7.3 How to Buy: Category Management and Kraljic’s Matrix

In the diverse and complex world of business procurement, companies typically purchase thousands of distinct products and services. It is impractical, if not impossible, to devise unique buying strategies for each item. To manage this complexity, businesses often resort to creating product categories, grouping similar items together and developing strategies for these categories. Examples of such categories might include office supplies (like stationery and furniture), IT equipment (computers, servers, software), raw materials (steel, plastics, chemicals), and professional services (consulting, legal services).

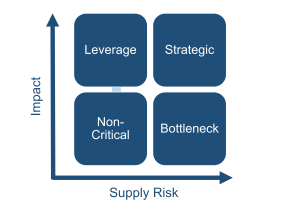

A widely recognized tool for shaping category strategies is Kraljic’s Purchasing Matrix. Developed by Peter Kraljic in 1983, this matrix helps businesses classify their purchases based on two key dimensions: supply risk and the importance of purchasing. Understanding these two dimensions is crucial for applying the matrix effectively.

Supply Risk Dimension:

- Low Supply Risk: This category includes standard components and services with many alternative vendors available in the market. The risk of supply interruption is low because these items are commonly produced and readily available. In this scenario, the buyer often holds a dominant position, as they have multiple sourcing options and can easily switch suppliers if necessary. Examples include standard office supplies or generic electronic components.

- High Supply Risk: This pertains to non-standardized components and services that are unique or have few suppliers. The risk of supply interruption is high due to the limited availability of these items. In such cases, the buyer needs to be more strategic and cautious, as their bargaining power may be lower. Examples can include specialized machinery parts or proprietary software services. The buyer’s strategy here should focus on securing supply and developing strong relationships with suppliers.

Importance to Purchasing Dimension:

- Low Importance and Value: These are items that, while necessary, do not significantly impact the company’s financials or operations. Due to their low purchasing value, suppliers might be less interested in maintaining these business relationships, as they contribute minimally to their revenue. An example could be minor office accessories.

- High Importance and Value: Items that have a substantial impact on the business’s operations or financial performance fall into this category. These are typically high-value purchases that are critical to the company’s success. Suppliers are usually more invested in these relationships due to the significance of the business. For these items, the suppliers are likely to be more responsive and offer better service, recognizing the mutual value of the relationship. Examples include key raw materials for manufacturing companies or large-scale IT infrastructure for tech firms.

Based on the two dimensions of supply risk and importance to purchasing, Kraljic’s Purchasing Matrix delineates four distinct quadrants of buying strategies. Each quadrant represents a different combination of supply risk and purchasing importance, guiding businesses in tailoring their procurement strategies accordingly.

- Non-Critical Items (Low Supply Risk, Low Importance): In this quadrant, items are easily replaceable and do not significantly impact the company’s operations or financial health. Businesses often consolidate such purchases, buying multiple non-critical items from a single supplier to create reasonable purchase value and streamline procurement processes. Since these items are standard and widely available, companies have the flexibility to switch suppliers without major disruptions. This approach not only simplifies the procurement process but also potentially leverages better pricing due to bulk buying. For example, a company might source all its basic office supplies like stationery, cleaning products, and generic electronic peripherals from one supplier to capitalize on volume discounts and minimize administrative costs.

- Leverage Items (Low Supply Risk, High Importance): Items in this category are crucial for business operations but are readily available in the market from several suppliers. The strategy here focuses on leveraging the company’s buying power to negotiate better prices and terms. Businesses can take advantage of the competitive market for these items to drive down costs while ensuring supply reliability. For instance, for IT equipment like laptops and servers, a company could negotiate favorable terms based on its large procurement volume, ensuring both cost efficiency and the availability of essential technology.

- Bottleneck Items (High Supply Risk, Low Importance): These items pose a high risk of supply interruption but are not vital to the company’s core operations. The strategy involves managing this risk by not overly pressuring suppliers, and actively working to develop alternative sources. Companies need to maintain good relationships with current suppliers while also identifying and nurturing relationships with potential new suppliers. For example, a specialized lubricant used in machinery might be sourced from a single supplier. The buying company would work to find alternate sources for this lubricant to mitigate the risk of supply disruption, while maintaining a positive relationship with the current supplier.

- Strategic Items (High Supply Risk, High Importance): This quadrant includes items that are critical to the business and have limited supply options. The focus here is on building strong, collaborative relationships with suppliers, often involving long-term contracts and joint development initiatives. Companies invest in understanding and improving these suppliers’ capabilities, thereby ensuring a stable supply of these crucial items. For instance, in the case of custom-made electronic components, a company might engage in long-term partnerships with suppliers, involving them in product development and quality assurance processes. This collaboration ensures a consistent supply of high-quality components, which are essential for the company’s products.

By categorizing procurement items into these quadrants, businesses can adopt a more nuanced and strategic approach to purchasing, aligning their procurement strategies with broader business objectives and effectively managing supplier relationships.