4.3 Supply Chain Practices

In the journey towards sustainability, businesses have to adopt certain practices that can help reduce their environmental impact. These practices are not just about reducing emissions or waste, but also about rethinking the way businesses operate and interact with the environment. In this section, we will explore four key sustainable practices: Ecological Footprint, Scope 1, 2, and 3 Emissions, Waste Hierarchy, and Circular Supply Chains.

4.3.1 Ecological Footprint

The ecological footprint is a measure of the environmental impact of a person, organization, city, or country. It quantifies the amount of nature’s resources an entity consumes and the waste it generates, compared to nature’s ability to regenerate those resources and absorb the waste. This measure is usually expressed in global hectares. Businesses, in their pursuit of sustainability, should ideally aim for Net Zero emissions. Net Zero refers to achieving a balance between the amount of greenhouse gases produced and the amount removed from the atmosphere. This can be achieved by reducing emissions and implementing practices to remove Greenhouse gases from the atmosphere.

Greenhouse gases (GHGs) are gases in the Earth’s atmosphere that trap heat. They let sunlight in but prevent some of the heat that the sunlight brings from leaving the atmosphere. The primary greenhouse gases in Earth’s atmosphere are water vapor, carbon dioxide (CO2), methane (CH4), nitrous oxide (N2O), and ozone (O3). While many of these gases occur naturally, human activities, particularly the burning of fossil fuels and deforestation, are increasing concentrations of some of them, such as CO2, leading to more heat being trapped and an overall warming of the Earth’s atmosphere. This understanding of GHGs lays the foundation for the concept of a carbon footprint, which is a critical component of an entity’s ecological footprint.

Carbon emissions are a significant component of an entity’s ecological footprint. Carbon footprint refers to the total amount of greenhouse gases produced, directly and indirectly, by an entity. It’s measured in units of carbon dioxide. Several companies have made commitments towards reducing their ecological footprint. For instance, Apple has committed to becoming 100% carbon neutral for its supply chain and products by 2030. This means that every Apple device sold will have net zero climate impact. Similarly, Microsoft has pledged to be carbon negative by 2030, meaning it plans to remove more carbon from the atmosphere than it emits.

4.3.2 Scope 1, Scope 2, and Scope 3 Emissions

Scope 1, 2, and 3 emissions are categories defined by the Greenhouse Gas Protocol to help organizations structure their greenhouse gas inventory. Scope 1 emissions are direct emissions from owned or controlled sources. Scope 2 emissions are indirect emissions from the generation of purchased energy. Scope 3 emissions are all indirect emissions that occur in the value chain of the reporting company, including both upstream and downstream emissions.

While Scope 1 emissions are often the primary focus, they can be less than 1% of a product’s total lifecycle emissions. Hence, it’s crucial for businesses to also focus on Scope 2 and 3 emissions. By doing so, they can identify more opportunities for reduction, engage suppliers and customers in their sustainability efforts, and make more informed decisions.

Science Based Targets (SBTs) are an effective tool in this regard. They provide a clearly defined pathway for companies to reduce greenhouse gas emissions in line with the Paris Agreement goals. By setting SBTs, companies can ensure their reduction efforts align with climate science, stimulate innovation, and enhance their reputations.

4.3.3 Waste Hierarchy

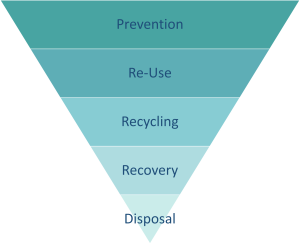

The waste hierarchy is a tool used in the evaluation of processes that protect the environment alongside resource and energy consumption from most favorable to least favorable actions. The hierarchy sets out preferred waste management practices, with prevention being the most desirable and landfill disposal being the least.

Businesses should aim to implement practices that are at the top of the hierarchy. For instance, they should focus on waste prevention, which involves redesigning products and processes and changing societal patterns of consumption and production. Next, they should consider waste minimization and reuse, then recycling, then energy recovery, and lastly disposal.

Many companies are now adopting practices such as remanufacturing, refurbishing, and recycling to reduce waste. Remanufacturing involves restoring a product to its original condition, using a combination of reused, repaired, and new parts. Refurbishing, on the other hand, involves a thorough check of products for defects and restoring them less expensively than remanufacturing. Recycling involves converting materials into reusable materials or returning them to their original state. These practices not only reduce waste but also save resources and energy, contributing to a more sustainable supply chain.

4.3.4 Circular Supply Chains

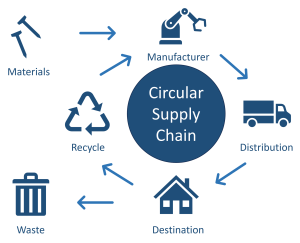

A circular supply chain refers to a system where the input materials are kept in circulation for as long as possible, extract the maximum value from them while in use, then recover and regenerate products and materials at the end of each service life. This is in contrast to the traditional linear economy, which has a ‘take, make, dispose’ model of production.

Circular supply chains can significantly reduce waste and make businesses more sustainable. They involve designing products for durability, reuse, and recyclability, using renewable or recycled materials, and reducing waste and pollution. For instance, Philips offers a service where they retain ownership of their medical equipment and take them back after use for refurbishment or recycling.

In conclusion, adopting sustainable practices in supply chains is not just about reducing the environmental impact. It’s also about creating value for businesses, improving efficiency, and building resilience in the face of environmental and social changes.