12.1 Introduction

In the complex journey of product and service delivery, a product must navigate through a myriad of resources before it reaches its final form. Consider a service example: a restaurant where dishes must pass through procurement of ingredients, preparation, cooking, and finally serving. In traditional business operations, there is a significant effort placed on planning and optimizing the capacity at every one of these resources. This involves meticulously calculating the maximum output each resource can deliver, ensuring that every part of the process is operating at peak efficiency to avoid delays and maximize productivity.

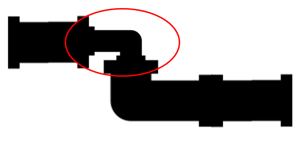

Figure 1: The bottleneck principle: The section of the pipe inside the oval will control the flow.

Theory of Constraints (TOC) presents a paradigm shift from traditional operational methodologies. TOC posits that the output of any system is fundamentally limited by its most constrained resource, or bottleneck. According to this theory, in any system, there are only a few elements that truly dictate its overall throughput. By identifying and focusing efforts on these critical bottlenecks, it becomes possible to control the entire system with greater efficiency and simplicity. Unlike the conventional approach that advocates for optimizing every resource, TOC concentrates on enhancing the performance of those few critical constraints.

In the context of our restaurant example, should a specific kitchen station emerge as the bottleneck by struggling to keep pace with demand, traditional strategies might aim to improve every stage of the service process. However, TOC would suggest a targeted approach, emphasizing optimization of this particular bottleneck. Instead of broad investments in speeding up table service or streamlining ingredient procurement, the emphasis would be on increasing the efficiency of the constrained kitchen station. Through this focused strategy, TOC significantly reduces the complexity involved in operations management, prioritizing impactful interventions that boost overall system productivity.

Dr. Eliyahu Goldratt introduced the concept of the Theory of Constraints (TOC) in his seminal work, “The Goal: A Process of Ongoing Improvement”. At the heart of TOC is the principle that the primary objective of any business should be to enhance the flow of its operations, a concept Goldratt describes as ‘throughput’. The book delineates straightforward, yet profoundly effective tools for increasing throughput, providing a blueprint for operational excellence.

Goldratt begins with the proposition of five focusing steps to implement TOC effectively. These steps are designed to systematically identify and address the bottlenecks that constrain a system’s performance. Following this, he introduces the ‘drum-buffer-rope’ (DBR) concept, a sophisticated method to ensure that processes remain within control by synchronizing operations with the system’s constraints. Lastly, Goldratt presents specific metrics that businesses can utilize to guide their improvement efforts, ensuring that they focus on initiatives that genuinely enhance throughput. In this chapter, we delve into these three pivotal tools offered by Goldratt.