34 MAKING CONNECTIONS BETWEEN EVENTS: The Industrial Revolution

In the late 18th century, the world economy embarked on a rapid process of change. During this Industrial Revolution, new technologies greatly magnified the productivity of workers, while fossil fuels pushed manufacturing and transportation systems far beyond the natural limits of human and animal power. As these advances drove the cost of industrial production down, consumption of manufactured goods skyrocketed around the world.

The Industrial Revolution refers to a series of significant shifts in traditional practices of agriculture, manufacturing, and transportation, as well as the development of new mechanical technologies that took place during the late 18th and 19th centuries in much of the Western world. During this time, Great Britain, as well as the rest of Europe and the United States soon after, underwent drastic socio-economic and cultural changes.

The British textile industry drove the Industrial Revolution, triggering advancements in technology, stimulating the coal and iron industries, boosting raw material imports, and improving transportation, which made Britain the global leader of industrialization, trade, and scientific innovation. In a period loosely dated from the 1770s to the 1820s, Britain experienced an accelerated process of economic change that transformed a largely agrarian economy into the world’s first industrial economy. The changes were far-reaching and permanent throughout many areas of Britain, eventually affecting the entire world.

|

Watch and Learn |

|

Discover the Industrial Revolution as John Green discusses key developments in the late 18th century in Crash Course in World History #32.

|

The British Textile Industry

Before the 17th century, the manufacture of goods was performed on a limited scale by individual workers, usually on their own premises. Goods were transported around the country by clothiers who visited the village with their trains of packhorses. Some was made into clothes for people living in the same area and a large amount was exported. In the early 18th century, artisans were inventing ways to become more productive. Silk, wool, fustian (a cloth with flax warp and cotton weft), and linen were eclipsed by cotton, which was becoming the most important textile.

Most of the workforce was employed in agriculture, either as self-employed farmers as landowners or tenants, or as landless agricultural laborers. By the time of the Industrial Revolution the putting-out system in which farmers and townspeople produced goods in their homes, often described as cottage industry, was the standard. Typical putting-out system goods included spinning and weaving. Merchant capitalists provided the raw materials, typically paid workers by the piece, and were responsible for the sale of the goods. Workers put long hours into low productivity but labor-intensive tasks.

In the later part of the 18th century, there was a transition in parts of Great Britain’s previously manual labor and draft animal-based economy toward machine-based manufacturing. It started with the mechanization of the textile industries, the development of iron-making techniques, and the increased use of refined coal. Trade expansion was enabled by the introduction of canals, improved roads, and railways. Factories pulled thousands from low-productivity work in agriculture to high-productivity urban jobs.

Textiles have been identified as the catalyst of technological changes and thus their importance during the Industrial Revolution cannot be overstated. The application of steam power stimulated the demand for coal. The demand for machinery and rails stimulated the iron industry. The demand for transportation to move raw material in and finished products out stimulated the growth of the canal system, and (in the 19th century) the railway system. The introduction of steam power fueled primarily by coal, wider utilization of water wheels, and powered machinery in textile manufacturing underpinned the dramatic increases in production capacity. The development of all-metal machine tools in the first two decades of the 19th century facilitated the manufacture of more production machines for manufacturing in other industries. The effects spread throughout Western Europe and North America during the 19th century, eventually affecting most of the world.

The First Factories

The factory system was a new way of organizing labor made necessary by the development of machines, which were too large to house in a worker’s cottage and too expensive to be owned by the worker, who now labored long hours and lived under hazardous conditions in fledgling cities.

An image of an early factory in Great Britain known as the Soho Manufactory and build by Matthew Boulton (Source: Wikimedia)

Between the 1760s and 1850, the nature of work transitioned from a craft production model to a factory-centric model. Textile factories organized workers’ lives much differently than did craft production. Handloom weavers worked at their own pace, with their own tools, and within their own cottages. Factories set hours of work and the machinery within them shaped the pace of work. Factories brought workers together within one building to work on machinery that they did not own. They also increased the division of labor, narrowing the number and scope of tasks.

