16.1 Introduction

Business operations have grown increasingly complex due to the global distribution of customers, suppliers, and products, each interacting under a variety of legal systems and transacting in multiple currencies. This complexity arises not merely from the volume of transactions or the diversity of operational environments, but also from the intricacies of managing multi-faceted business relationships and regulatory compliance across different geographical locations.

Managing this complexity presents significant challenges. Organizations must navigate not only the logistics of supply chain operations but also the varied regulatory requirements and market dynamics of different regions. The difficulty lies in synchronizing these diverse elements to maintain efficiency and ensure the smooth flow of goods and information. Mismanagement can lead to delays, increased costs, and diminished service quality, affecting overall business competitiveness.

Consider the case of Ikea, the world’s largest furniture retailer. Their success relies on a massive global supply chain, sourcing materials from various countries and manufacturing products in dozens more. Ikea faces a multitude of challenges: navigating complex logistics across vast distances, complying with diverse environmental regulations (e.g., wood sourcing restrictions), and adapting product offerings to suit regional tastes and furniture styles. Synchronizing these diverse elements is a constant struggle. For example, a delay in receiving a key component from one supplier in Southeast Asia can hold up production in a European factory, impacting deliveries and customer satisfaction. Similarly, regulations restricting certain materials in one region might require Ikea to source alternatives or redesign products, adding complexity and cost.

In response to these challenges, technology becomes indispensable. Advanced information technology (IT) systems provide the tools necessary to integrate and manage business processes across the global supply chain. These technologies enable real-time data collection and analysis, improving decision-making and responsiveness. By leveraging IT, businesses can anticipate and mitigate disruptions, streamline operations, and enhance customer satisfaction.

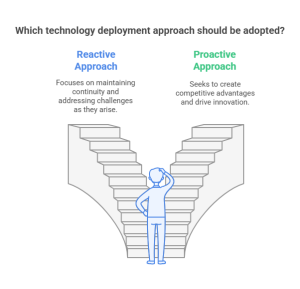

There are two primary approaches to deploying technology in business operations: reactive and proactive. A reactive approach focuses on countering challenges that arise due to operational complexity, inefficiencies, or external disruptions. It is aimed at maintaining business continuity, reducing risks, and improving resilience. Reactive technology adoption often includes solutions that enhance visibility, improve compliance, or address inefficiencies in supply chain operations. For example, many companies implement track-and-trace systems to comply with evolving regulations or respond to quality and safety concerns. Similarly, businesses might adopt automated inventory management to prevent stockouts after facing frequent supply disruptions.

In contrast, a proactive approach to technology adoption is about seeking new markets, creating competitive advantages, or fundamentally improving business capabilities. Rather than simply solving existing problems, proactive adoption leverages technology to open new opportunities and drive innovation. For instance, companies integrating predictive analytics for demand forecasting are not just solving inventory issues but are actively improving their ability to anticipate customer needs and optimize production schedules. Similarly, autonomous warehouse robotics are not just addressing labor shortages but are enabling businesses to scale operations at lower costs and with higher efficiency.

A common but often debated approach in technological adoption is “paving the cow path.” This term refers to the practice of applying new technology to existing processes without rethinking whether those processes should change. In other words, rather than redesigning workflows to take full advantage of new capabilities, organizations automate inefficient legacy processes. A classic example is paper-based purchase orders being digitized into PDFs instead of adopting an integrated procurement system that could streamline approvals and automate supplier communication. Similarly, companies implementing AI-powered customer support bots that replicate the same long wait times and rigid scripts of call centers fail to unlock the full potential of AI in personalizing customer interactions.

An alternative to paving the cow path is business process reengineering (BPR), which involves a fundamental redesign of workflows to maximize efficiency and innovation. Instead of merely applying technology to existing inefficiencies, BPR asks whether those processes should exist in their current form at all. For example, rather than using AI to speed up traditional supply chain documentation, some companies eliminate unnecessary paperwork entirely by adopting blockchain-based smart contracts, which automate transactions securely and transparently. Similarly, cloud-based ERP systems enable decentralized decision-making, allowing global teams to collaborate in real time instead of following hierarchical approval chains.

By distinguishing between reactive and proactive technology adoption and recognizing the trade-offs between paving the cow path and business process reengineering, companies can make more strategic decisions about technology investments. Businesses that simply apply new tools to outdated processes may find themselves improving efficiency but not fundamentally advancing their capabilities. Those that take a more transformational approach—redesigning processes to align with modern technology—can unlock far greater long-term benefits in supply chain management.