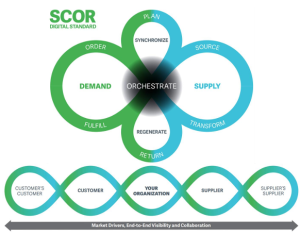

The SCOR model is a process reference model that provides a framework for evaluating and comparing supply chain activities. It encompasses all customer interactions, from order entry through paid invoice, as well as all product transactions, from supplier’s supplier to customer’s customer. SCOR DS address the complexities of modern, digital supply chains. Unlike its predecessor, which followed a linear approach, SCOR DS presents a dynamic, networked framework that reflects the interconnected nature of today’s supply chains.It includes the seven key components:

-

Orchestrate: Orchestrate is about managing the big picture across the entire supply chain—setting goals, aligning teams, and making sure all the moving parts (planning, sourcing, delivering, etc.) are working toward the same strategy. It’s like the role of a coach who doesn’t play in the game but makes sure the team works together, follows the game plan, and adjusts when needed. For example, a smartphone company uses real-time data from suppliers, factories, and sales to shift production from one model to another if it sees higher demand or a delay in a specific component.

-

Plan: Plan focuses on deciding how much of something to make, when to make it, and where to get the materials from, based on expected demand. It’s like planning your grocery shopping for the week—you check what you need, how many meals you’ll cook, and how much money you can spend. For instance, a bakery uses past sales data and seasonal trends to plan how many loaves of bread to bake each day and how much flour to order from suppliers.

-

Order: Order covers the steps that happen once a customer places an order, including checking product availability, confirming payment, and preparing the item for delivery. It ensures that what the customer wants is delivered quickly and accurately. For example, when someone orders a hoodie online, the system verifies that the size and color are in stock, confirms payment, and alerts the warehouse to pack and ship it.

-

Source: Source is about finding and buying the materials or parts a company needs to make its product. This includes choosing suppliers, negotiating prices, placing orders, and making sure deliveries arrive on time. A good sourcing process keeps production running smoothly. For example, a chocolate company sources cocoa from farms in Africa and ensures it arrives in time to meet holiday production schedules.

-

Transform: Transform is the stage where raw materials are turned into finished products, whether it’s assembling, manufacturing, or packaging. It includes quality checks and making sure the product meets design standards. For example, at a toy factory, plastic parts are molded, painted, and assembled into action figures that are then packaged for stores.

-

Fulfill: Fulfill is about getting the product into the customer’s hands. It includes picking products from the warehouse, packing them, and coordinating shipping and delivery. For example, an online bookshop receives an order, picks the book off the shelf, wraps it, and hands it off to a courier service to deliver to your home.

-

Return: Return deals with products that come back after being sold—maybe because they’re broken, expired, or no longer needed. It includes inspecting the returned item, processing refunds or replacements, and deciding what to do with the product (repair, recycle, or restock). For example, if someone returns a blender that doesn’t work, the company checks if it can be fixed and reused or must be discarded safely.

The SCOR DS model is useful for several reasons. It provides a standard description of supply chain processes, which facilitates communication and collaboration between different entities in the supply chain. It also provides a set of standard metrics for measuring supply chain performance, which allows organizations to benchmark their performance against industry standards and identify areas for improvement.

The SCOR DS model integrates both the entity view and the functional view of supply chains. From the entity view perspective, the SCOR DS model recognizes the importance of managing relationships with suppliers and customers, and it includes processes for sourcing materials from suppliers and delivering products to customers. From the functional view perspective, the SCOR model encompasses a range of internal functions, including planning, sourcing, making, delivering, and returning. By integrating these two views, the SCOR DS model provides a comprehensive framework for managing supply chains.

The SCOR DS model not only integrates the entity and functional views of supply chains, but it also emphasizes the importance of both internal and external alignment. Internal alignment refers to the coordination and collaboration among different functions within an organization, all working towards a common organizational goal. For instance, the marketing department must align with the operations department to ensure that the products being promoted are available in the right quantities at the right time. Similarly, the finance or accounting department must align with the purchasing department to ensure that procurement activities are within budget and that the necessary funds are available to pay suppliers on time. Conversely, the purchasing department must ensure that their purchases are within the budget set by the finance department. This alignment of functions towards a shared objective is crucial for the overall success of the organization.

External alignment, on the other hand, refers to the coordination and collaboration among different entities in the supply chain, such as suppliers, manufacturers, distributors, and retailers. Achieving external alignment can be challenging, as it often requires convincing external partners to align their strategies with the needs of the supply chain. For example, a clothing retailer may need to work closely with its suppliers to ensure they adopt sustainable practices, aligning with the retailer’s commitment to sustainability. If a supplier is unwilling or unable to adopt such practices, the retailer may need to seek out other suppliers who are better aligned with its supply chain needs.

The SCOR DS model provides a framework for achieving both internal and external alignment by standardizing processes, defining clear roles and responsibilities, and establishing performance metrics. This alignment is crucial for the smooth functioning of the supply chain and for achieving the ultimate goal of supply chain management: to deliver the right product, at the right time, at the right place, and at the right cost.

The structure of this textbook is designed around the SCOR model. The initial chapters will focus on strategy, quality, and sustainability, which are integral parts of the ‘Orchestrate’ and ‘Plan’ processes in the SCOR DS model. We will then move on to chapters dedicated to ‘Source’, where we will discuss various aspects of sourcing, including supplier selection, order management, and supplier performance monitoring.

Following this, we will delve into the ‘Transform’ process, discussing the transformation of products or services to meet demand. This will include topics such as production execution, quality assurance, and production scheduling. The subsequent chapters will focus on ‘Fulfillment’ and ‘Return’, covering topics such as order management, transportation management, distribution management, and the management of product returns. Throughout all these chapters, we will integrate the concept of ‘Enable’ by discussing relevant metrics and performance measures. This will provide you with a comprehensive understanding of how to manage and develop the business rules, performance metrics, data models, and practices that govern the operation of the supply chain.

As we embark on this journey together, we want to emphasize the importance and excitement of studying supply chain management. Regardless of your major or your future career path, understanding supply chains is crucial. Whether you’re a marketing major needing to ensure the right products are available for customers, a finance student wanting to control costs and book revenues, or a management student aiming to ensure the long-term success of a firm, supply chain knowledge is indispensable. So, let’s dive in and explore the fascinating world of supply chain management!

– Pause and Think –

- What is the purpose of the SCOR DS model in supply chain management?