The textile industry, central to the Industrial Revolution, serves as an illustrative example of these changes. Prior to industrialization, handloom weavers worked at their own pace, with their own tools, within their own cottages. Now, factories set hours of work and the machinery within them shaped the pace. Factories brought workers together within one building to work on machinery that they did not own. They also increased the division of labor, narrowing the number and scope of tasks and including children and women within a common production process. The early textile factories employed a large share of children and women. In 1800, there were 20,000 apprentices (usually pauper children) working in cotton mills. The apprentices were particularly vulnerable to maltreatment, industrial accidents, and ill health from overwork and widespread contagious diseases such as smallpox, typhoid, and typhus. The enclosed conditions (to reduce the frequency of thread breakage, cotton mills were usually very warm and as draft-free as possible) and close contact within mills and factories allowed contagious diseases to spread rapidly. Typhoid was spread through poor sanitation in mills and the settlements around them. In all industries, women and children made significantly lower wages than men for the same work.

Work discipline was forcefully instilled upon the workforce by the factory owners, and the working conditions were dangerous and even deadly. Early industrial factories and mines created numerous health risks, and injury compensation for the workers did not exist. Machinery accidents could lead to burns, arm and leg injuries, amputation of fingers and limbs, and death. However, diseases were the most common health issues that had long-term effects. Cotton mills, coal mines, ironworks, and brick factories all had bad air, which caused chest diseases, coughs, blood-spitting, hard breathing, pains in chest, and insomnia. Workers usually toiled extremely long hours, six days a week.

With the onset of the Industrial Revolution in Britain in the late 18th century, there was a rapid increase in the industrial exploitation of labor, including child labor. The population grew and although chances of surviving childhood did not improve, infant mortality rates decreased markedly. Education opportunities for working-class families were limited, and children were expected to contribute to family budgets just like adult family members. Child labor became the labor of choice for manufacturing in the early phases of the Industrial Revolution in the 18th and 19th centuries. In England and Scotland in 1788, two-thirds of the workers in 143 water-powered cotton mills were described as children. Employers paid a child less than an adult even though their productivity was comparable. There was no need for strength to operate an industrial machine, and since the industrial system was completely new, there were no experienced adult laborers. Factory and mine owners preferred child labor also because they perceived the child workers’ smaller size as an advantage. In textile factories, children were desired because of their supposed “nimble fingers,” while low and narrow mine galleries made children particularly effective mine workers.

The early textile factories employed many children. Children started in the mills at around the age of four, working as mule scavengers under the working machinery until they were eight. They progressed to working as little piecers until they were 15. During this time, they worked 14 to 16 hours a day, often physically abused. By 1835, the share of the workforce under 18 years of age in cotton mills in England and Scotland had fallen to 43%. About half of workers in Manchester and Stockport cotton factories surveyed in 1818 and 1819 began work at under ten years of age. Most of the adult workers in cotton factories in mid-19th-century Britain started as child laborers.

Child labor existed long before the Industrial Revolution, but with the increase in population and education, it became more visible. Furthermore, unlike in agriculture and cottage industries where children often contributed to the family operation, children in the industrial employment were independent workers with no protective mechanisms in place. Many children were forced to work in very poor conditions for much lower pay than their elders, usually 10–20% of an adult male’s wage. Children as young as four were employed. Beatings and long hours were common, with some child coal miners and hurriers working from 4 a.m. until 5 p.m. Conditions were dangerous, with some children killed when they dozed off and fell into the path of the carts, while others died from gas explosions. Many children developed lung cancer and other diseases. Death before the age of 25 was common for child workers.

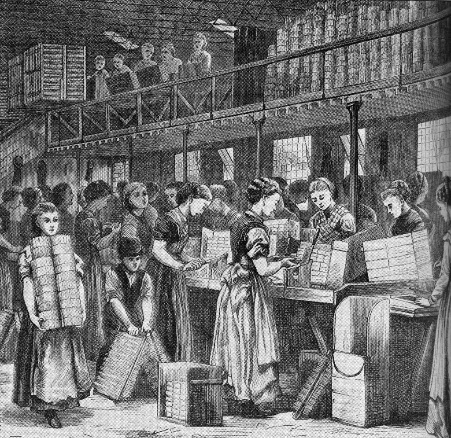

An image of women and girls working at a Match Factory (Source: Wikimedia)

Those child laborers who ran away would be whipped and returned to their masters, with some masters shackling them to prevent escape. Children employed as mule scavengers by cotton mills would crawl under machinery to pick up cotton, working 14 hours a day, six days a week. Some lost hands or limbs, others were crushed under the machines, and some were decapitated. Young girls worked at match factories, where phosphorus fumes would cause many to develop phossy jaw, an extremely painful condition that disfigured the patient and eventually caused brain damage, with dying bone tissue accompanied by a foul-smelling discharge. Children employed at glassworks were regularly burned and blinded, and those working at potteries were vulnerable to poisonous clay dust.

Workhouses would sell orphans and abandoned children as “pauper apprentices,” working without wages for board and lodging. In 1800, there were 20,000 apprentices working in cotton mills. The apprentices were particularly vulnerable to maltreatment, industrial accidents, and ill health from overwork and contagious diseases such as smallpox, typhoid, and typhus. The enclosed conditions (to reduce the frequency of thread breakage, cotton mills were usually very warm and as draft-free as possible) and close contact within mills and factories allowed contagious diseases such as typhus and smallpox to spread rapidly, especially because sanitation in mills and the settlements around them was often poor. Around 1780, a water-powered cotton mill was built for Robert Peel on the River Irwell near Radcliffe. The mill employed children bought from workhouses in Birmingham and London. They were unpaid and bound apprentices until they were 21, which in practice made them enslaved labor. They boarded on an upper floor of the building and were locked inside. Shifts were typically 10–10.5 hours in length (i.e., 12 hours after allowing for meal breaks) and the apprentices “hot bunked,” meaning a child who had just finished his shift would sleep in a bed just vacated by a child now starting his shift. Children as young as 4 were put to work. In coal mines, children began work at the age of 5 and generally died before the age of 25. Many children (and adults) worked 16-hour days.

Societal Impact

While child labor was common on farms and under the putting-out system, the impact of the factory system and the Industrial Revolution on children was damaging. In the industrial districts, children tended to enter the workforce at younger ages. Although most families channeled their children’s earnings into providing a better diet for them, the physical toll of working in the factories was too great and led to detrimental outcomes for children. Child laborers tended to be orphans, children of widows, or from the poorest families. Cruelty and torture was enacted on children by master-manufacturers to maintain high output or keep them awake. The children’s bodies become crooked and deformed from the work in the mills and factories.

Prior to the development of the factory system, in the traditional marriage of the laboring class, women would marry men of the same social status and marriage outside this norm was unusual. Marriage during the Industrial Revolution shifted from this tradition to a more sociable union between wife and husband in the laboring class. Women and men tended to marry someone from the same job, geographical location, or social group. The traditional work sphere was still dictated by the father, who controlled the pace of work for his family. However, factories and mills undermined the old patriarchal authority. Factories put husbands, wives, and children under the same conditions and authority of the manufacturer masters.

Factory workers typically lived within walking distance to work until the introduction of bicycles and electric street railways in the 1890s. Thus, the factory system was partly responsible for the rise of urban living, as large numbers of workers migrated into the towns in search of employment in the factories. Until the late 19th century, it was common to work at least 12 hours a day, six days a week in most factories, but long hours were also common outside factories.

Scholars continue to debate the question of how living conditions changed in the newly industrialized urban environment. A series of 1950s essays by Henry Phelps Brown and Sheila V. Hopkins set the academic consensus that the bulk of the population at the bottom of the social ladder suffered severe reductions in their living standards. Conversely, economist Robert E. Lucas, Jr., argues that the real impact of the Industrial Revolution was that the standards of living of the poorest segments of the society gradually, if slowly, improved. Others, however, have noted that while growth of the economy’s overall productive powers was unprecedented during the Industrial Revolution, living standards for the majority of the population did not grow meaningfully until the late 19th and 20th centuries and that in many ways workers’ living standards declined under early capitalism. For instance, studies have shown that real wages in Britain increased only 15% between the 1780s and 1850s and that life expectancy in Britain did not begin to dramatically increase until the 1870s.

Thus, the overall impact of the factory system and the Industrial Revolution more on adults is still the subject of disagreement. Optimists have argued that industrialization brought higher wages and better living standards to most people. Pessimists have argued that these gains have been over-exaggerated, wages did not rise significantly during this period, and whatever economic gains were actually made must be offset against the worsening health and housing of the new urban sectors.

Urbanization and Pollution

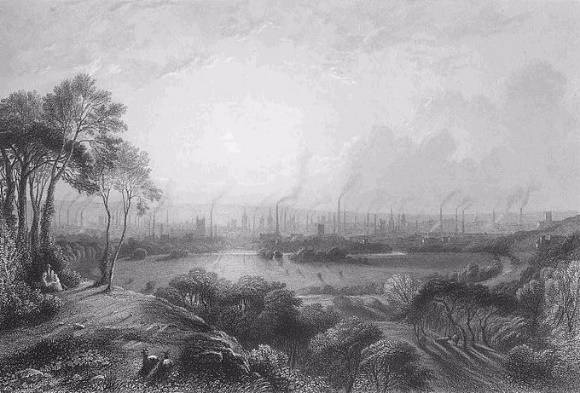

Industrialization and emergence of the factory system triggered rural-to-urban migration and thus led to a rapid growth of cities, where during the Industrial Revolution workers faced the challenge of dire conditions and developed new ways of living. Nowhere was this better illustrated than in Manchester, the world’s first industrial city which was nicknamed Cottonopolis because of its mills and associated industries that made it the global center of the textile industry. Manchester experienced a six-times increase in its population between 1771 and 1831. It had a population of 10,000 in 1717, but by 1911 it had burgeoned to 2.3 million.

An early 19th century engraving of Manchester showing the chimneys of the many factories spewing pollution into the air (Source: Wikimedia)

Chronic hunger and malnutrition were the norm for the majority of the population of the world, including Britain and France, until the late 19th century. Until about 1750, in part due to malnutrition, life expectancy in France was about 35 years, and only slightly higher in Britain. In Britain and the Netherlands, food supply had been increasing and prices falling before the Industrial Revolution due to better agricultural practices (in a process known as the “second Agricultural Revolution”).

Not everyone lived in poor conditions and struggled with the challenges of rapid industrialization. The Industrial Revolution also created a middle class of industrialists and professionals who lived in much better conditions. In fact, one of the earlier definitions of the middle class equated it to the original meaning of capitalist: someone with so much capital that they could rival nobles. To be a capital-owning millionaire was an important criterion of the middle class during the Industrial Revolution although the period also witnessed a growth of a class of professionals (e.g., lawyers, doctors, small business owners) who did not share the fate of the early industrial working class and enjoyed a comfortable standard of living in growing cities.

Finally, the emergence of great factories fueled by massive coal consumption also gave rise to an unprecedented level of air pollution in industrial centers. After 1900, the large volume of industrial chemical discharges added to the growing load of untreated human waste. In addition, the massive extraction of nonrenewable raw materials which were required to power industrial machinery (especially coal in the 18th century) altered the landscape in many places. The Industrial Revolution thus changed not only the lives of human beings, but also significantly impacted the ecological, atmospheric, and geologic history of the earth itself.